A simple and high-efficiency magnetic separation method for low-grade iron ore

A magnetic separation and high-efficiency technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of short separation belts of magnetic separation systems, fragile equipment, and difficulty in separating -75μm fine-grained minerals. To achieve the effect of large selection space, low operating cost, huge economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

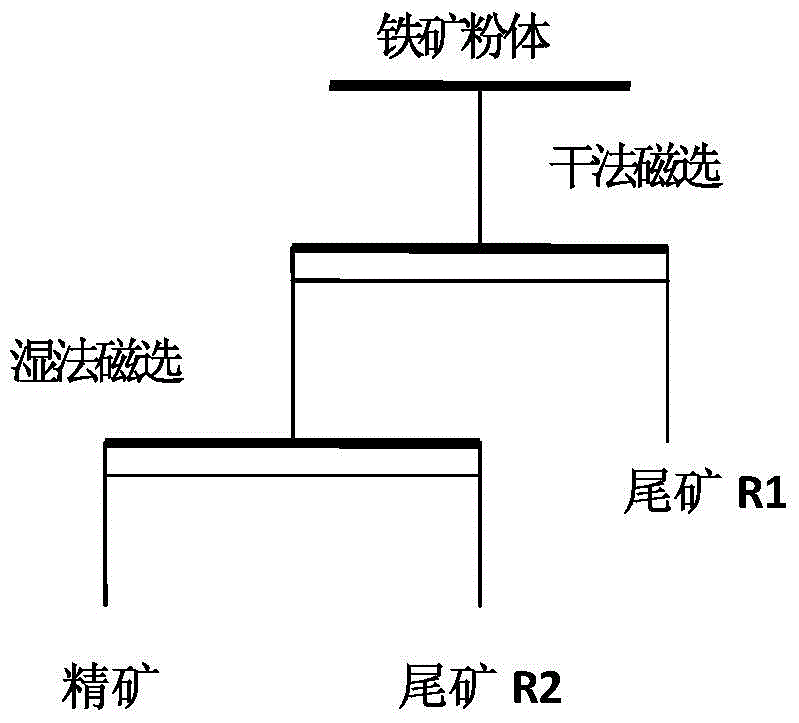

[0025] like figure 1 As shown, a simple and high-efficiency magnetic separation method for low-grade iron ore powder, the iron ore powder to be selected is 30.81% iron grade, including magnetic iron, false hematite, hematite, and the particle size is below 75 μm, accounting for 75% A certain low-grade iron ore.

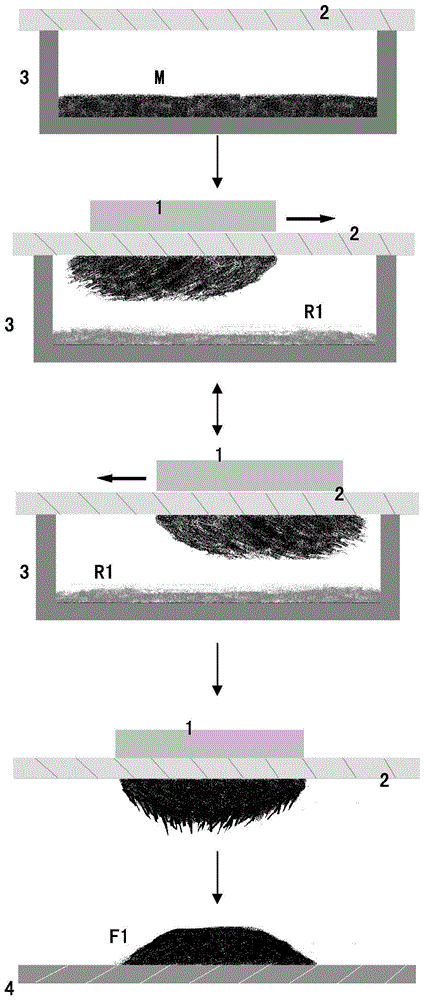

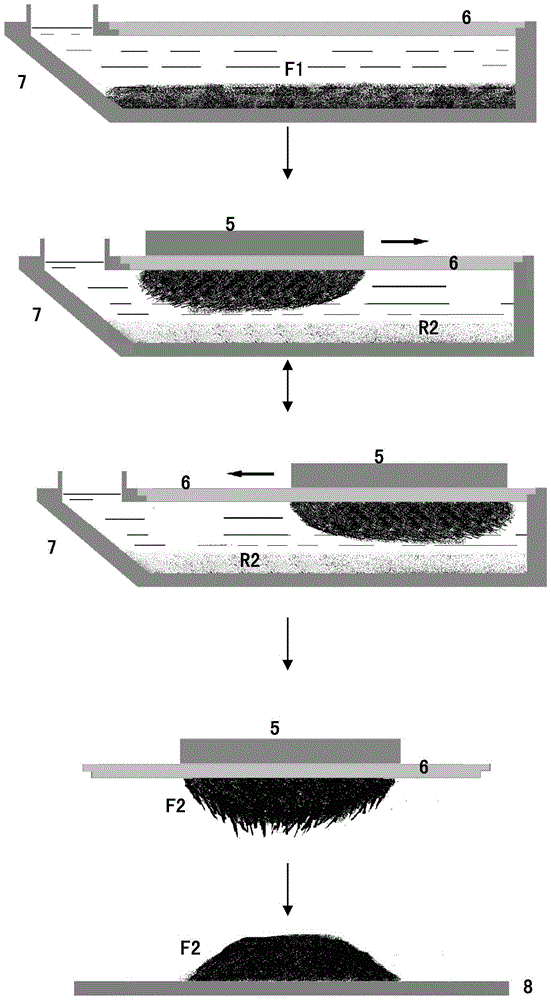

[0026] like figure 2 As shown, the tailings receiver 3 used in the dry magnetic separation is a wide-mouthed flat-bottomed glass container, the partition 2 is a glass plate, and the height of the separation zone is 18mm. The magnetic induction generated by the magnet 1 used in the dry magnetic separation on the other side of the partition 2 The strength is 210-320mT; the steps of dry magnetic separation are as follows: before separation, first place the iron ore powder M to be selected in the tailings receiver 3, and cover the tail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com