Thermal expansion structure of joint part of garbage incinerator

A waste incinerator and thermal expansion technology, which is applied in the direction of incinerator, combustion type, combustion method, etc., can solve the problems of easy ash leakage at the junction, pollution of the working environment on site, etc., and achieve the effect of ensuring sealing and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The thermal expansion structure of the junction of a garbage incinerator provided by the present invention has been funded by the National Science and Technology Support Program (project number: 2014BAC12B01).

[0016] The present invention will be further described below, but the present invention is not limited to the following examples.

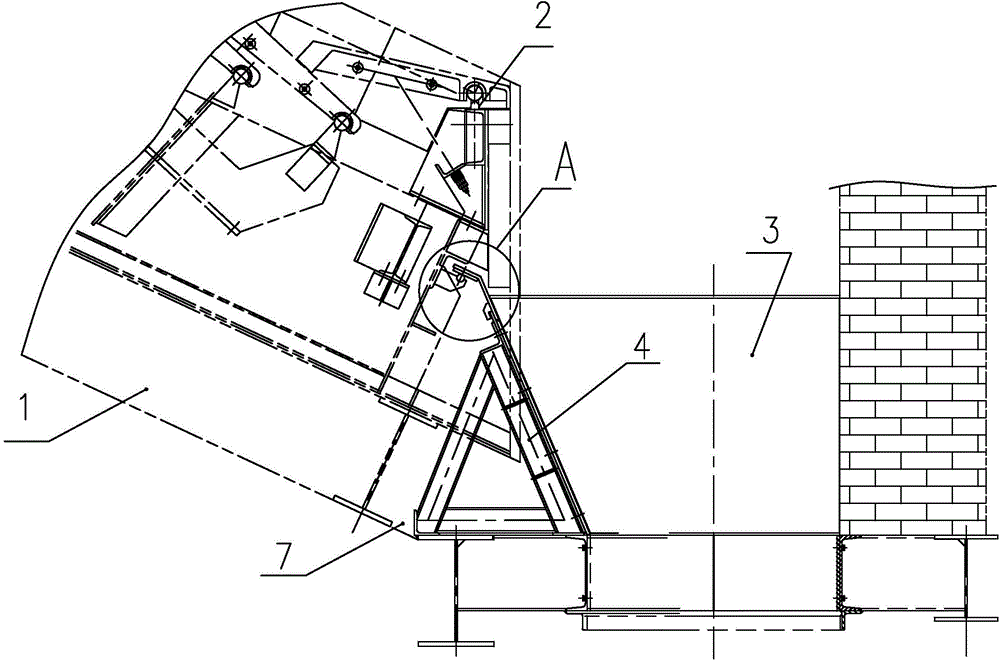

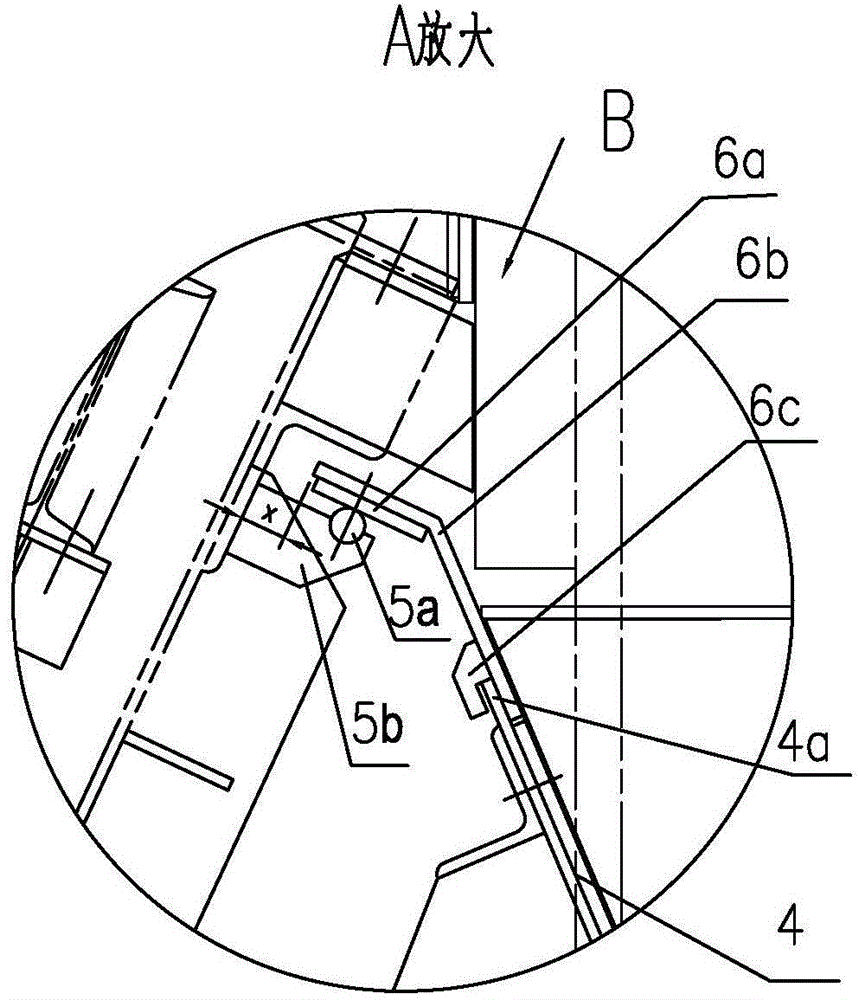

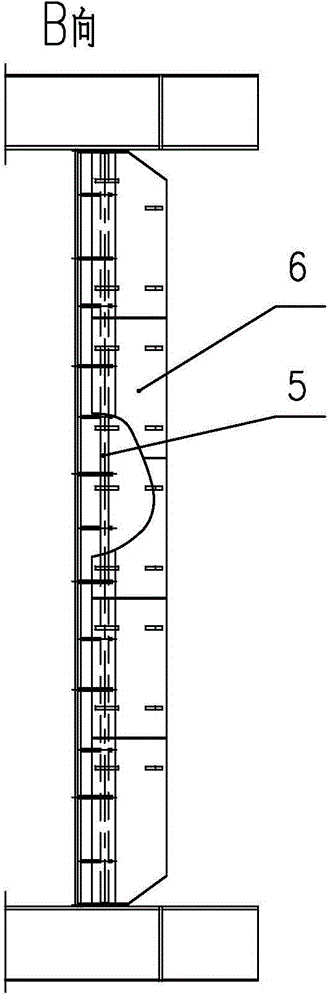

[0017] Such as figure 1 , 2 , 3, a thermal expansion structure of a garbage incinerator junction according to the present invention includes a steel frame 1, a thermal expansion component 2, a fixed component 3 and a thermal insulation sealing structure 7, and the thermal expansion component 2 and the fixed component 3 are composed of a steel frame 1 For support, the thermal insulation sealing structure 7 is provided at the junction of the thermally expandable component 2 and the fixed component 3 . A shelf 5 is fixed on the thermal expansion part, and the top of the shelf is a round steel 5a. A cover plate 6 is installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com