Thrust vector nozzle

A thrust vectoring and nozzle technology, applied in the field of aircraft, can solve the problem that the working life of the three-dimensional vector tail nozzle cannot meet the service requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

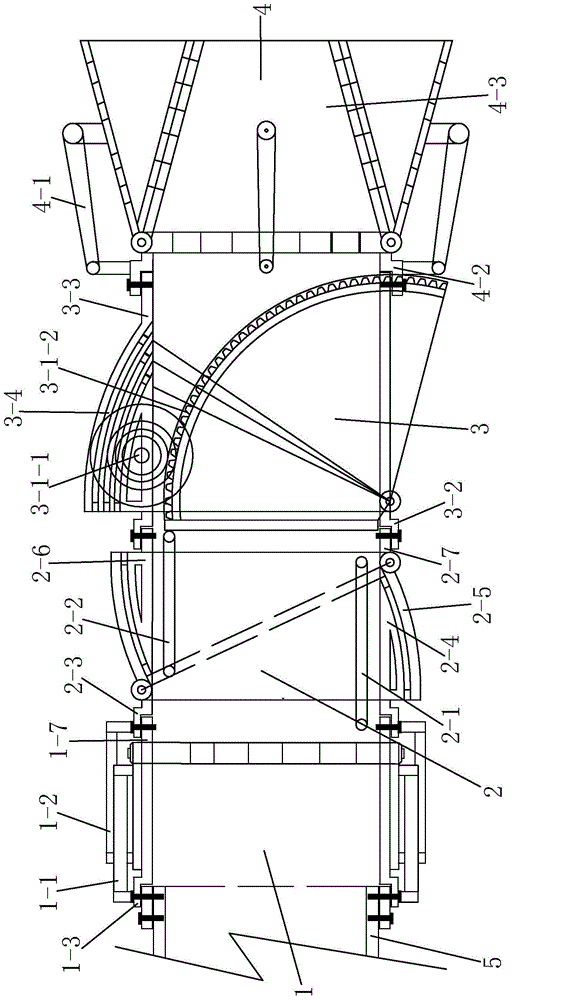

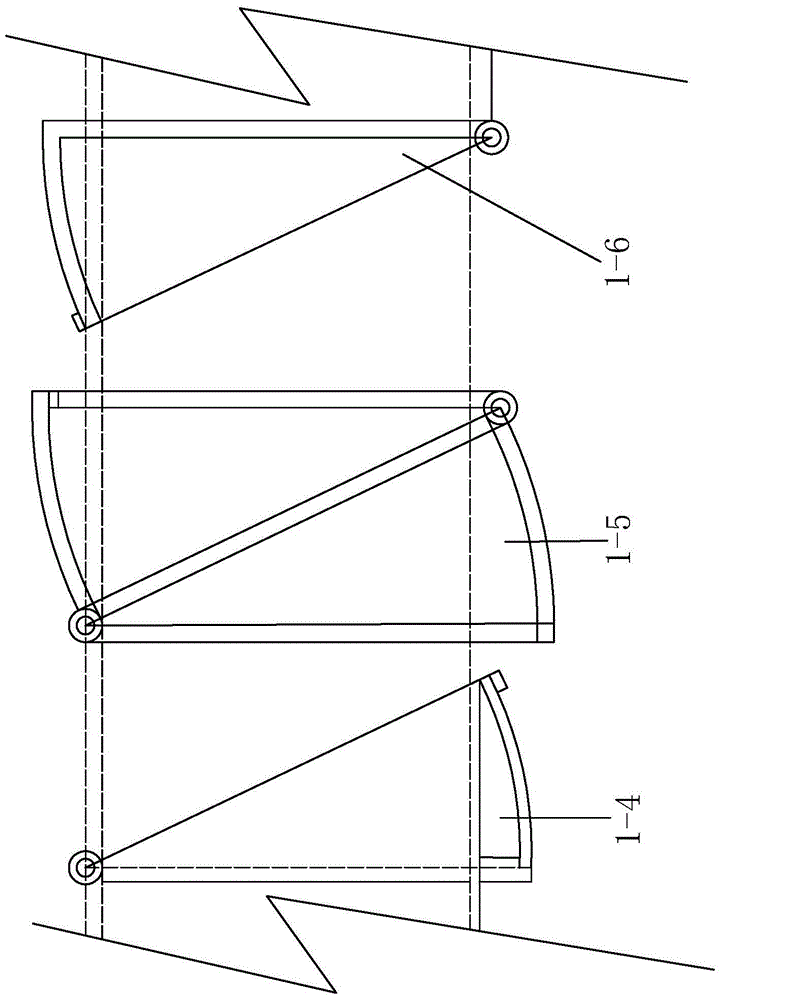

[0049] A thrust vectoring nozzle such as figure 1 As shown, it is mainly composed of 4 functional components, and these 4 functional groups start from the tail of the aircraft and are connected in series from front to back. The above four components are all made and socketed on the basis of square sleeves made of thin-walled plates, and they are in turn: the first functional component 1, that is, the left and right deflection functional sleeves and their hydraulic cylinders, which The function is to make the nozzle deflect left and right on the horizontal plane. The second functional component 2, that is, the vertical deflection functional casing and its hydraulic cylinder, has the function of making the nozzle deflect up and down. The third functional component 3, that is, the vertical downward deflection function casing and its hydraulic motor 3-1-1 actuating rack 3-1-2 assembly, its function is to make the nozzle vertically deflect downward and realize the nozzle The anti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com