Method and system for monitoring rope arrangement faults of drum steel wire rope on basis of machine vision

A technology of machine vision and fault monitoring, applied in the testing of machines/structural components, instruments, measuring devices, etc., can solve problems such as lack of objectivity and insufficient intelligence, and achieve the elimination of potential safety hazards, low requirements for the use environment, and mathematical Model Simple Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

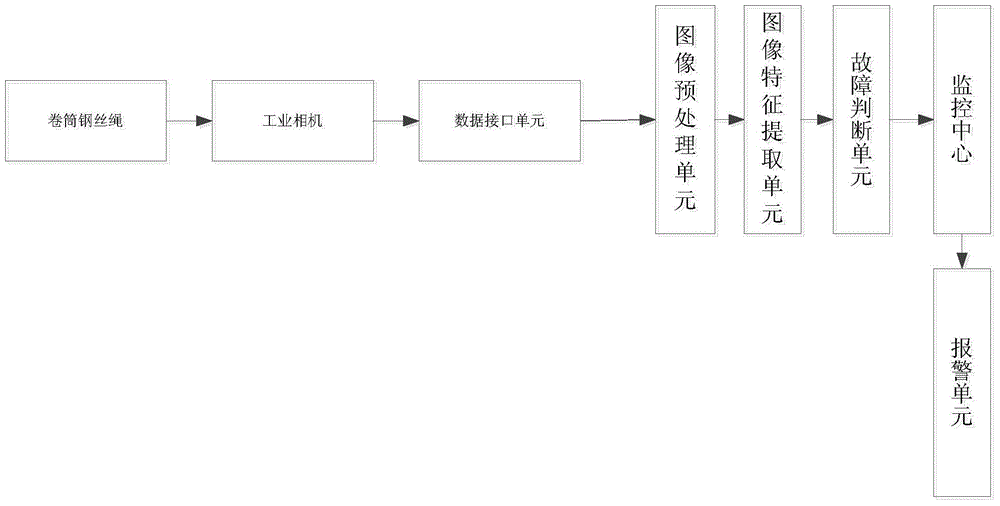

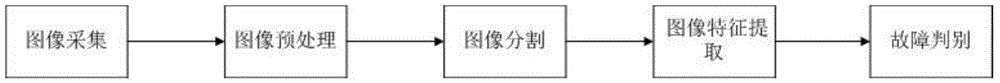

[0043] Such as figure 2 As shown, a machine vision-based method for detecting faults in drum wire rope arrangement includes the following steps:

[0044] Step 1: Fix the industrial camera 8 on the back of the roll 9, and the roll is fixed on the installation base, such as Image 6 As shown, the imaging area of the industrial camera covers the rope-laying area of the drum wire rope;

[0045] Step 2: Calibrate the industrial camera to obtain the actual distance calibration parameters represented by the unit pixel of the industrial camera;

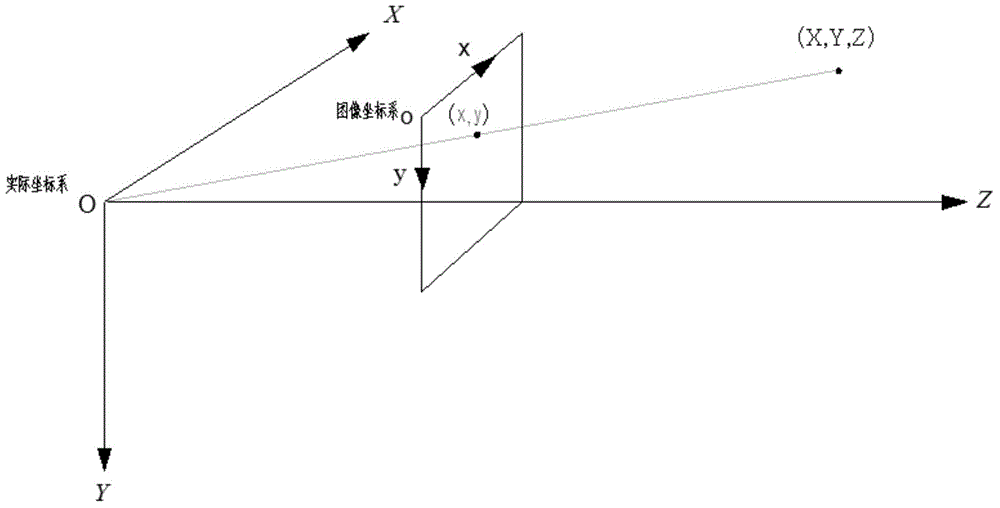

[0046] From the extracted pixel coordinates to the calculation of the actual center distance, the system needs to establish the image plane coordinate system and the actual coordinate system, such as image 3 As shown in , the geometric constraints corresponding to the two coordinates are solved by automatic ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com