Rotating-vane type coarse filtering apparatus

A coarse-efficiency filter and rotary vane technology, which is applied to the air inlet of the turbine/propulsion device, charging system, engine components, etc., can solve the problem of increased pressure loss in the intake system, affecting the efficiency of the gas turbine, and the coarse-effect filter High cost and other issues, to achieve the effect of improving service life and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

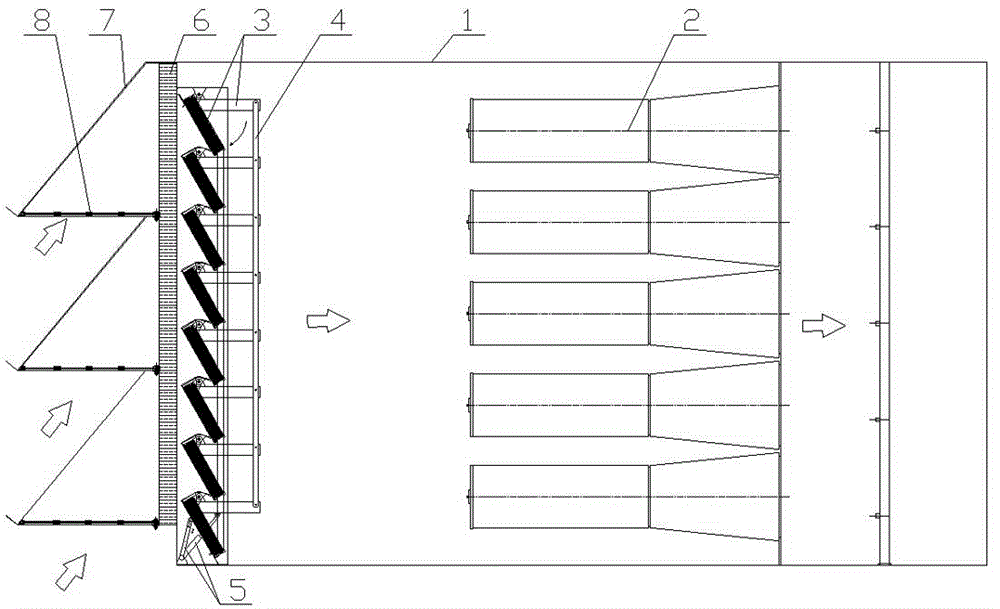

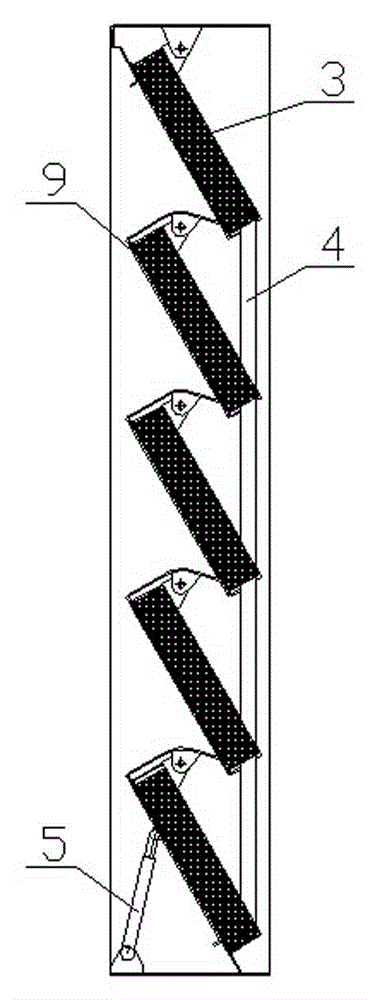

[0038] The rotary vane type coarse-effect filter device of this embodiment includes a coarse-effect filter device arranged in the air intake passage of the gas turbine, and the coarse-effect filter device includes a connecting rod and a plurality of coarse-effect filters arranged up and down, each The upper end of the coarse-effect filter is hinged in the intake passage, and the other end of each coarse-effect filter is hinged on the same connecting rod. The bottom surface of the coarse-effect filter located at the lowermost end of the intake passage is hinged with a telescopic cylinder or Hydraulic cylinder, the other end of the air cylinder or the hydraulic cylinder is hinged at the bottom end in the air intake passage.

