Handheld type yarn technology optimizing device and work process thereof

A hand-held, yarn-based technology, applied in the direction of program control, comprehensive factory control, comprehensive factory control, etc., can solve problems that affect economic benefits and market competitiveness, and cannot adjust yarn production process parameters in time and accurately, so as to reduce labor The effect of cost, low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

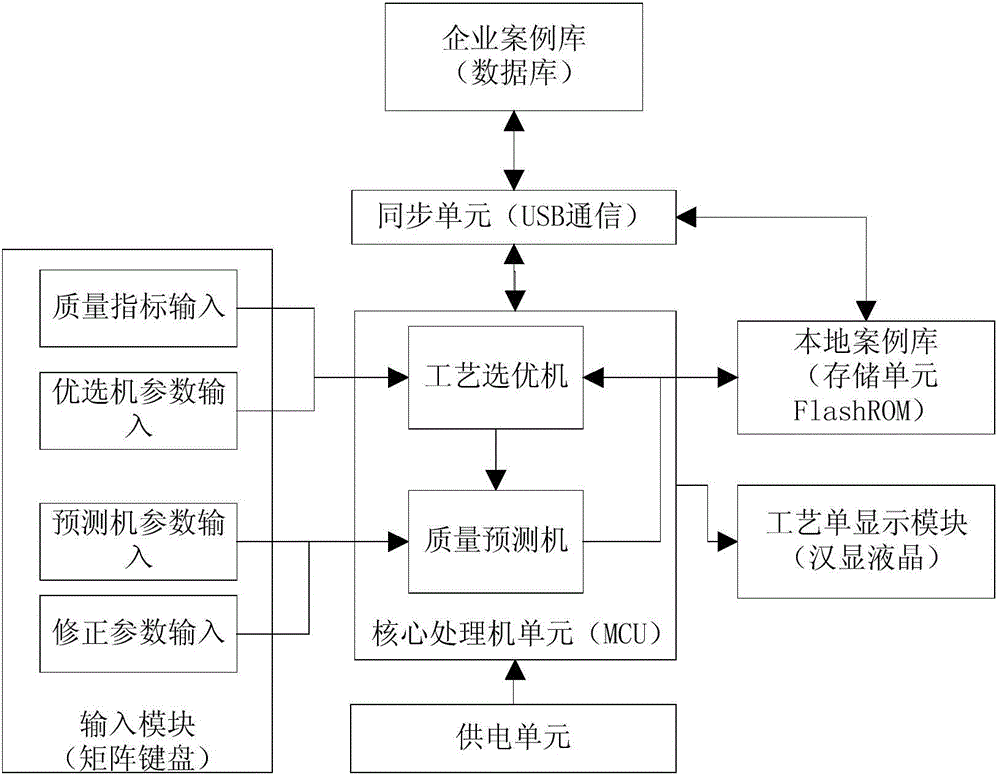

[0036] Such as figure 1 The preferred device for a hand-held yarn process shown includes

[0037] The core processing unit is composed of an embedded microcontroller and peripheral circuits. The core processor unit is composed of an embedded microcontroller and peripheral circuits. The core processor runs the two core modules of the process optimization machine and the quality prediction machine, and controls the input output module, storage unit and interface circuit;

