Production process of aluminum profile with 4D (Four-dimensional) wood grain surface

A production process and technology of aluminum profiles, applied in the process of producing decorative surface effects, devices for coating liquid on the surface, printing process, etc., can solve the problems of difficult to achieve decorative effects, poor wood grain effect, and uneven surface effects unevenness and other problems, to achieve the effect of aesthetic decoration and good wood grain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

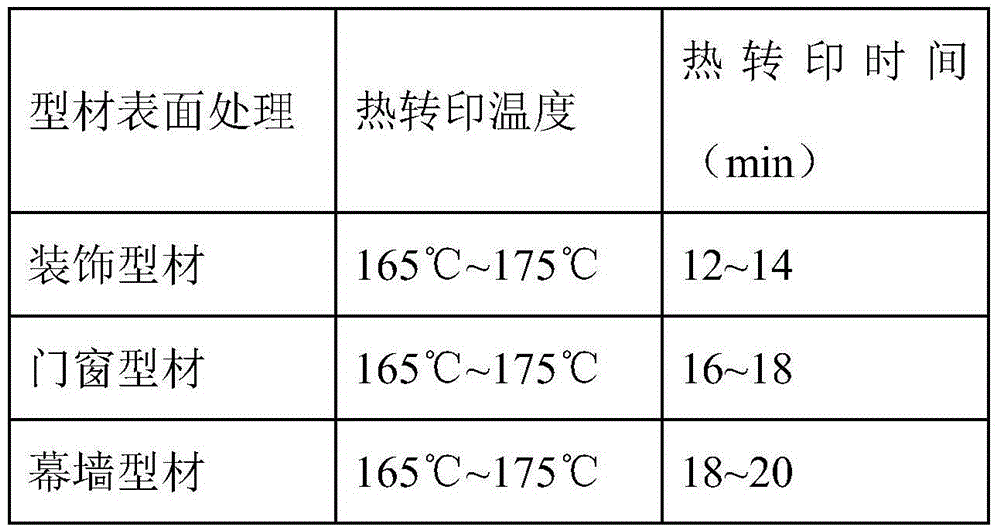

[0043] Preferred embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0044] The aluminum profile production process of a kind of 4D wood grain surface of the present invention comprises the following steps:

[0045] 1. Pretreatment

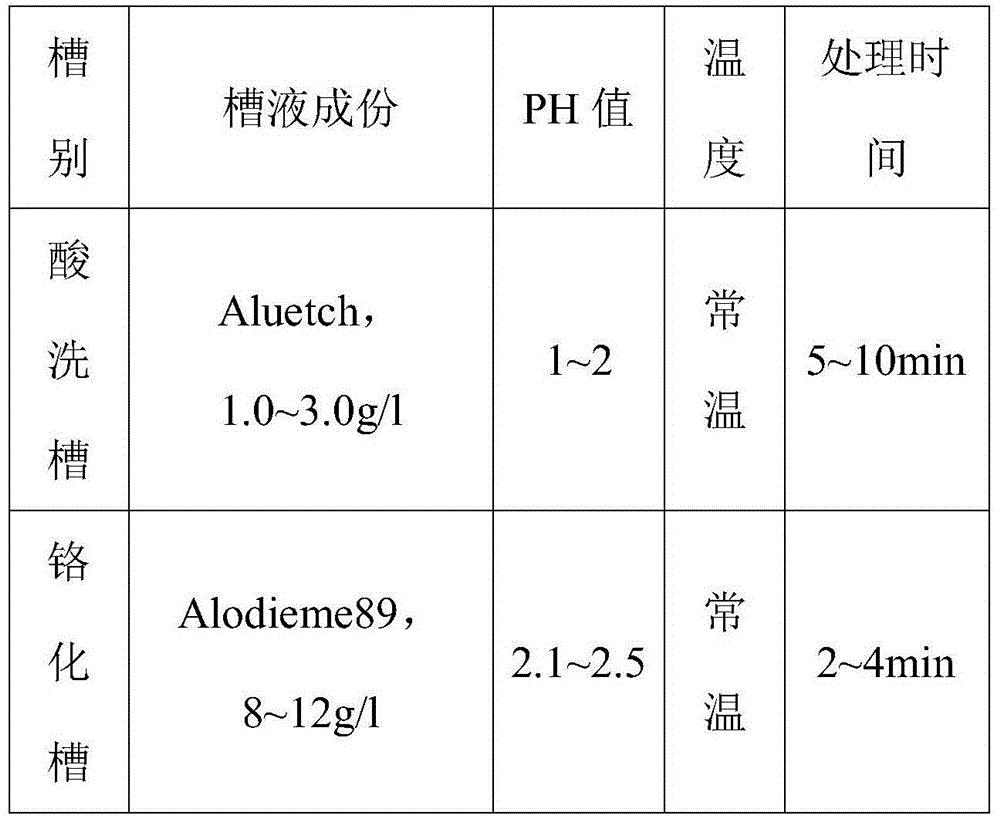

[0046] Inspection→pre-treatment put on the shelf→washing→pickling→washing→chromizing→washing→drying→off the shelf

[0047] 1 Profile pre-treatment and putting on the shelves: Only the profiles that have passed the inspection can be put on the shelves. When putting on the shelves, ensure that there is a gap between materials and materials, and overlapping is not allowed, so as to prevent the chromizing process from being unable to carry out chromizing treatment in an all-round way.

[0048] 2 Pickling: Pickling is to clean the oil stain on the surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com