Method for changing colour of colour-variable natural diamond and diamond obtained thereby

A diamond and natural technology, applied in the field of manufacturing gem-quality diamonds, can solve the problems of uneconomical and unreachable, and achieve the effect of increasing production and reducing cracking and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

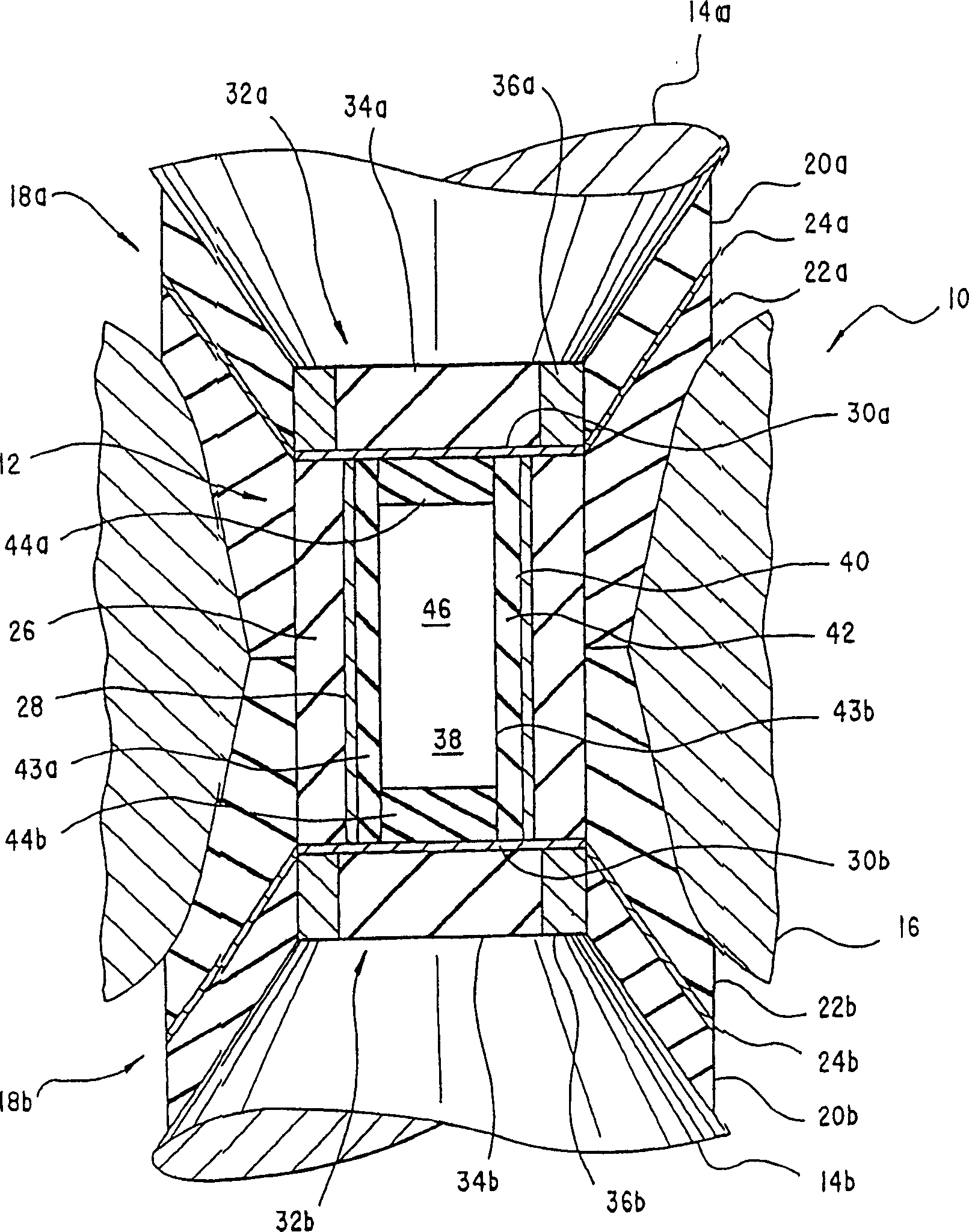

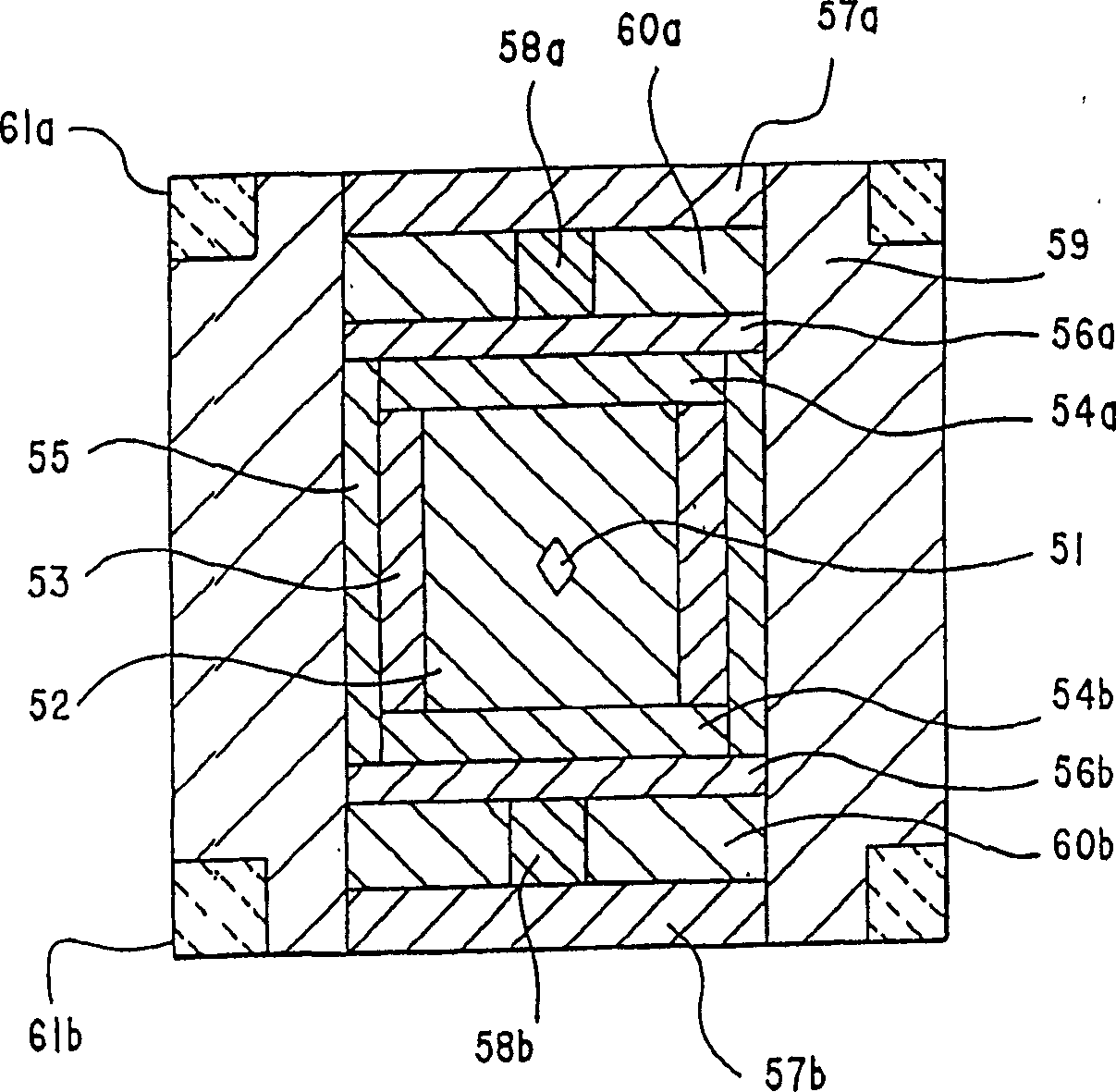

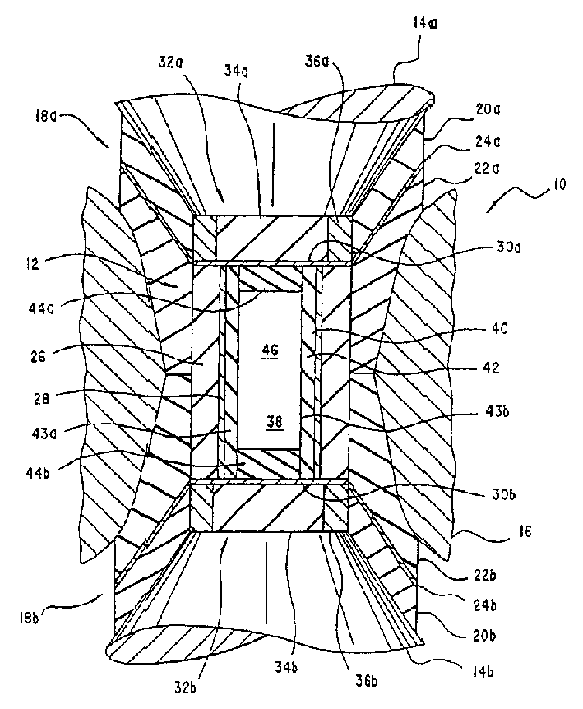

[0059] In this example, annealing of natural diamonds was performed using a belt device under high temperature and pressure conditions. The belt unit is capable of very high pressures (~60 kbar) and temperatures (~2600°C). Diamonds annealed in accordance with the present invention are described in the following examples using the reaction chamber of the configuration and operating conditions described below.

[0060] figure 2 The reaction chamber assembly is shown schematically. Pre-diced diamond crystals 51 are placed into cylindrical pellets made of high purity graphite or sodium chloride powder. The diamond crystal 51 has been pre-blocked using laser removal of material. Graphite is the recommended material because it does not melt during high temperature annealing. The dimensions of pellet 52 are as follows: 0.76 inches (19.3 mm) in diameter and 0.86 inches (21.8 mm) in height. The pellets 52 are formed by pressing graphite powder and diamond crystals 51 into a hydrau...

Embodiment I

[0064] A pre-blocked 3.49-carat grade IIa brown natural rough diamond was embedded in a graphite pellet pressed from high-purity graphite powder. The diamond was annealed at a pressure of ~60 kbar and a temperature of 2450°C for a holding time of for 6 minutes. The diamond crystal was recovered and visual inspection revealed that its color had changed to clear or colorless.

Embodiment II

[0066]A pre-blocked 3.29 ct class IIa polished brown natural diamond was embedded in a pellet compressed from high-purity sodium chloride powder, and the diamond was annealed at ~60 kbar pressure and 2500°C , hold time is 6 minutes. Visual inspection of the recovered diamond revealed that its color had changed to clear or colorless.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com