Chemical preparation method of cobalt-iron alloy nanopowder

A technology of nano-alloy powder and cobalt iron, which is applied in the direction of nanotechnology, can solve the problems of difficult reduction preparation, etc., and achieve the effects of low preparation cost, mild reaction conditions and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

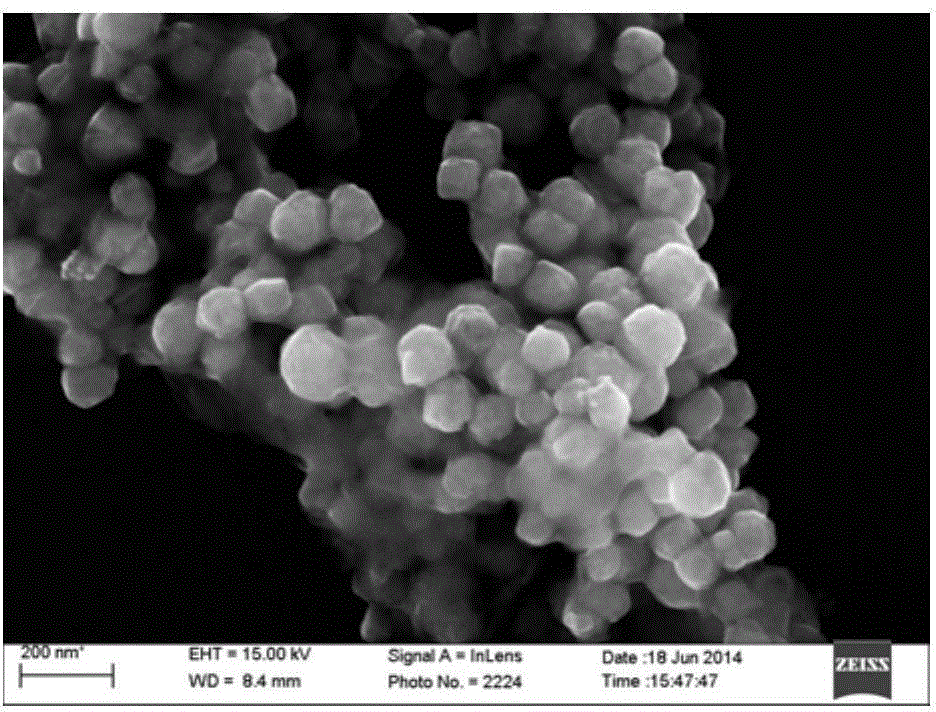

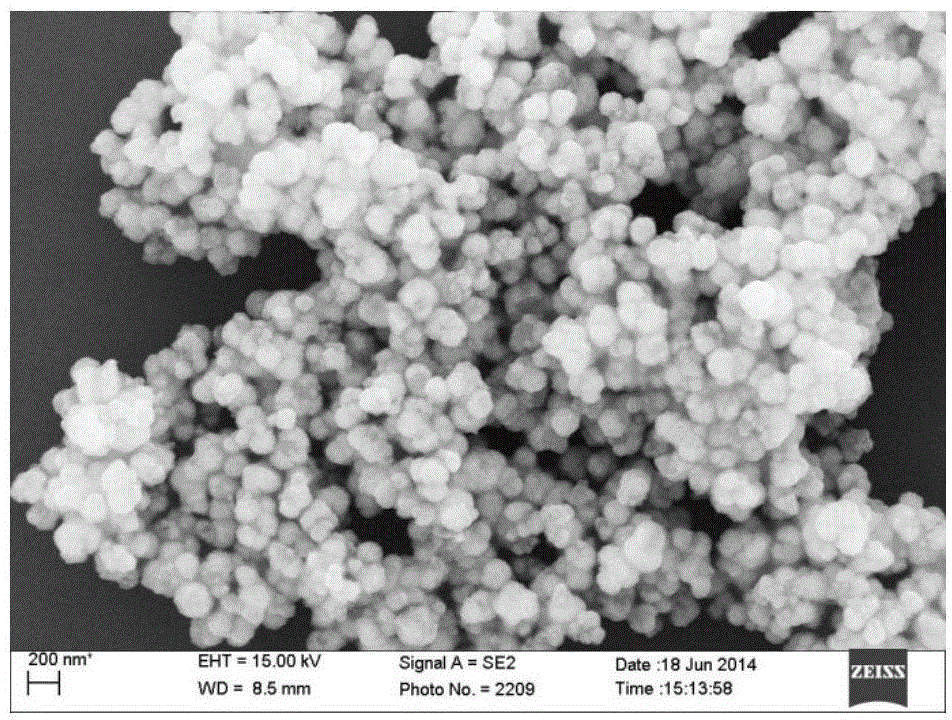

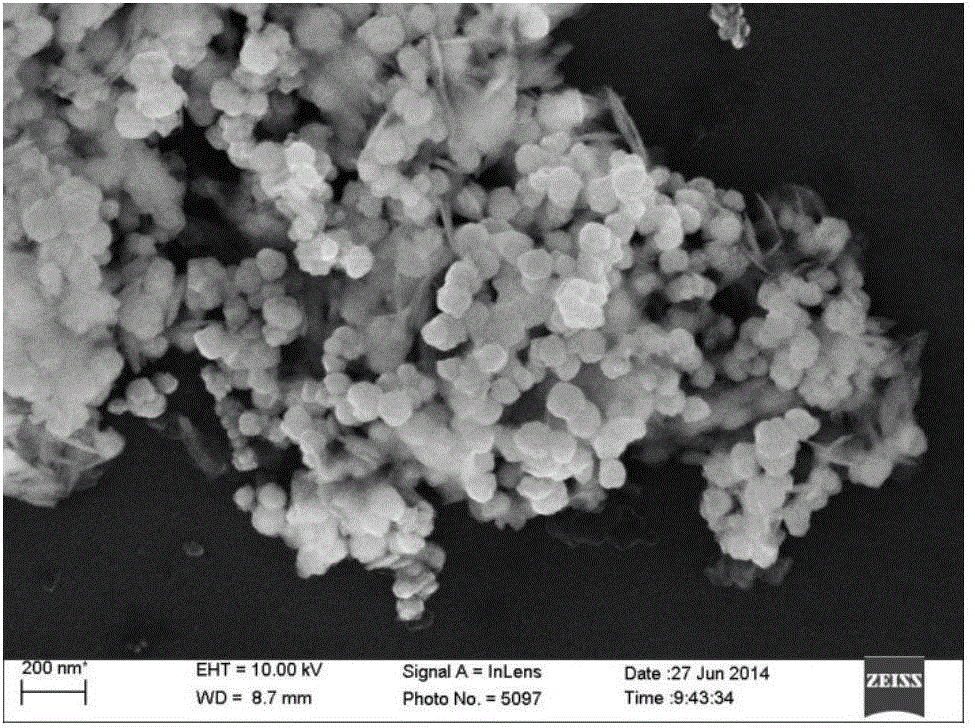

Image

Examples

Embodiment 1

[0031] 1. Preparation of reaction solution:

[0032] 1) Preparation of metal salt solution:

[0033] Use ethylene glycol as solvent to prepare solutions in the following proportions.

[0034] CoSO 4 0.04mol / L

[0035] FeSO 4 0.01mol / L

[0036] temperature 25°C

[0037] CTAB 0.70g / L

[0038] Stirring time 20 min

[0039] 2) Preparation of reducing agent solution ①:

[0040] Use ethylene glycol as solvent to prepare solutions in the following proportions.

[0041] KOH 0.20mol / L

[0042] Hydrazine hydrate 2.00 mL

[0043] temperature 25°C

[0044] Stirring time 20 min

[0045] 3) Preparation of reducing agent solution ②:

[0046] Use ethylene glycol as solvent to prepare solutions in the following proportions.

[0047] KOH 0.20mol / L

[0048] KBH 4 0.67g / L

[0049] temperature 25°C

[0050] Stirring time 20 min

[0051] 2. Preparation of cobalt-iron nanoparticles:

[0052] (1) Heat the solutions prepared by the above method to...

Embodiment 2

[0062] 1. Preparation of reaction solution:

[0063] 1) Preparation of metal salt solution:

[0064] Use ethylene glycol as solvent to prepare solutions in the following proportions.

[0065] CoSO 4 0.08mol / L

[0066] FeSO 4 0.01mol / L

