Farmland plastic film residue recycling and packaging combined operating machine

A combined working machine and residual film recovery technology, applied in agricultural machinery and implements, agriculture, collectors, etc., can solve the problems of increasing equipment and processes, high purchase cost, high labor intensity, etc., to achieve easy storage and transfer, saving Purchase cost, compact structure and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

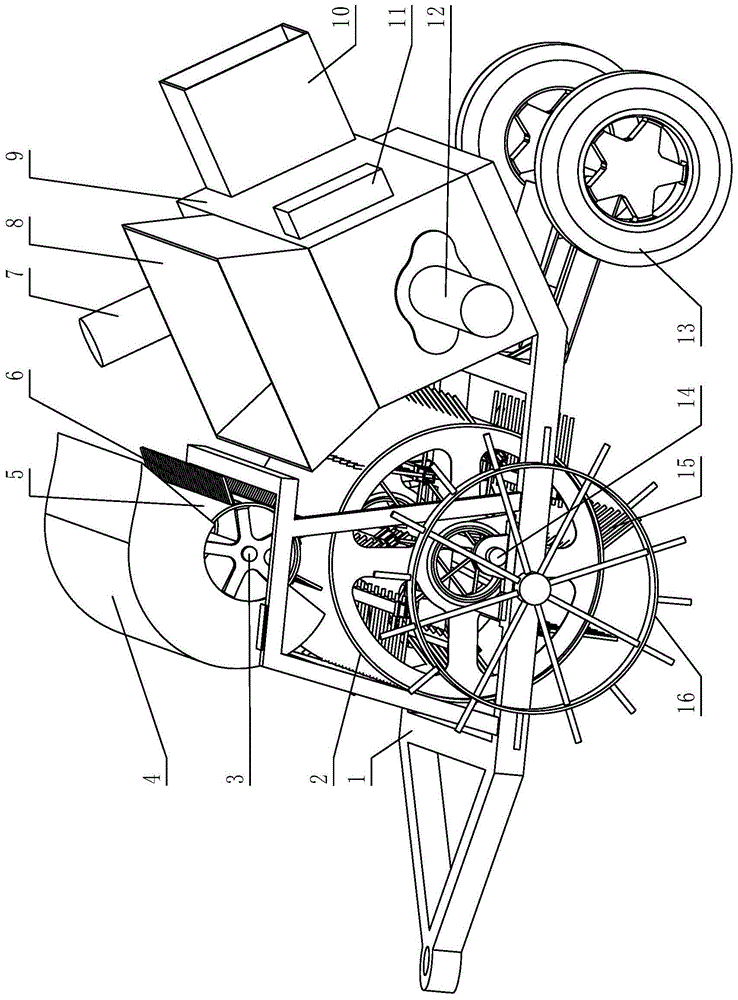

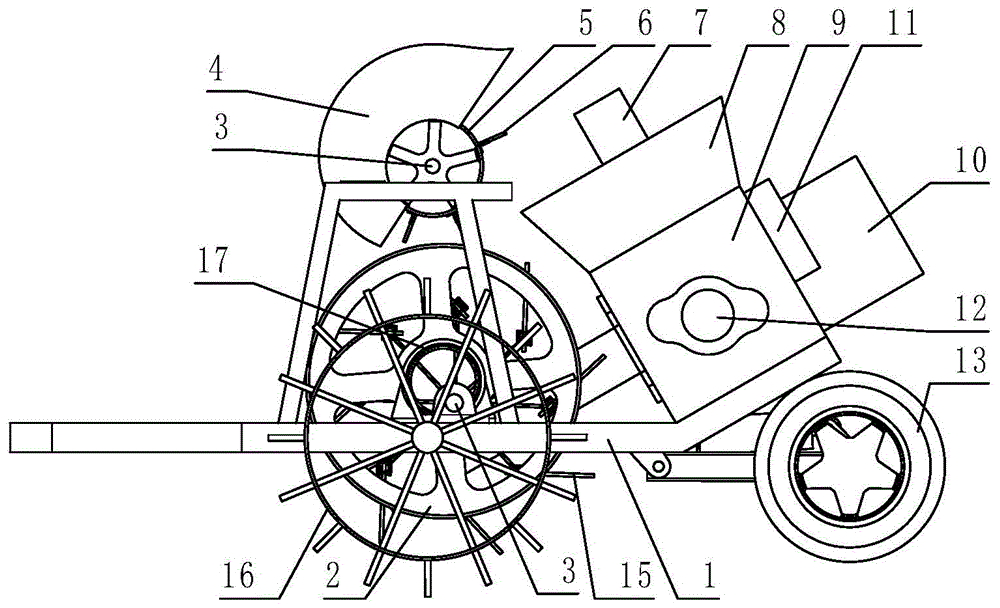

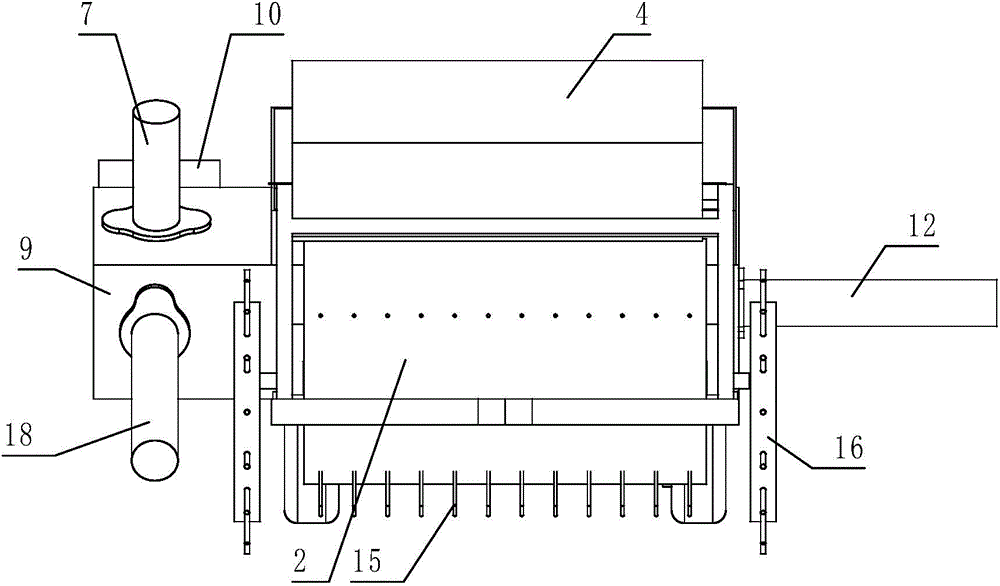

[0030] refer to figure 1 — Figure 12 , is a structural schematic diagram of an embodiment of the present invention, including a combined operation machine for recycling and packaging of residual film in farmland, including a frame 1, a transmission system, and traveling wheels 13, and a pick-up mechanism, a stripping mechanism, and a packing mechanism are arranged on the frame 1 , a ground wheel 16 is provided under the frame 1;

[0031] The pick-up mechanism is arranged below the frame 1, and the structure of the pick-up mechanism includes a drum 2, spring teeth 15, and a fixed frame 20 of spring teeth. The drum 2 is hollow cylindrical, and the cylinder wall is provided with strip-shaped openings 19. There are transmission rings 17 on both sides of the drum 2, the transmission rings are fixed to the outer ring of the bearing on the frame, and the transmission rings can be driven by the transmission chain to make the drum rotate; the elastic tooth fixed frame 20 includes the...

Embodiment 2

[0038] Compared with Embodiment 1, the difference of this embodiment is that a plurality of through holes 23 are arranged at intervals on the arc-shaped housing 4 of the stripping mechanism. The function of the through hole 23 is that during the stripping process, pebbles or other impurity particles brought up can be thrown out through the through hole 23 to play the role of preliminary impurity removal.

Embodiment 3

[0040] Compared with Embodiment 1, the difference of this embodiment is that a hydraulic cylinder control box 11 is provided on the packing box 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com