Massive tea pressing method

A technology of tea group and tea group, applied in the direction of tea treatment before extraction, etc., can solve the problems of difficulty in maintaining the original state, affecting the taste of the group tea, inconvenient operation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The pressing method of the present invention adopts electrical and hydraulic control of the lump-shaped tea pressing mold, which not only overcomes the problem of the taste of the lump-shaped tea being oxidized due to loose pressing, but also solves the problem of damage to the lump-shaped tea caused by difficult demoulding. The pressed lump tea of the invention has various and delicate shapes, and has the effect of complete color, fragrance and taste.

[0032] The lump tea pressing method of the present invention comprises the following steps: humidifying and softening the raw tea; pressing the moistened and softened raw tea with a lump tea pressing mold to form lump tea; taking out the lump tea from the lump tea pressing mould. Pressing the formed lump tea; drying and maintaining the shape of the taken out lump tea to obtain the finished lump tea.

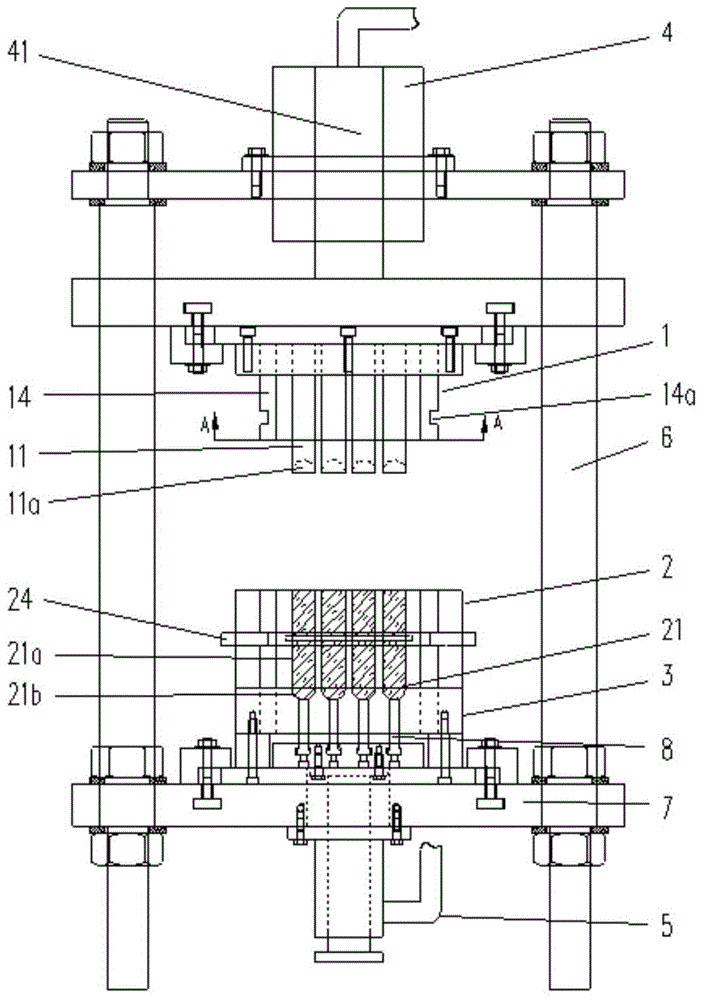

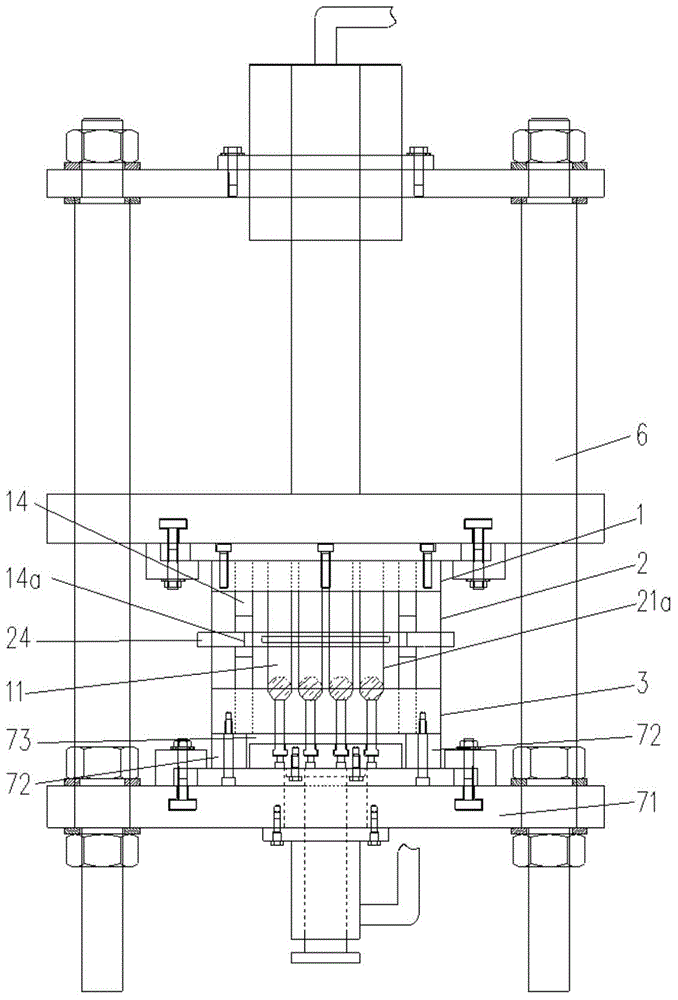

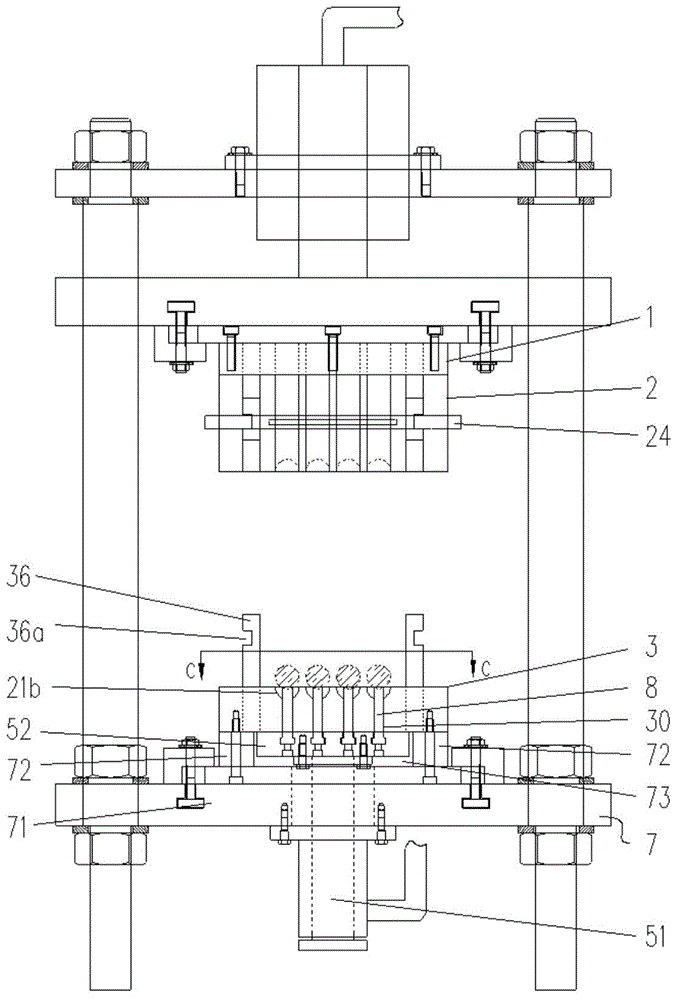

[0033] Among them, such as Figures 1 to 3 As shown, the group-shaped tea pressing mold of the present invention incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com