Embodiment 2

[0040] The rotary vane type coarse-effect filter device of this embodiment includes a coarse-effect filter device arranged in the air intake passage of the gas turbine, and the coarse-effect filter device includes a connecting rod and a plurality of coarse-effect filters arranged up and down, each The upper end of the coarse-effect filter is hinged in the intake passage, and the other end of each coarse-effect filter is hinged on the same connecting rod. The bottom surface of the coarse-effect filter located at the lowermost end of the intake passage is hinged with a telescopic cylinder or Hydraulic cylinder, the other end of the air cylinder or the hydraulic cylinder is hinged at the bottom end in the air intake passage. The coarse-effect filter is hinged with the connecting rod through the connecting rod rotating shaft.

Embodiment 3

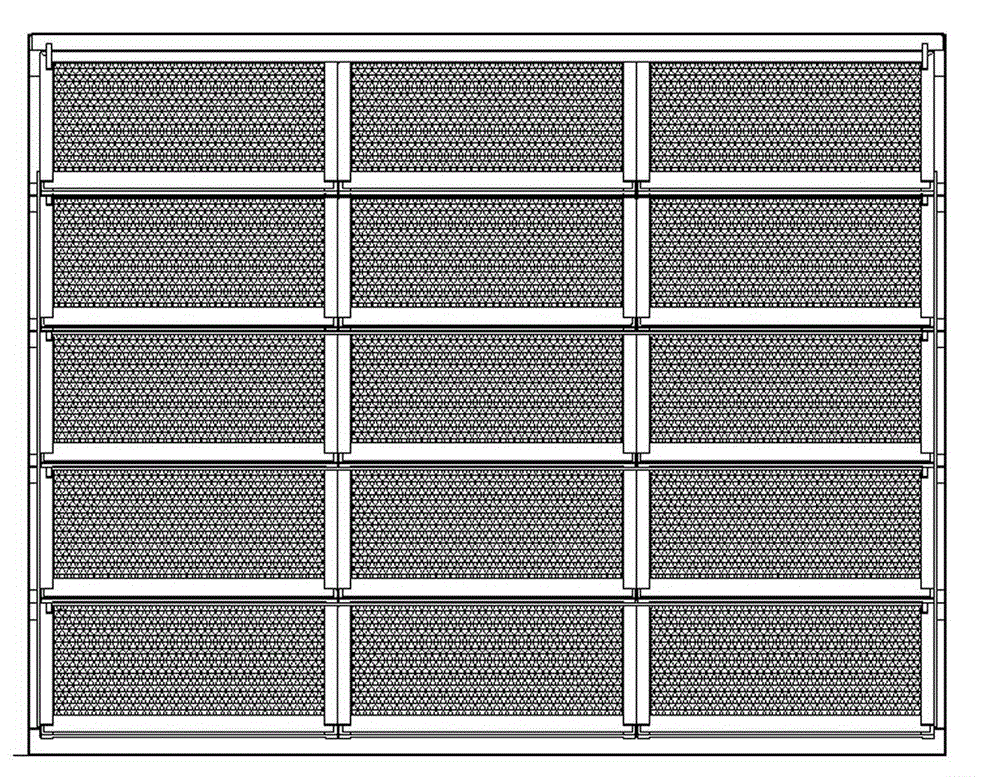

[0042] The rotary vane type coarse-effect filter device of this embodiment includes a coarse-effect filter device arranged in the air intake passage of the gas turbine, and the coarse-effect filter device includes a connecting rod and a plurality of coarse-effect filters arranged up and down, each The upper end of the coarse-effect filter is hinged in the intake passage, and the other end of each coarse-effect filter is hinged on the same connecting rod. The bottom surface of the coarse-effect filter located at the lowermost end of the intake passage is hinged with a telescopic cylinder or Hydraulic cylinder, the other end of the air cylinder or the hydraulic cylinder is hinged at the bottom end in the air intake passage. The coarse-effect filter is hinged with the connecting rod through the connecting rod rotating shaft. The periphery of the rough filter is covered with a sealing frame.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com