Conveying device for aluminum balls

A technology of conveying device and sphere, applied in the field of conveying device of aluminum sphere, can solve the problems of low efficiency, high equipment cost, error, etc., and achieve the effect of avoiding error, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

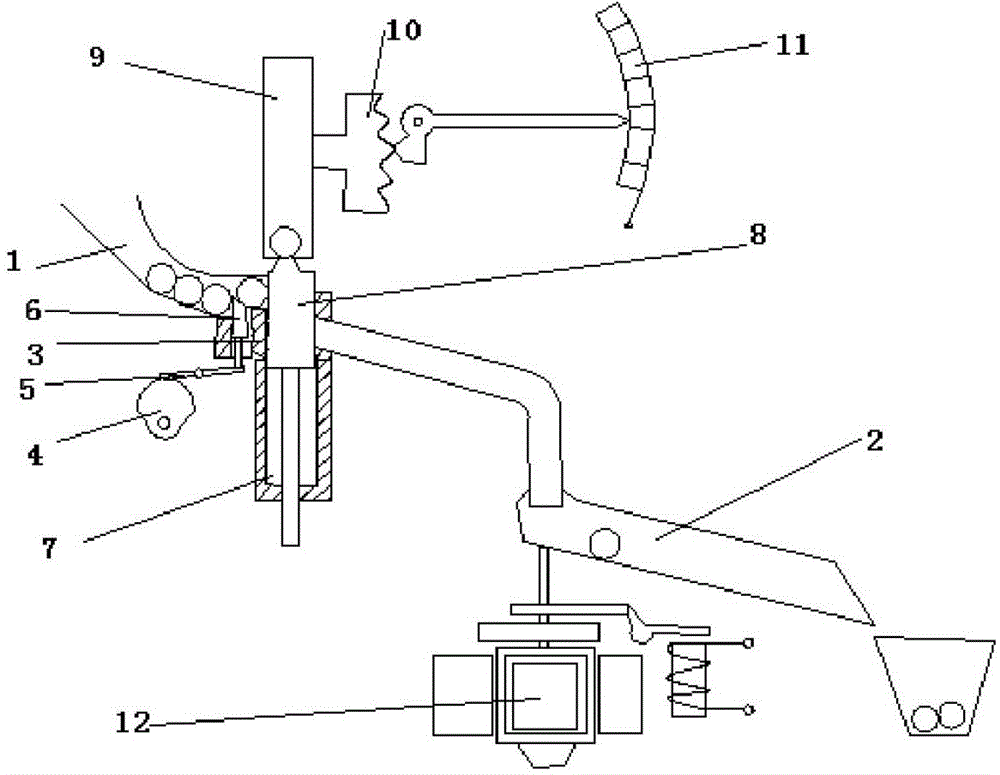

[0014] The reference signs in the description of the drawings are: input chute 1, output chute 2, protrusion 3, cam mechanism 4, swing rod 5, pusher 6, piston device 7, plunger 8, detection cylinder 9, diaphragm 10. Variable resistor 11, coil rotating device 12.

[0015] Such as figure 1 As shown, the technical solution provides a transmission device for aluminum spheres, including a rack separation device, a detection device and a transmission device. The transmission device includes an inclined input chute 1 and an output chute 2, and the output chute 2 is sleeved on the lower end of the input chute 1, and the output chute 2 can rotate around the input chute 1. The output end of the output chute 2 is provided with material storage boxes for depositing different types of spheroids. The input chute 1 is provided with a protrusion 3 for preventing the ball from sliding, and the distance between the upper surface of the protrusion 3 and the upper surface of the chute allows th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com