Vacuum pugging mixing device for laboratory

A vacuum mud refining and mixing device technology, which is applied in the field of material manufacturing and processing, can solve the problems of inability to mix dry materials, dust leakage, and poor visualization, and achieve the effect of compact structure, no dust leakage, and strong visualization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

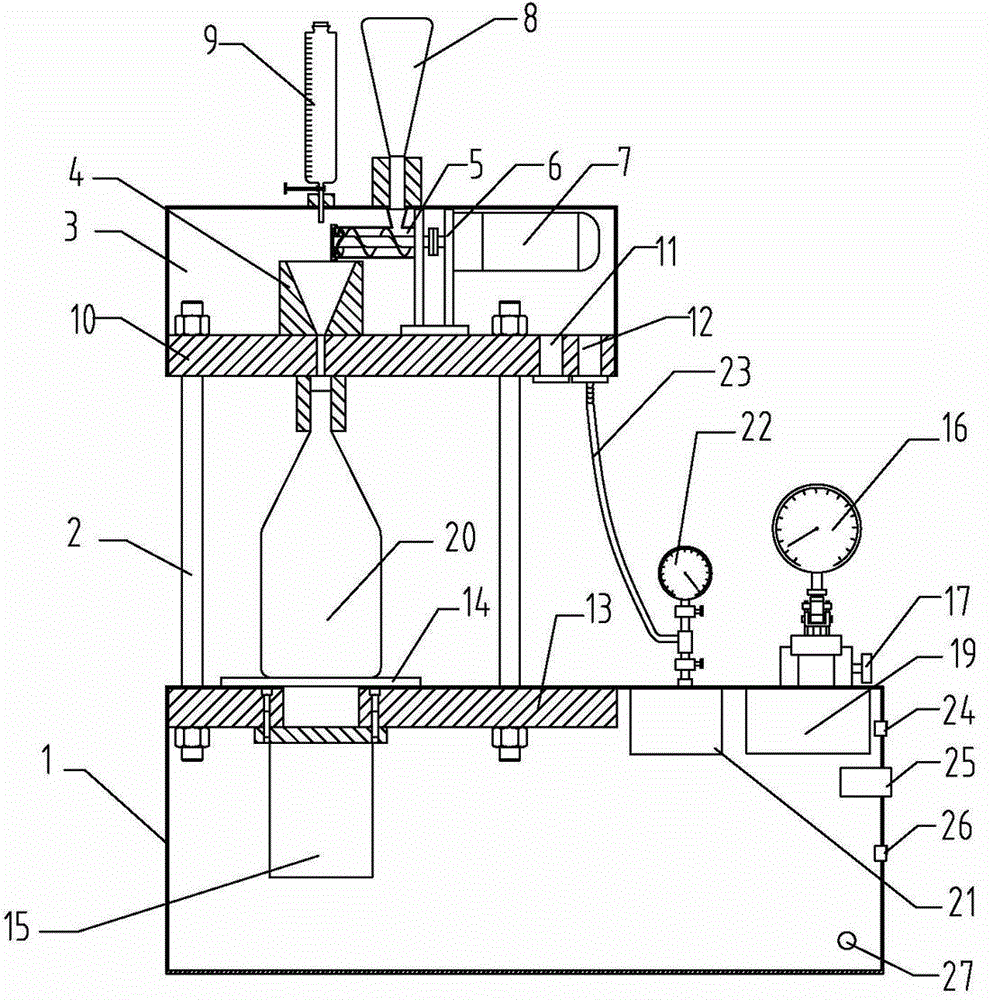

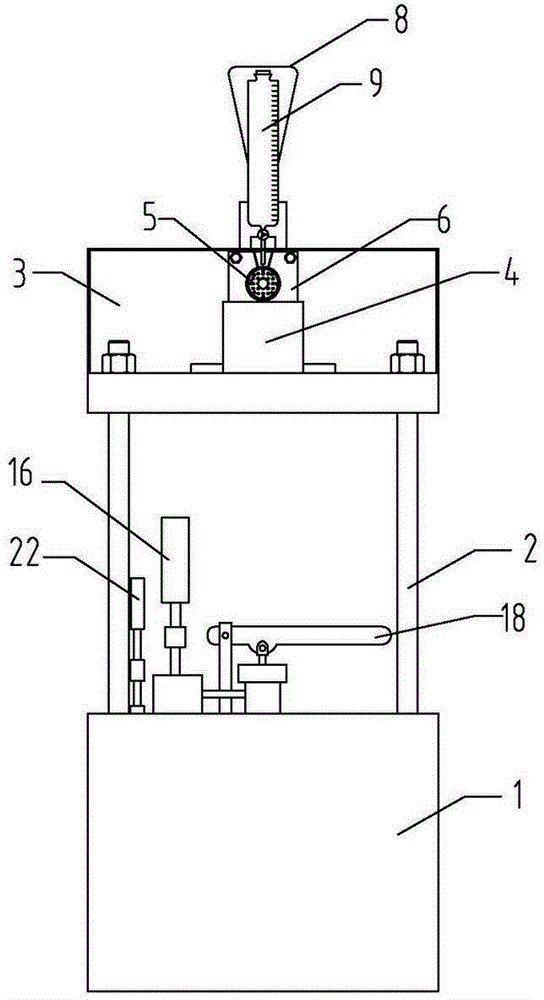

[0022] Embodiment 1: The present invention inserts the solid material feeder 8 filled with solid materials into the solid material feeding port during the vacuum refining mud mixing operation, and the rubber cylinder sleeve of the solid material feeder 8 is closely attached to the mud mixing material The upper glass surface of device box 3 guarantees airtightness, and the liquid material dispenser 9 that seals the rubber stopper cover tightly, is airtight, and fills liquid material is inserted in the liquid material feed port, and the liquid material dispenser 9 The rubber cylindrical disc is tightly attached to the upper glass surface of the mud mixing device box 3 to ensure airtightness (if necessary, the rubber cylindrical sleeve, the contact surface of the rubber cylindrical disc and the glass can be coated with vacuum sealing grease), and the material receiving device 20 is placed on the material receiving Press the supporting plate 14 of the material receiving device, put...

Embodiment 2

[0023]Embodiment 2: When the present invention carries out the dry material mixing operation under vacuum conditions, solid materials of different particle sizes or different types are contained in the solid material feeder 8, and the solid material feeder 8 is inserted into the