Modified polyimide film and preparation method thereof

A polyimide film and modification technology are applied in the field of modified polyimide film and its preparation, which can solve the problem of polyimide thermal stability and mechanical properties decline, colorless and transparent polyimide film fog In order to achieve the effect of low birefringence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

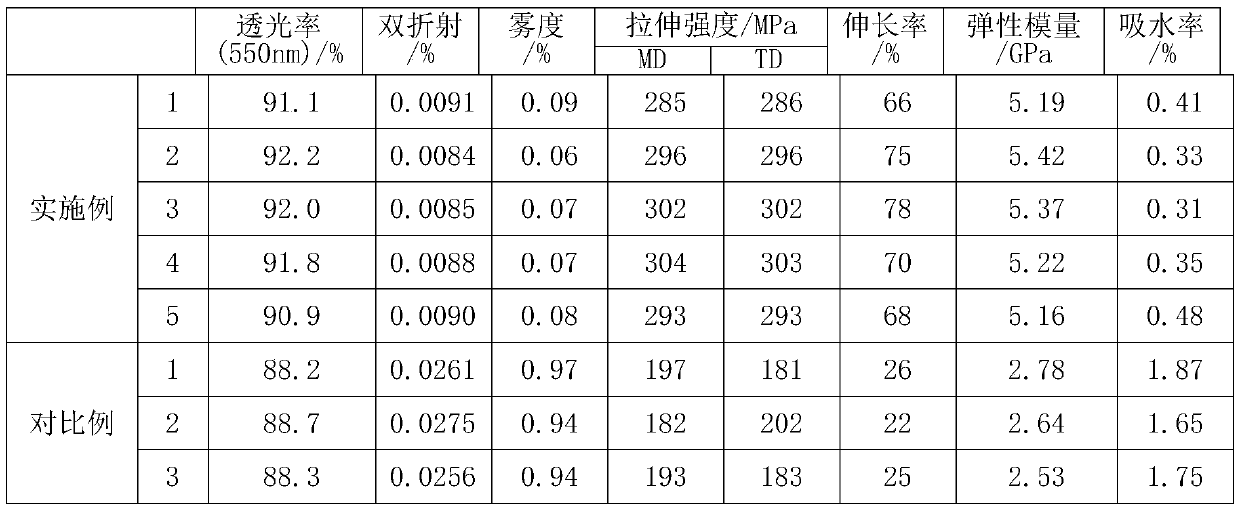

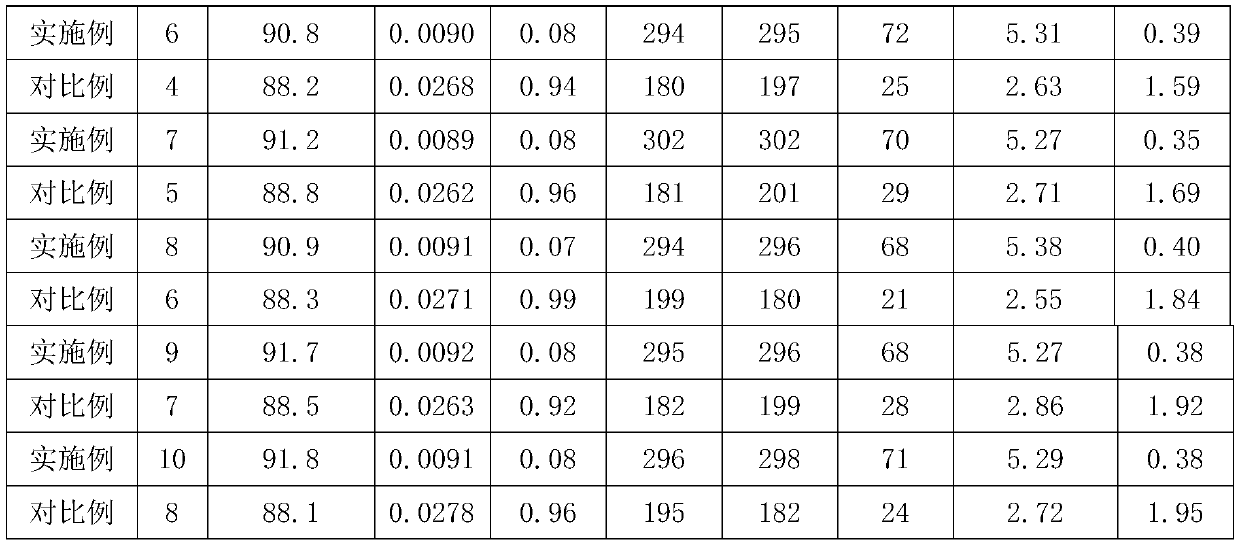

Examples

Embodiment 1

[0053] (1) Preparation of polyamic acid resin solution

[0054] In a nitrogen atmosphere, the temperature of the synthesis system is controlled at 15°C, and 0.628 kg of aromatic diamine 2,2'-bis(trifluoromethyl)- 4,4'-diaminobiphenyl (2,2'-TFDB) was stirred and dissolved. After 2,2'-TFDB was completely dissolved, 0.872 kg aromatic dianhydride 2,2-bis(3,4-dicarboxylic acid phenyl)hexafluoropropane dianhydride (6FDA), and stirred at 1500r / min, synthesized by polycondensation reaction for 24h to obtain solid content M=1.50kg, That is, a polyamic acid resin solution with a solid content ratio of 5 wt %;

[0055] (2) Preparation of colorless transparent gel slurry

[0056] Under the condition of controlling the temperature of the system at 20°C, add the flax fiber to the ionic liquid of N-alkyl-N-methylpyrrolidine bis(trifluoromethanesulfonyl)imide salt, and perform low-speed shear stirring at 100r / min for 2h, 800r / min high-speed shear stirring pretreatment for 5.5 hours, 28khz...

Embodiment 2

[0062] The difference between this example and Example 1 is that "the amount of flax fiber added is 0.3wt% of the solid content M in the polyamic acid resin solution described in step (1)".

Embodiment 3

[0064] The difference between this example and Example 1 is that "the amount of flax fiber added is 2.8wt% of the solid content M in the polyamic acid resin solution described in step (1)".

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com