Short-span tapered strain clamp for ADSS optical cable

A tension clamp, optical cable technology, applied in the direction of optical fiber/cable installation, etc., can solve the problems of poor adaptability of pre-twisted metal fittings, easy to cause safety accidents, and the grip strength cannot meet the requirements, so as to eliminate potential safety hazards and adhesion. The effect of good integration and reduction of the probability of safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

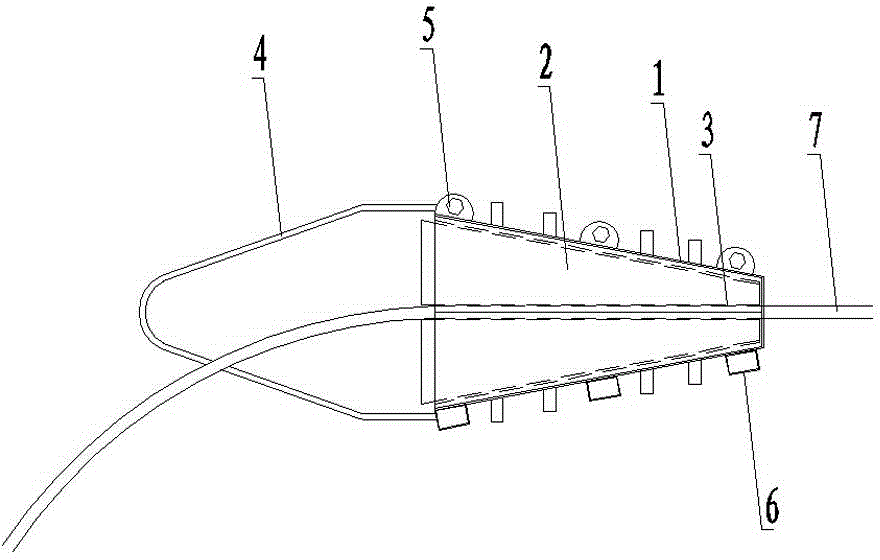

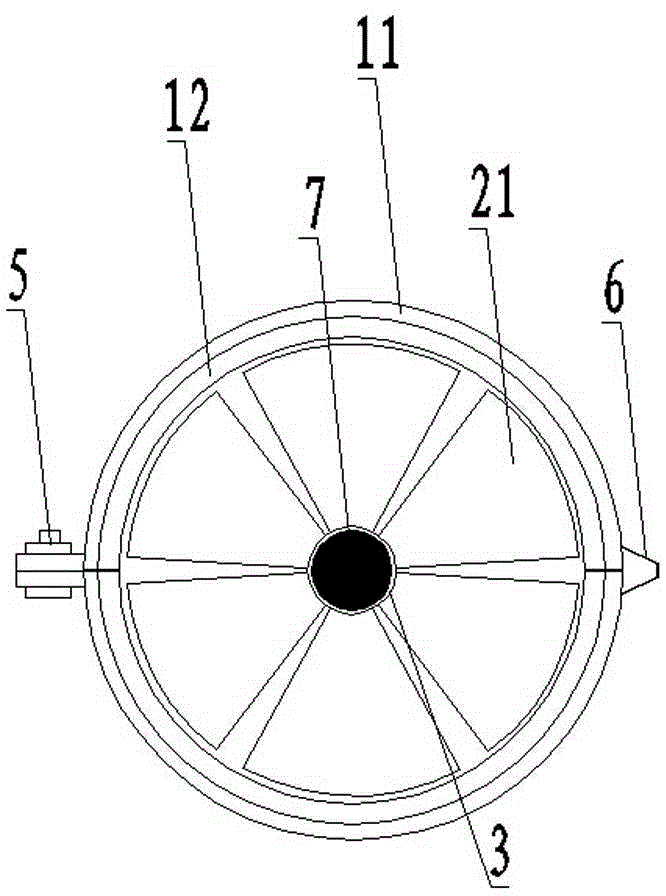

[0023] The outer casing 11 of the present invention is a high-strength aluminum alloy casing, and the inner interlayer 12 and the combination wedge 2 are made of weather-resistant engineering plastics. The inner interlayer 12 and the outer casing 11 are tightly combined and cannot slide, and the combination wedge 2 can The interlayer 12 slides inside and is used to hold the optical cable 7. The outer shell 11 and the combination wedge 2 are matched in a cone shape, and its holding force can reach about 11KN, which is equivalent to the rated tensile strength of the ADSS optical cable under the weather conditions of 100m span and 10mm ice thickness. Strength, can form a stable and qualified grip on the optical cable 7 in the center, so it is suitable for short-span ADSS optical cables; its small size and short length reduce the length of the tensile force on the optical cable 7 by nearly 70%, and will not form stress concentration , eliminating the potential safety hazards caused...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com