Composite superconducting plate heat pipe power battery heat management system

A thermal management system, power battery technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as failure and reduction of power battery life, achieve simple structure, increase service life and stability, installation and increase or decrease handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

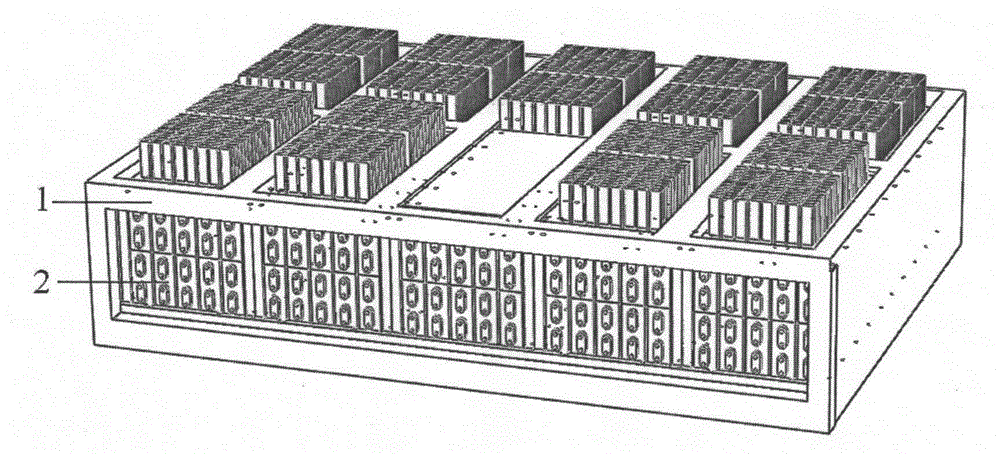

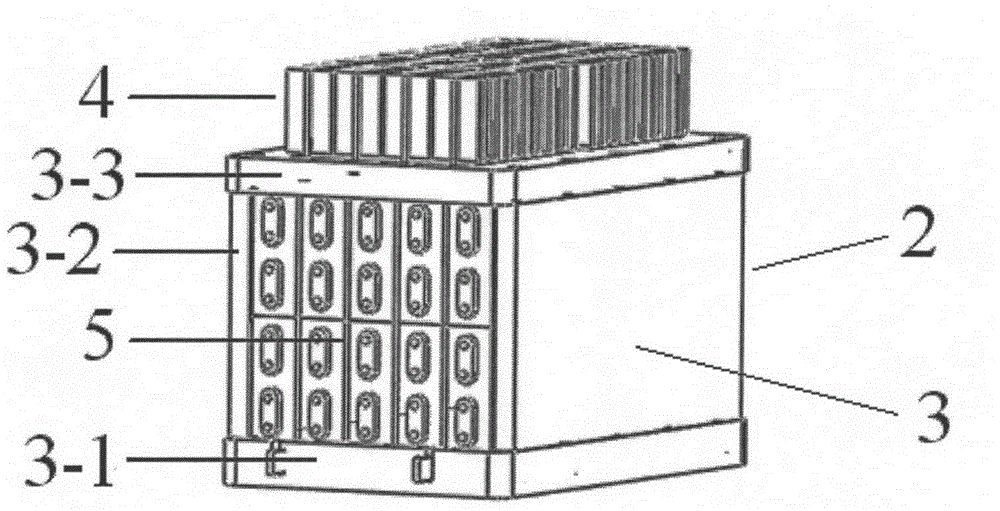

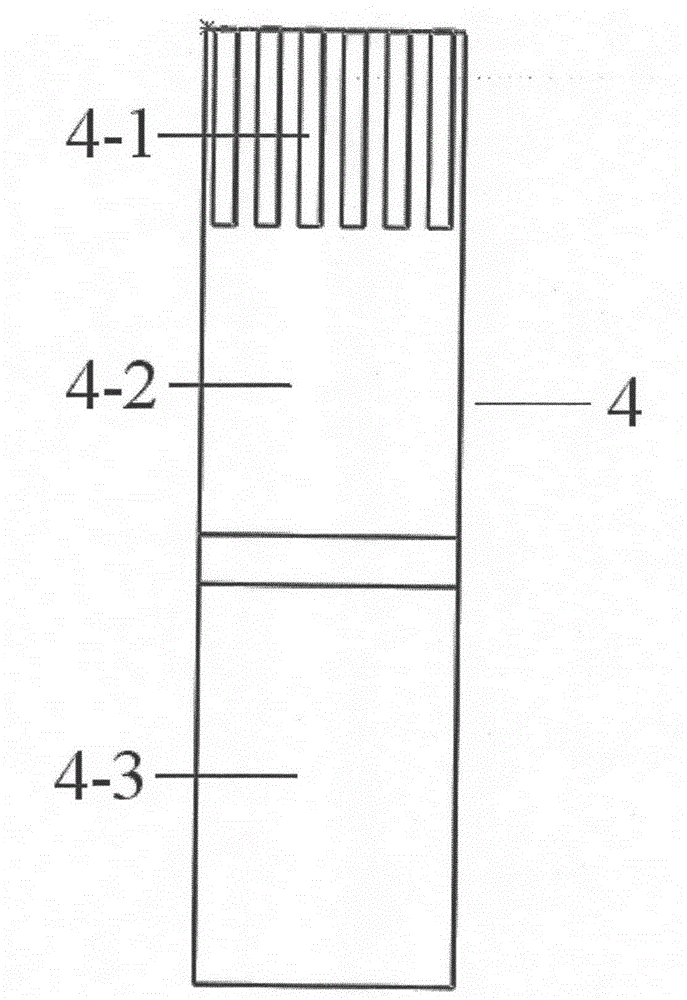

[0026] like Figure 1-9 As shown, it is a schematic structural diagram of a composite superconducting flat heat pipe power battery thermal management system provided by the present invention, including a casing 1, and at least one power battery box 2 is arranged in the casing 1. , the box 3 is provided with a plurality of composite superconducting flat heat pipe radiators 4 and power batteries 5 arranged at intervals, and two adjacent composite superconducting flat heat pipe radiators 4 are provided with two upper and lower overlapping power batteries 5 , the connection terminals of the two power batteries 5 are arranged in the horizontal direction on the same side. Box 3 such as Figure 5 As shown, it includes a heating bottom plate 3-1 at the bottom, baffle plates 3-2 on both sides, a box top cover 3-3 at the top, and a heating device 7. The power battery power battery 5 is located in the box top cover 3-3 and the heating device. Between the bottom plates 3-1, the heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com