Equipment for coating wood board with oil paint

A technology for coating equipment and wood boards, which is applied to devices and coatings for coating liquids on the surface, which can solve the problems of orange peel, wrinkles, uneven coating amount, etc., to avoid wrinkles and orange peel, accurately The effect of paint coating amount and paint thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

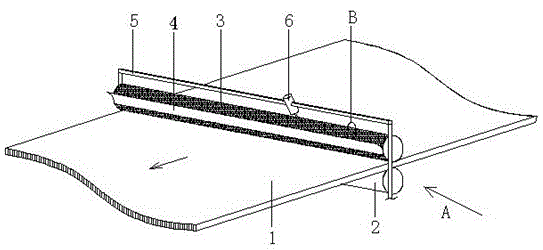

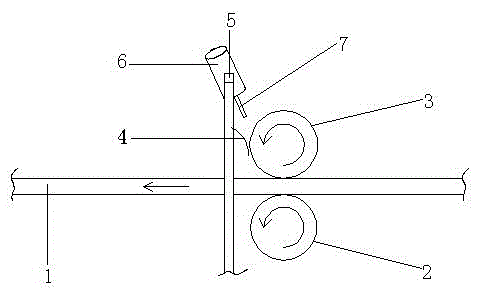

[0015] Such as figure 1 As shown, the present invention includes a lower roller 2 for conveying a wooden board 1 and an upper roller 3 above the lower roller 2 , the distance between the upper roller 3 and the lower roller 2 is not less than the thickness of the wooden board 1 .

[0016] A high-elastic steel sheet 4 inclined to the upper roller 3 is provided in front of the rotation direction of the upper roller 3. The upper surface of the steel sheet 4 is a parabolic surface, and the upper surface of the lower part of the steel sheet 4 is close to the surface of the upper roller 3. The closest distance is not less than Plank 1 needs the thickness of paint, and the distance between it decides according to the thickness of actual need coating paint.

[0017] In order to prevent the sharp edge of the steel sheet from scratching the surface of the upper roll, the steel sheet is a paraboloid, and its raised side is close to the upper roll. Through the scraping of the steel sheet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com