[0067] temperature 25°C

[0068] PVP K30 0.70g / L

[0069] Stirring time 20 min

[0070] 2) Preparation of reducing agent solution ①:

[0071] Use ethylene glycol as solvent to prepare solutions in the following proportions.

[0072] KOH 0.80mol / L

[0073] Hydrazine hydrate 16.00mL

[0074] temperature 25°C

[0075] Stirring time 20 min

[0076] 3) Preparation of reducing agent solution ②:

[0077] Use ethylene glycol as solvent to prepare solutions in the following proportions.

[0078] KOH 0.80mol / L

[0079] KBH 4 0.67g / L

[0080] temperature 25°C

[0081] Stirring time 20 min

[0082] 2. Preparation of cobalt-iron nanoparticles:

[0083] (1) Heat the solution prepared by the above method ...

Embodiment 3

[0093] 1. Preparation of reaction solution:

[0094] 1) Preparation of metal salt solution:

[0095] Prepare solutions in the following ratios using water as solvent.

[0096] Co(NO 3 ) 2 0.04mol / L

[0097] Fe (NO 3 ) 3 0.01mol / L

[0098] temperature 25°C

[0099] PVP K30 0.70g / L

[0100] Stirring time 25 minutes

[0101] 2) Preparation of reducing agent solution ①:

[0102] Prepare solutions in the following ratios using water as solvent.

[0103] KOH 1.00mol / L

[0104] Hydrazine hydrate 2.00 mL

[0105] temperature 25°C

[0106] Stirring time 25 minutes

[0107] 2) Preparation of reducing agent solution ②:

[0108] Prepare solutions in the following ratios using water as solvent.

[0109] KOH 1.00mol / L

[0110] KBH 4 0.67g / L

[0111] temperature 25°C

[0112] Stirring time 25 minutes

[0113] 2. Preparation of cobalt-iron nanoparticles:

[0114] (1) Heat the solutions prepared by the above method to 70 °C respecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com