Electric precipitator and cathode ray thereof

A technology of electrostatic precipitator and cathode line, applied in electrode structure, electrode cleaning, external electrostatic separator, etc., can solve problems such as poor cleaning effect and complicated structure of spray device, improve cleaning effect, and avoid cleaning blind spots or dead corners , The effect of reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

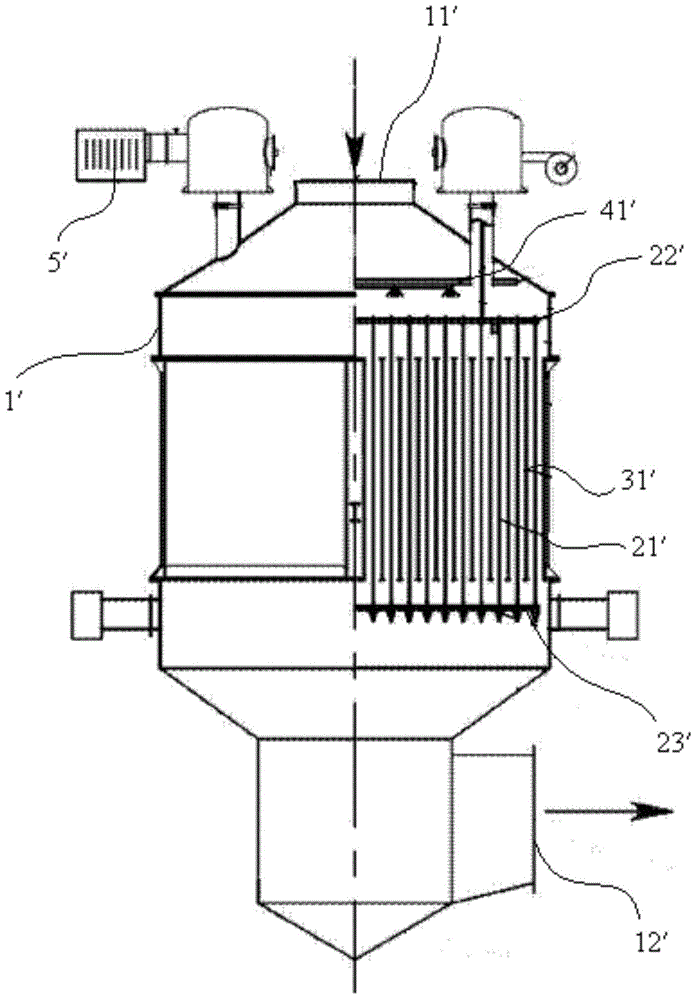

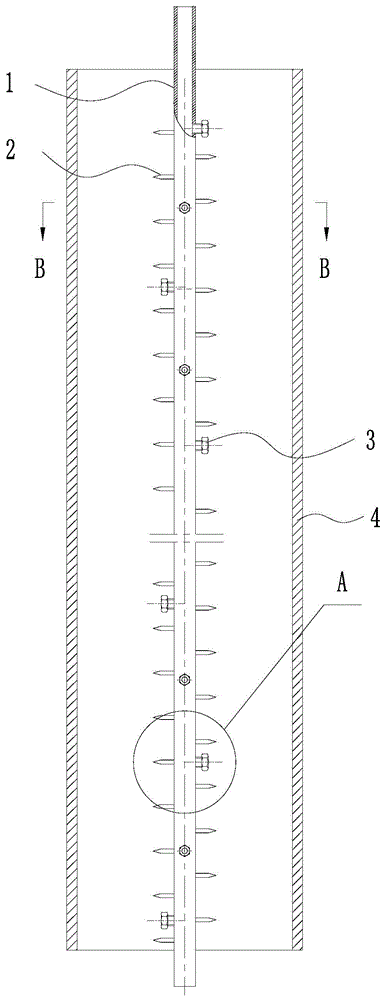

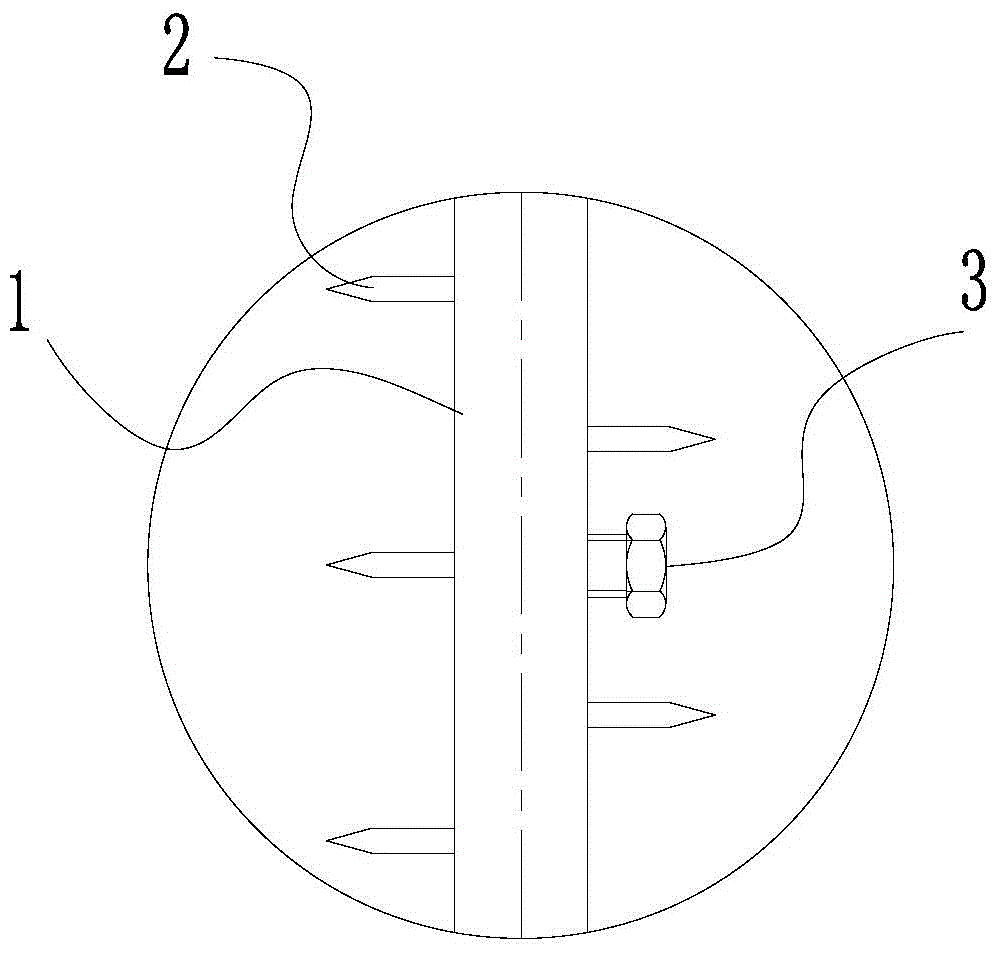

[0030] The core of the present invention is to provide a cathode line with a spraying function. Several nozzles are arranged on the metal tube of the cathode line, so that the nozzles are arranged above the original anode tube instead of being arranged inside the anode tube, which solves the problem of electric dust removal. During the operation of the electrostatic precipitator, the spray system cannot effectively clean the electric field, which strengthens the cleaning effect of the electric field and finally improves the dust removal efficiency of the electrostatic precipitator. On this basis, the present invention also provides an electrostatic precipitator comprising the cathode line.

[0031] The specific structure and working principle of the electrostatic precipitator and its cathode line provided by the present invention will now be described in detail with reference to the accompanying drawings.

[0032] See figure 1 and figure 2 ,in, figure 2 A schematic diagra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com