Laser cutter and flexible material roll cutting method

A laser cutting machine and flexible material technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of low work efficiency and high complexity, and achieve the effect of improving work efficiency and reducing production complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

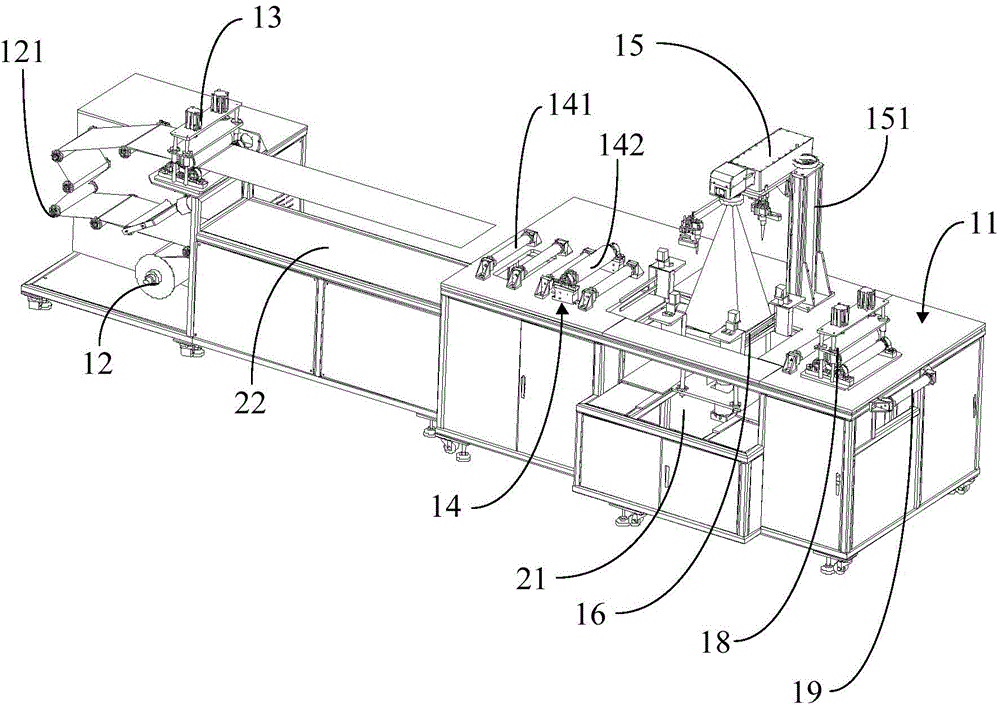

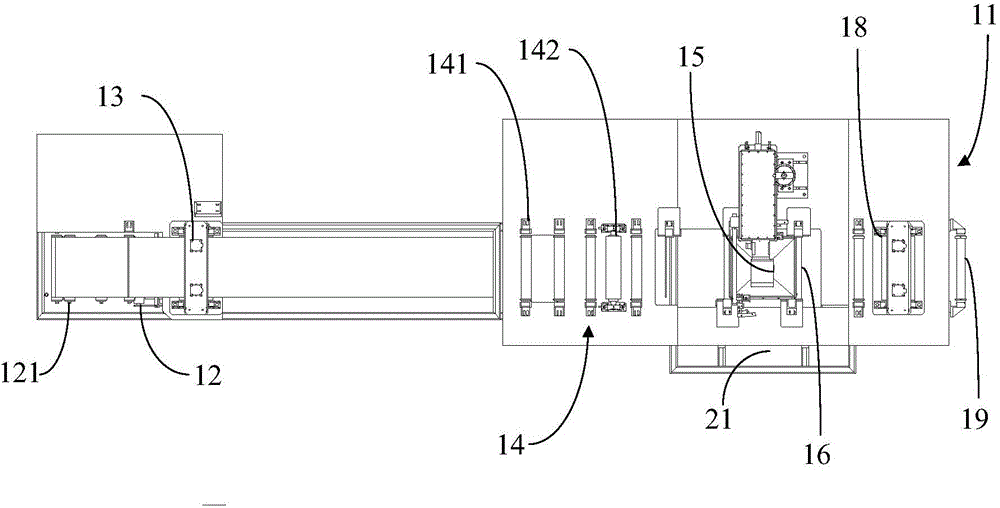

[0021] One embodiment of the present invention provides a laser cutting machine, including a base and a discharge mechanism, a first tensioning mechanism, a laser and a traction mechanism arranged on the base in sequence; the discharge mechanism is used to carry and release flexible materials roll; the first tensioning mechanism is used to tension the flexible material released by the feeding mechanism; the laser is used to cut the flexible material; a positioning mechanism is installed on the laser to position the processing line of the laser; the laser is below A cutting platform is provided for supporting the flexible material to be cut by the laser; a traction mechanism is used for pulling and tensioning the remaining material after the laser cuts the flexible material.

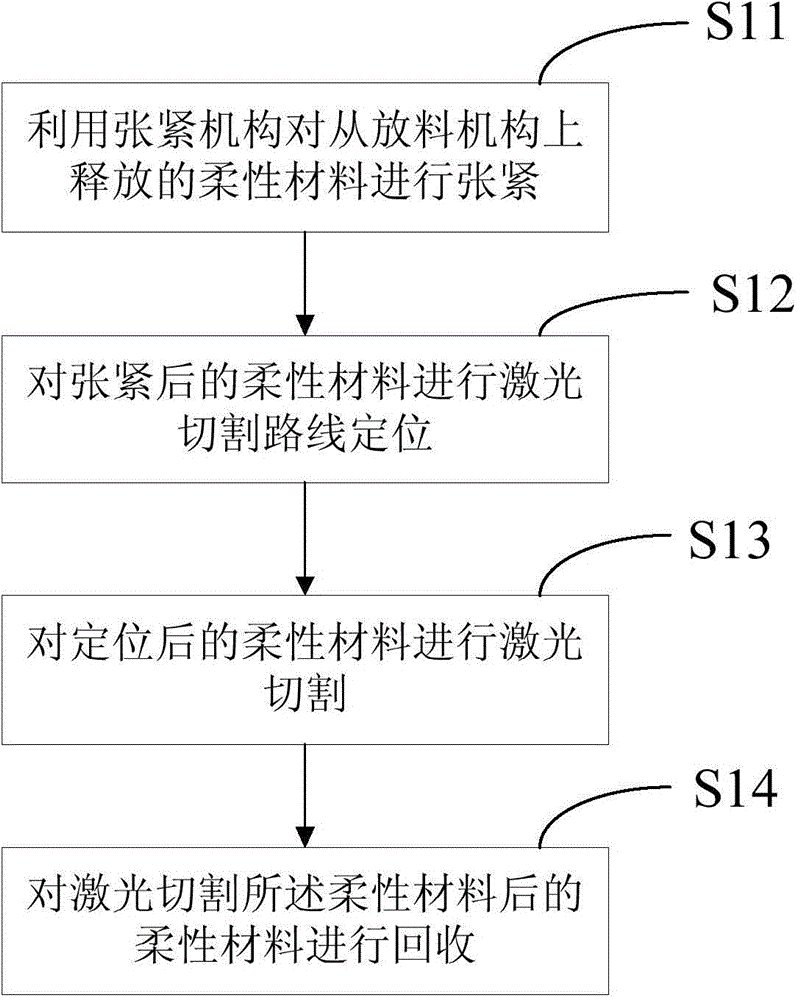

[0022] An embodiment of the present invention provides a flexible material roll cutting method, the cutting method comprising: using a tensioning mechanism to tension the flexible material released from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com