Antifouling Hard Coats and Antifouling Hard Coat Precursors

A hard coating and nanoparticle technology, applied in coatings, nanotechnology, etc., can solve the problems of deterioration of antifouling properties of hard coatings, and achieve the effects of increased durability, excellent scratch resistance and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

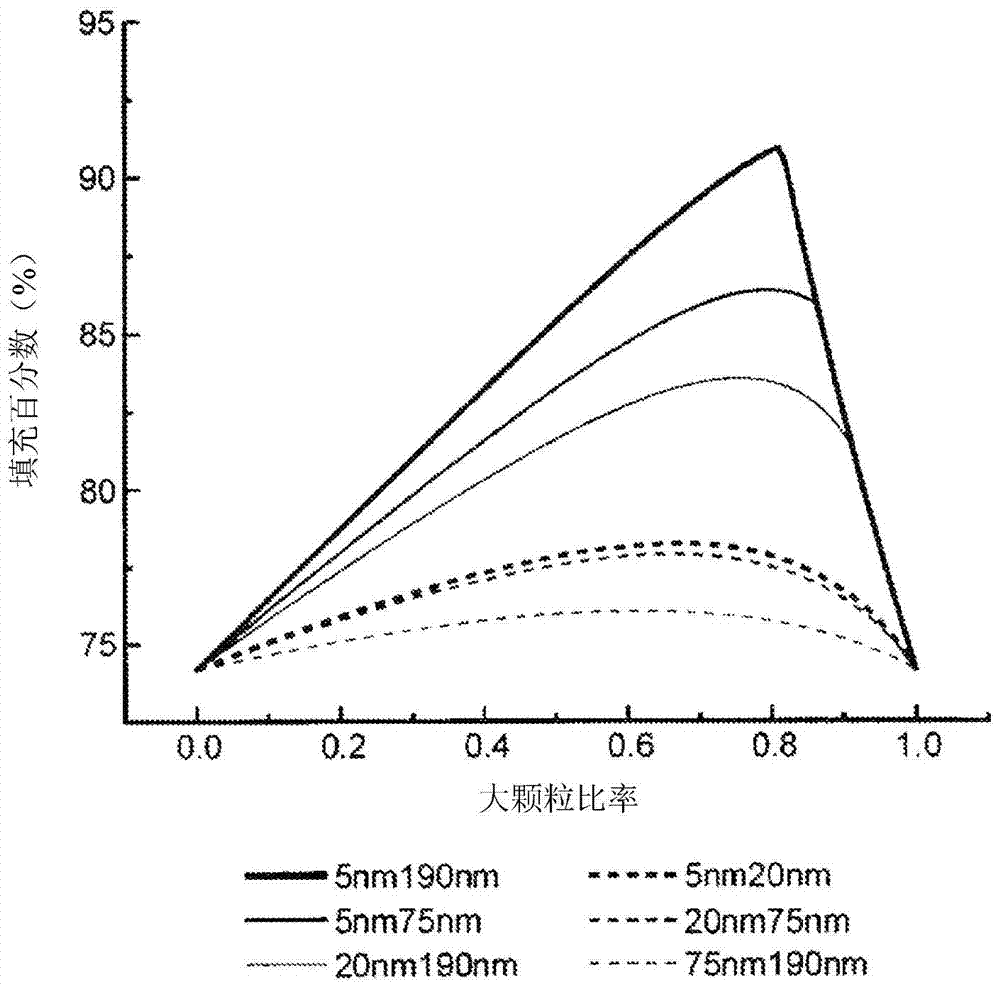

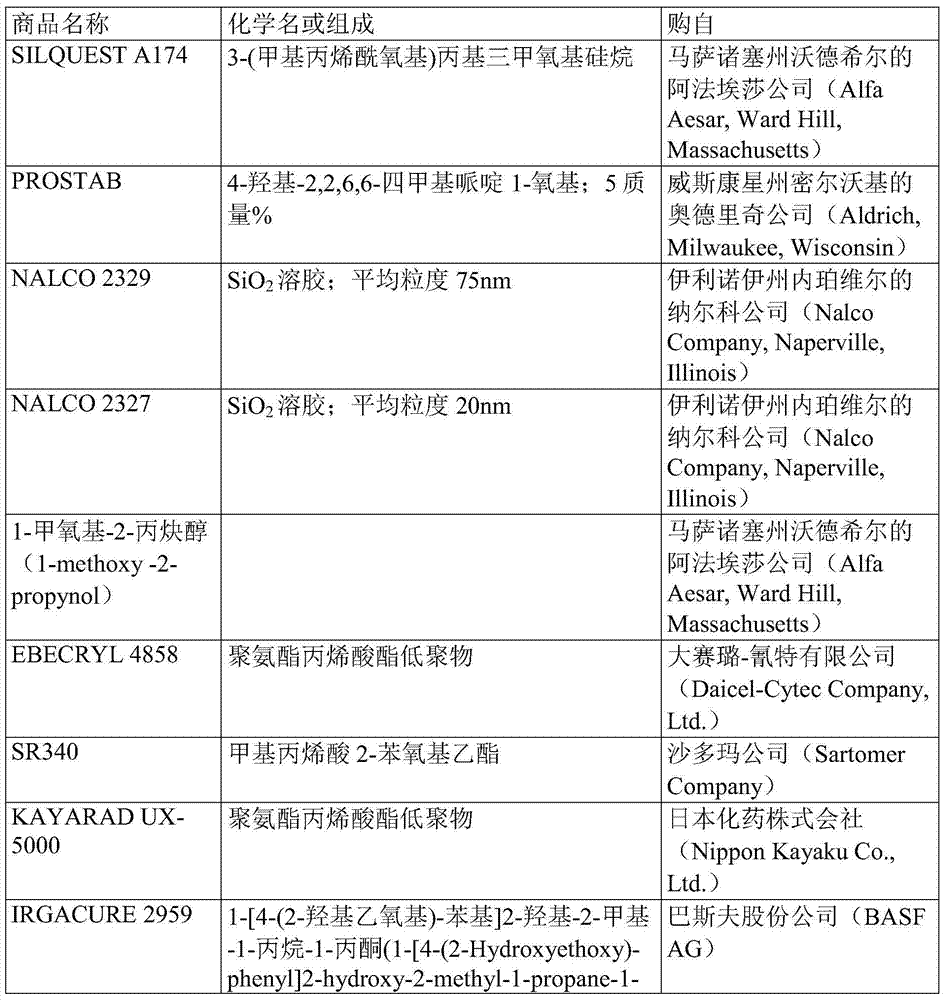

[0079] Example 1 is a hard coat layer comprising a mixture of nanoparticles and a binder; the nanoparticles constitute 40% to 95% by mass of the entire mass of the hard coat layer; 10% to 50% by mass of the nanoparticles have The average particle size in the range; 50% to 90% by mass of nanoparticles has an average particle size in the range of 60nm to 400nm; the average particle size of nanoparticles with an average particle size in the range of 60nm to 400nm The ratio of the average particle size of the nanoparticles within the average particle size ranges from 2:1 to 200:1; the particle size distribution of the nanoparticles is bimodal or multimodal; the binder comprises a multifunctional fluorinated (methyl ) acrylic compounds, their reaction products, or combinations thereof; wherein the multifunctional fluorinated (meth)acrylic compound comprises cyclic siloxane units.

Embodiment 2

[0080] Embodiment 2 is the hard coat of embodiment 1, wherein the nanoparticles are surface-modified nanoparticles.

Embodiment 3

[0081] Embodiment 3 is the hard coat layer of embodiment 1 or embodiment 2, wherein the multifunctional fluorinated (meth)acrylic compound is a perfluoroether compound having two or more (meth)acrylic acid groups.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com