Two-component ratchet drive-by-wire glue gun

A two-component, ratchet technology, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems of affecting the performance of the adhesive, cost reduction, procurement and maintenance costs, etc. It is convenient for production and user use, and reduces production. and cost of use, the effect of increasing production and maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

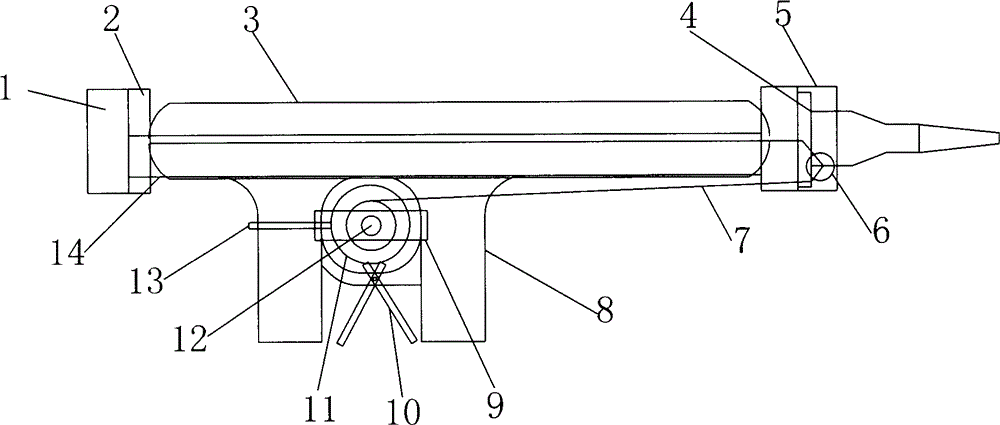

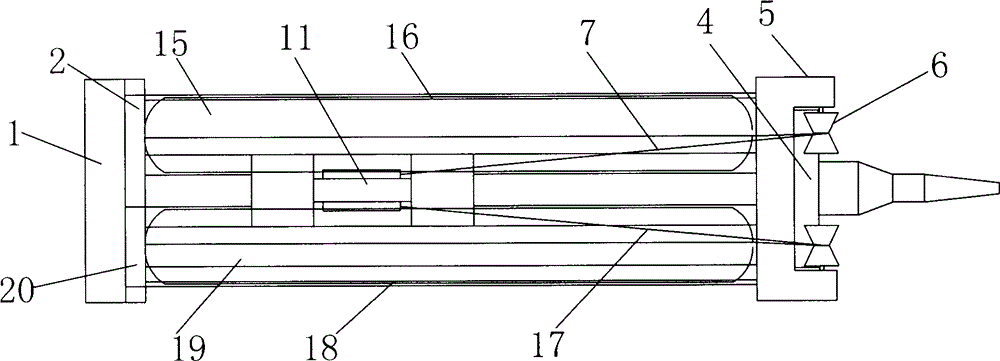

[0049] Embodiment 1: A two-component ratchet wire-controlled glue gun, including a front baffle 5 and a rear baffle 1, the front baffle 5 is provided with a glue nozzle 4 and a guide wheel 6, and the glue nozzle 4 includes a transition Glue nozzle 30 and glue mixing nozzle 31, described transition glue nozzle 30 comprises two independent glue outlet chambers 29, and glue mixing nozzle 31 is installed on the glue outlet of transition glue nozzle 30, and described front baffle 5 and rear baffle 1 is provided with a guide rail 14, the guide rail 14 includes a first guide rail 16 and a second guide rail 18, the first guide rail 16 and the second guide rail 18 are respectively a guide rail with a regular hexagonal section, the first A guide rail 16 surrounds itself to form a first glue-holding space 15, and a second guide rail 18 surrounds itself to form a second glue-holding space 19. Openings are arranged above the first glue-holding space 15 and the second glue-holding space 19. ...

Embodiment 2

[0050]Embodiment 2: A two-component ratchet wire-controlled glue gun, including a front baffle 5 and a rear baffle 1, the front baffle 5 is provided with a glue nozzle 4 and a guide wheel 6, and the glue nozzle 4 includes a transition Glue nozzle 30 and glue mixing nozzle 31, described transition glue nozzle 30 comprises two independent glue outlet chambers 29, and glue mixing nozzle 31 is installed on the glue outlet of transition glue nozzle 30, and described front baffle 5 and rear baffle 1 is provided with a guide rail 14, the guide rail 14 includes a first guide rail 16 and a second guide rail 18, the first guide rail 16 and the second guide rail 18 are respectively a guide rail with a regular hexagonal section, the first A guide rail 16 surrounds itself to form a first glue-holding space 15, and a second guide rail 18 surrounds itself to form a second glue-holding space 19. Openings are arranged above the first glue-holding space 15 and the second glue-holding space 19. T...

Embodiment 3

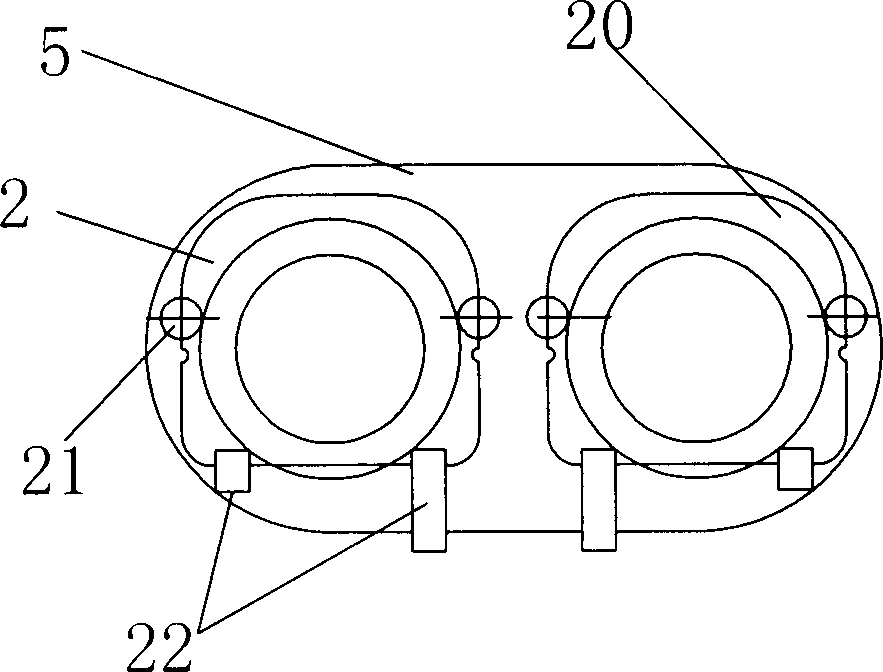

[0051] Embodiment 3: A two-component ratchet wire-controlled glue gun, including a front baffle 5 and a rear baffle 1, the front baffle 5 is provided with a glue nozzle 4 and a guide wheel 6, and the glue nozzle 4 includes a transition Glue nozzle 30 and glue mixing nozzle 31, described transition glue nozzle 30 comprises two independent glue outlet chambers 29, and glue mixing nozzle 31 is installed on the glue outlet of transition glue nozzle 30, and described front baffle 5 and rear baffle 1 is provided with guide rail 14, and described guide rail 14 comprises first guide rail 16 and second guide rail 18, and described first guide rail 16 and second guide rail 18 comprise two cylindrical guide rods 21 and two rectangular guide rods 22 respectively , the rectangular guide rod 22 is arranged below the cylindrical guide rod 21, the first guide rail 16 surrounds the first glue-holding space 15, the second guide rail 18 surrounds the second glue-holding space 19, and the first gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com