Laser film audio cable and processing technology thereof

A technology of laser film and audio cable, which is applied in the field of laser film audio cable and its processing technology, can solve the problems of insufficient aesthetics of audio cable, single appearance, inconvenient use, etc., and achieve the effect of beautiful appearance, convenient process and high identification degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

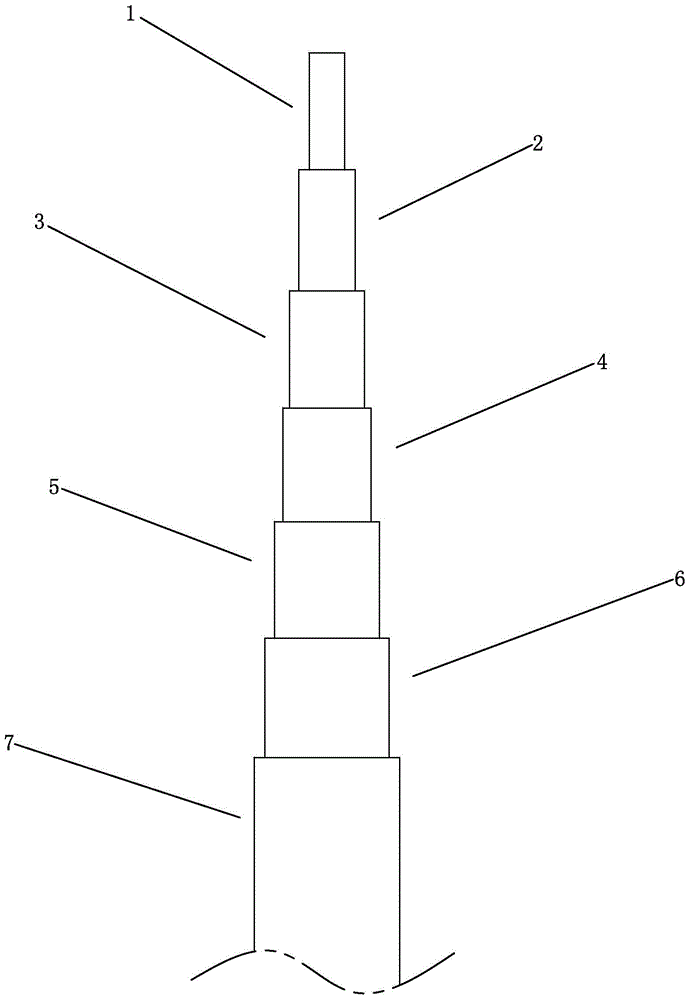

[0017] refer to figure 1 , a laser film audio cable of the present invention, comprising a conductor core 1, an insulating layer 2, a shielding layer 4, an inner lining layer 5 and a sheath layer 7, and the conductor core 1 and the shielding layer 4 both include copper wire and an antenna Plain wire, black conductive PE material 3 is arranged between the insulating layer 2 and the shielding layer 4, a laser film 6 is arranged between the inner lining layer 5 and the sheath layer 7, and the sheath layer 7 is a transparent material. While ensuring the signal conduction performance and structural performance of the audio cable, a laser film 6 is added in the sheath layer 7. Through the transparent sheath layer 7, the laser film 6 can transmit flickering light, which is very easy to detect.

[0018] As a further improvement, the laser film 6 is formed by winding a laser line with a width of 1.8-2.2 mm, and the wire core 1 is provided with 20 copper wires with a diameter of 0.10-0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com