A Fault Diagnosis Method for Locomotive Wheelset Bearings Based on Angle-Time-Frequency Domain

A fault diagnosis and wheel set technology, applied in the direction of mechanical bearing testing, etc., can solve the problems of cumbersome fault diagnosis, inability to determine the location of bearing faults and quantitative judgment results, low diagnostic accuracy, etc., to achieve easy maintenance and promotion, real-time safety Monitoring and fault diagnosis, good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

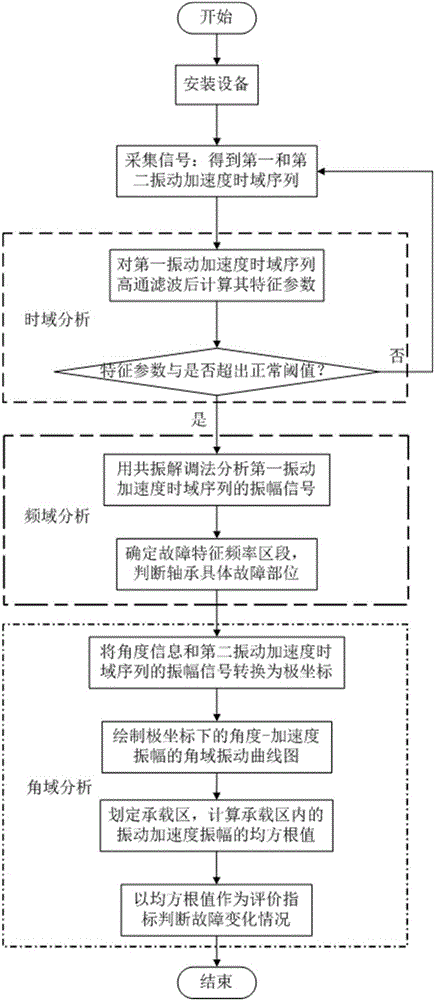

[0038] Depend on figure 1 with figure 2 It can be seen from the figure that a fault diagnosis method for locomotive wheel set bearings based on angle domain-time domain-frequency domain includes the following steps:

[0039] The first step is to install the equipment.

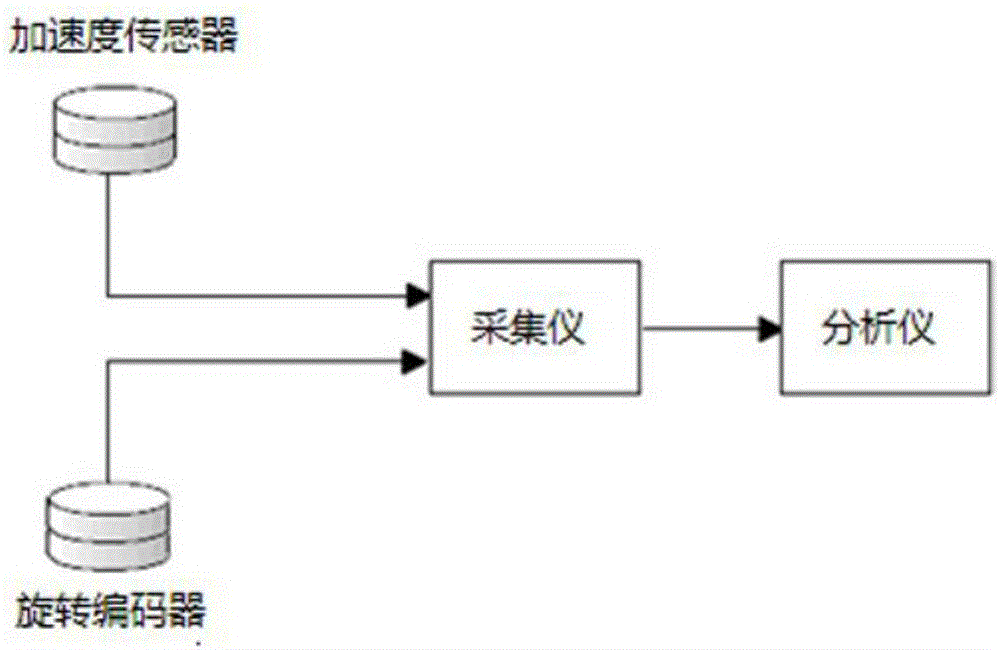

[0040] Install a rotary encoder at the end cover of the locomotive wheel set bearing; install an acquisition instrument and an analyzer in the locomotive driver's cab, and install an acceleration sensor directly above the locomotive wheel set bearing box. The output of the rotary encoder and the acceleration sensor is connected to the input of the acquisition instrument, and the output of the acquisition instrument is connected to the input of the analyzer; the rotary encoder, the acceleration sensor, the acquisition instrument and the analyzer are all connected by cables. Under certain circumstances, other wireless connection methods can also be used for connection, as long as the normal transmission of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com