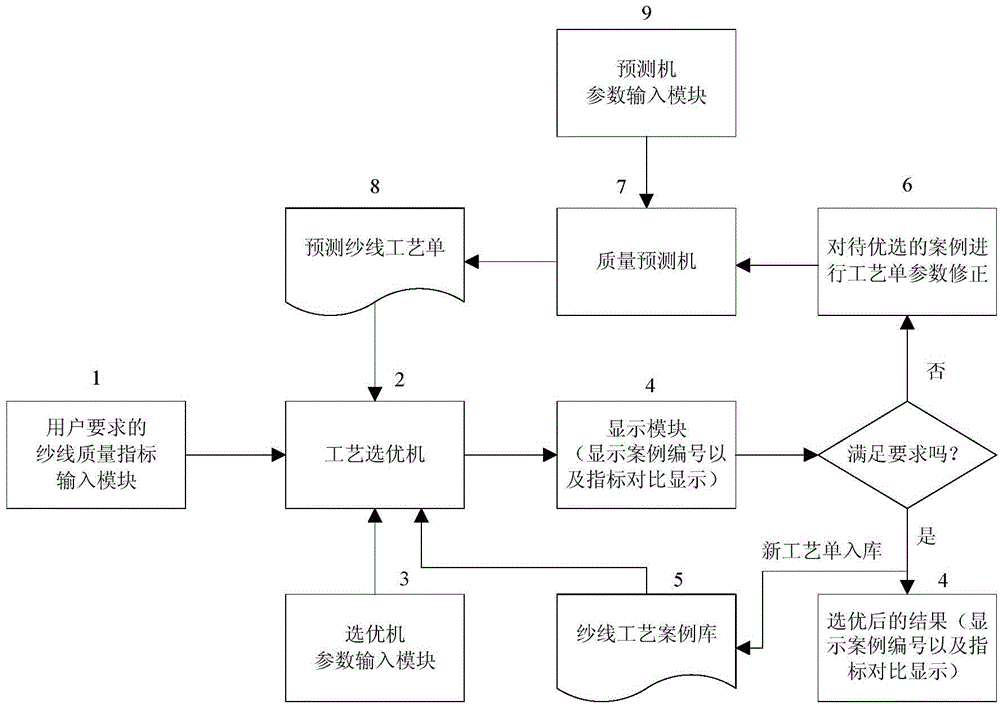

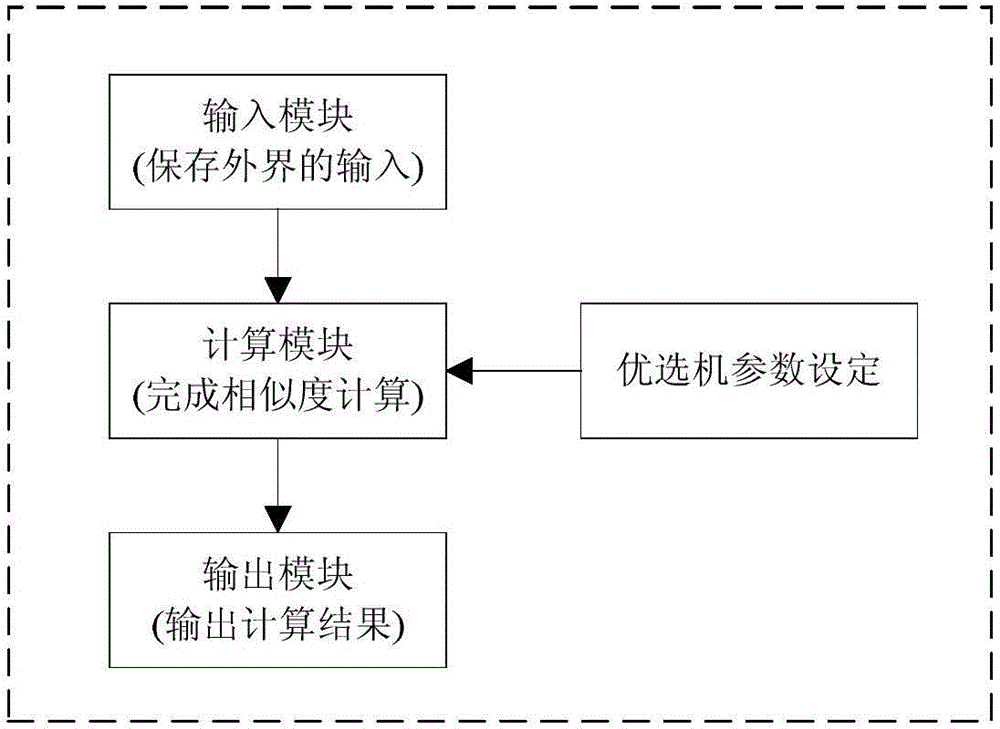

[0038] The structural principle diagram of the process optimization machine in this structure is as follows image 3 As shown, the optimization machine actually uses the principle of case-based reasoning (CBR), according to the weight of each attribute in the yarn quality index, calculates the similarity of each case sequentially from the historical target case library, and retrieves Several cases that are most similar (maximum similarity) to the case to be solved are provided for reference by designers. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com