Copper wire drawing die and lubricating system thereof

A technology of wire drawing die and copper wire, applied in the direction of wire drawing die, etc., can solve problems such as poor lubrication effect, achieve the effect of improving wire drawing quality and efficiency, good lubrication effect, and improving lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

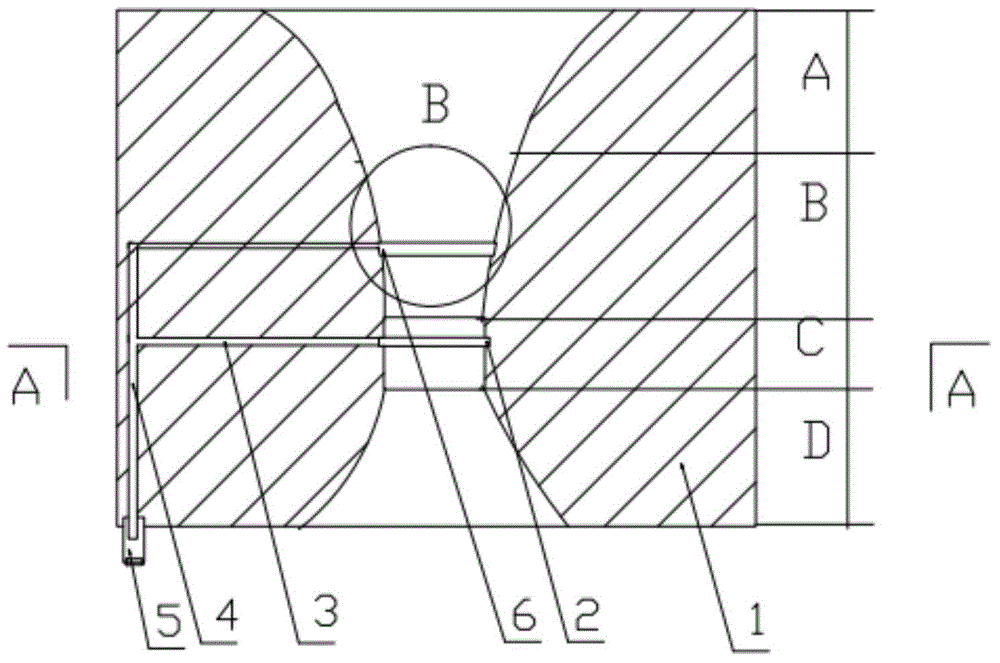

[0026] Such as Figure 1 to Figure 3 As shown, a copper wire drawing die includes a wire die body 1, and the wire die body 1 includes a wire passing hole, and the wire passing hole includes an inlet lubricating area A, a working area B, and a sizing area sequentially from the entrance to the exit. C and the outlet area D, a first annular groove 6 is provided on the inner wall of the working area B, and a flow channel communicating with the outside is provided on the first annular groove 6, and a hydraulic joint is provided at the outer end of the flow channel 5. The groove wall of the first annular groove 6 has a circular arc transition with the inner wall of the working area.

[0027] The fixed area diameter is provided with a second annular groove 2, and the second annular groove 2 communicates with the flow channel.

[0028] The depths of the first and second annular grooves are both 0.1-0.5 mm. The width of the annular groove is 1 to 5 mm

