Flange pipeline connection method based on electromagnetic control

It is a technology of electromagnetic control and connection method, which is applied in the direction of flange connection, pipe/pipe joint/fitting, passing components, etc. It can solve problems such as easy loosening or leakage, and affect pipeline safety, so as to achieve good airtightness and ensure safe operation. , the effect of tight connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

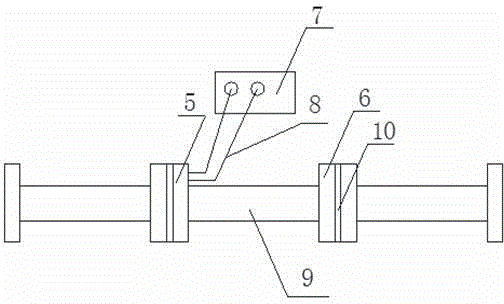

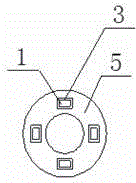

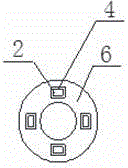

[0020] A flange pipe connection method using electromagnetic control, such as Figure 1-7 As shown, including electromagnet 1, iron ingot 2, insulating modules a3, b4, electromagnetic device 7 and gasket 10, four rectangular through holes are evenly distributed on the end face of flange a5 on one side of pipeline 9, each rectangular through hole An insulating module a3 with a rectangular through hole is embedded in the hole, the "dry" shaped electromagnet 1 is located in the insulating module a3, and four rectangular through holes are evenly distributed on the end face of the flange b6 on the other side of the pipeline, each An insulating module b4 with a rectangular through hole is embedded in the rectangular through hole. The "I" shaped iron ingot 2 is located in the insulating module b4. The rectangular through holes of the insulating module a3 and the insulating module b4 are provided with convex strips and respectively connected with The "dry" shaped electromagnet 1 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com