solid material feed port , the rubber cylinder cover of solid material feeder 8 is closely attached to the upper glass surface of the mud mixing device box 3 to ensure airtightness, and the rotary valve of the liquid material feeder 9 filled with liquid material is closed to prevent the liquid material from leaking out. The rubber cylindrical disk of the liquid material dispenser 9 is tightly attached to the upper glass surface of the mud mixing device box 3 to ensure airtightness (if necessary, the rubber cylindrical sleeve, the contact between the rubber cylindrical disk and the glass can be coated with vacuum sealing grease), and the receiving material The material receiving device 20 is placed on th...

Embodiment 3

[0024] Embodiment 3: When the present invention carries out the mud mixing operation under normal pressure conditions, the solid material feeder 8 filled with solid material is inserted in the solid material feed port, and the rubber cylindrical sleeve of the solid material feeder 8 is compressed The upper glass surface of the mud mixing device box 3 guarantees sealing, and the liquid material dispenser 9 that seals the rubber stopper cover tightly, is airtight, and fills the liquid material is inserted in the liquid material feed port, and the liquid material dispenser The rubber cylindrical disk of the feeder 9 is pressed against the upper glass surface of the mud mixing device box 3 to ensure airtightness (if necessary, the rubber cylindrical sleeve, the contact between the rubber cylindrical disk and the glass can be coated with sealing grease), and the receiver 20 is placed On the material receiving device compression pallet 14, the material receiving port of the material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com