Embodiment 2

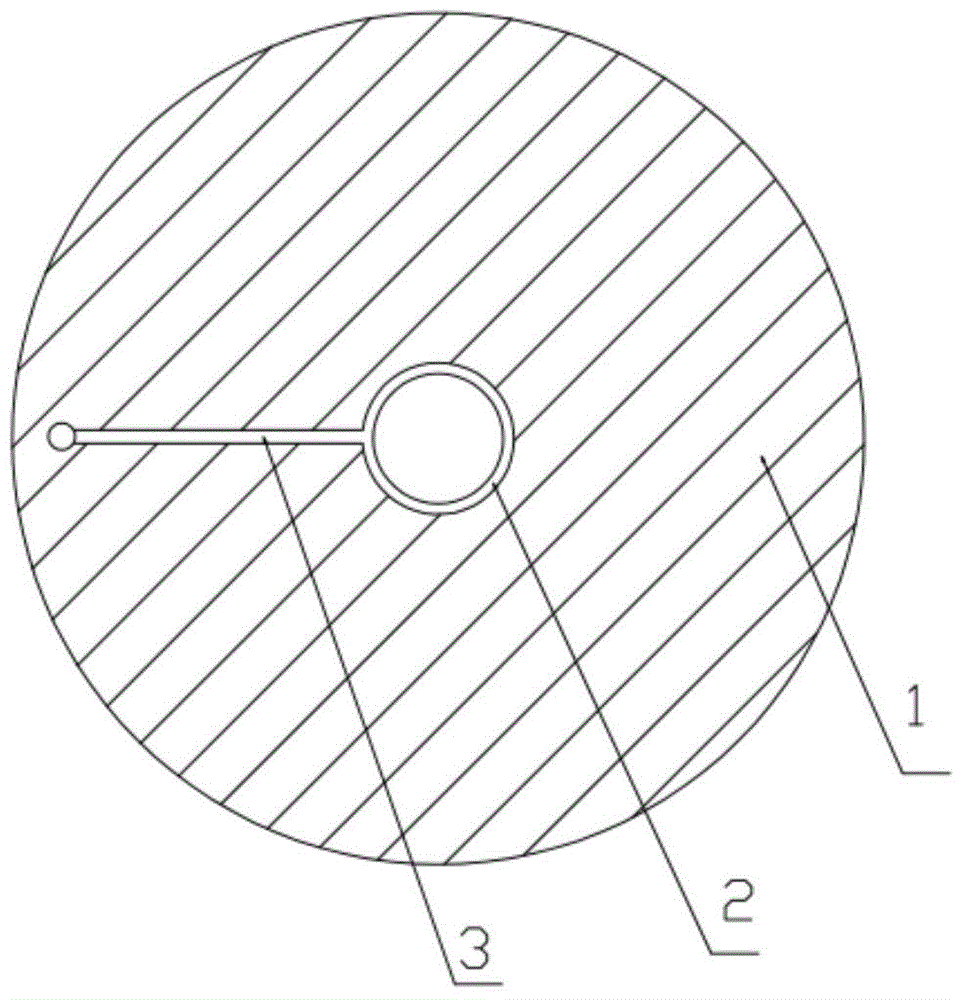

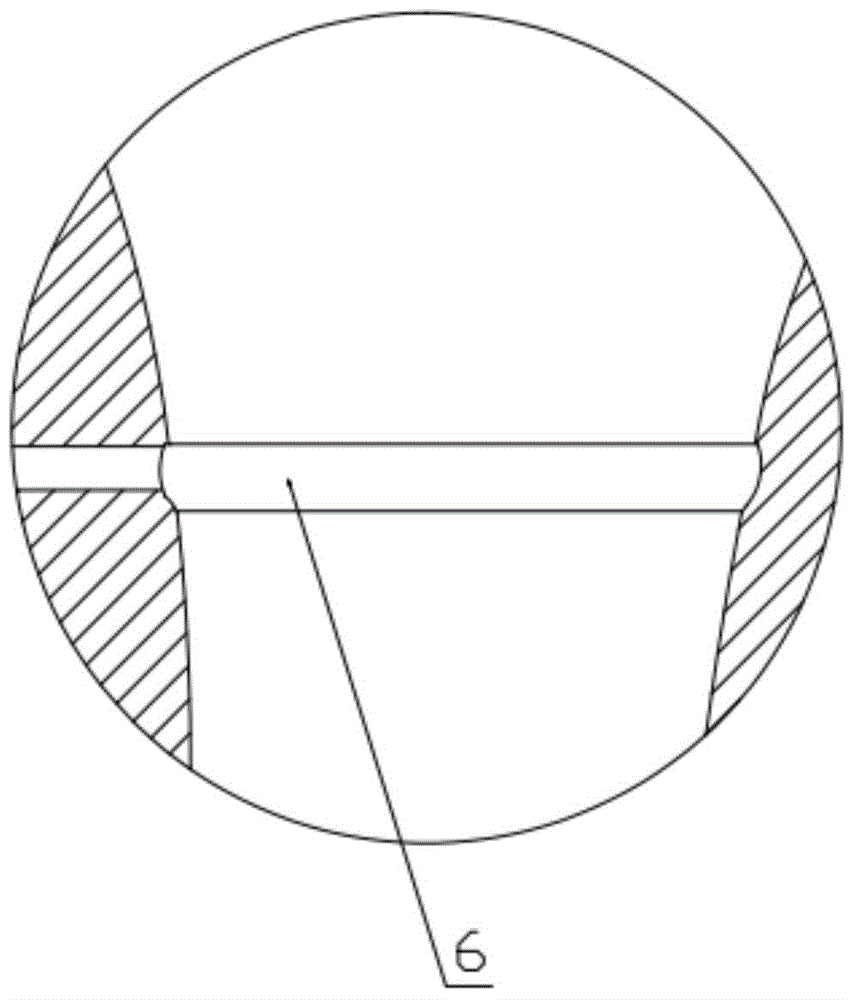

[0030] Such as Figure 4 and Figure 5 As shown, the wire mold body also includes an outer ring body 7, the flow channel includes a radial flow channel 3 and an axial flow channel 4, and the outlet of the axial flow channel 4 is provided with the hydraulic joint 5. With the structure of the outer ring body, the flow channel can be directly processed on the inner ring, and then the outer ring body can be fitted on the inner ring to facilitate the processing of the flow channel.

[0031] The rest of the structure of Embodiment 2 is the same as that of Embodiment 1, and will not be repeated here.

[0032] In specific use, the pressure applied to the annular groove is 0.1-10 MPa, which can better improve the lubrication effect. And should apply pressure while pulling.

[0033] Preferably, the pressure applied to the annular groove is 1-6 MPa.

[0034] Such as Figure 6 As shown, the present invention also provides a copper wire drawing die lubrication system, including the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com