Automobile rear view mirror capable of resisting strong shock

A technology for automotive rearview mirrors and lenses, which is applied to vehicle parts, optical observation devices, transportation and packaging, etc., and can solve the problems of poor shock resistance, damage, and easy shattering of rearview mirrors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

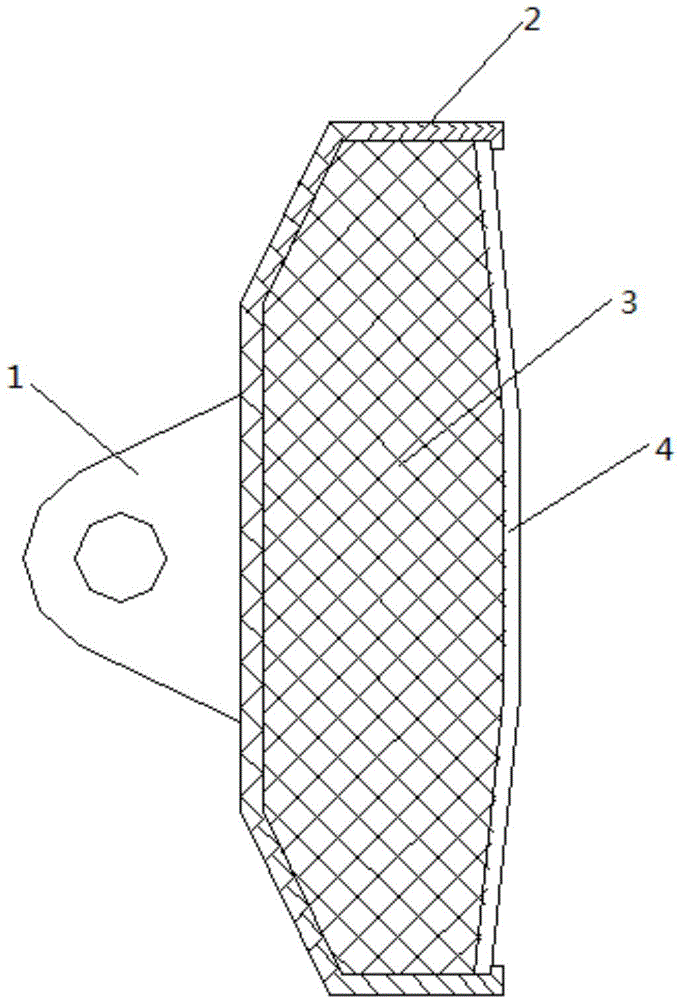

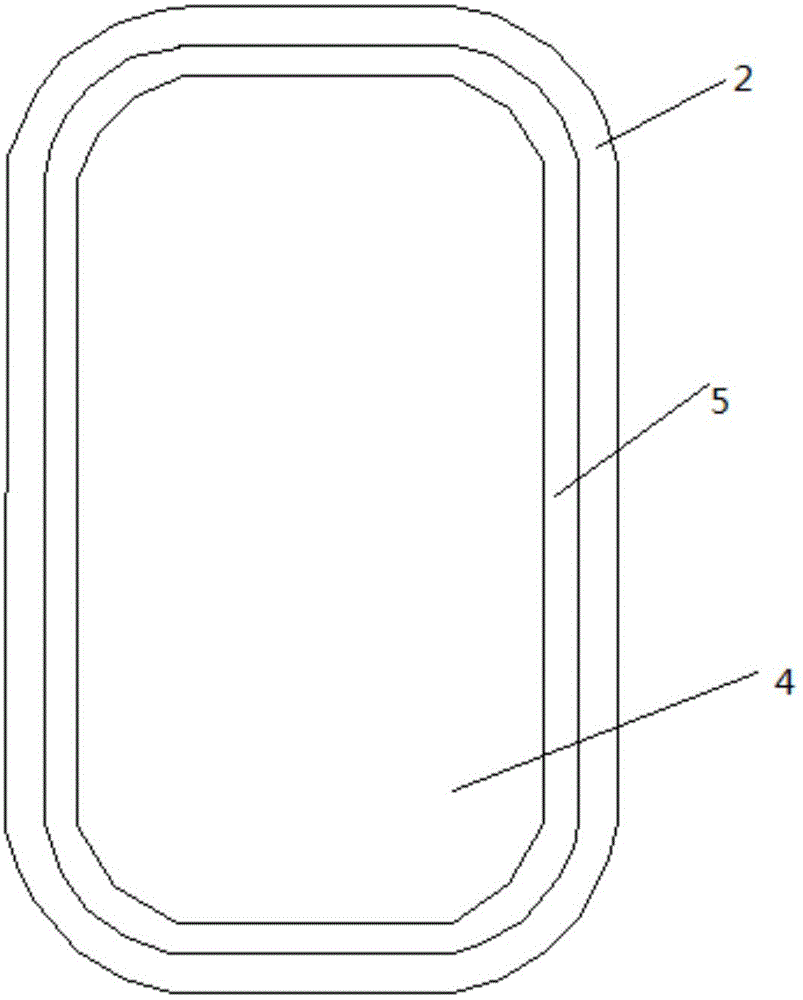

[0011] refer to figure 1 and figure 2 , an anti-strong shock automobile rearview mirror, including a frame 1, a lens 4 and a frame 2, a lens 4 is installed in front of the frame 1, a frame 2 is arranged around the lens 4, and an interlayer between the frame 1 and the lens 4 A filling material 3 for absorbing impact energy is provided in the middle, and an elastic material pad 5 is added at the outer edge of the rear of the lens around the frame 2 .

[0012] The lens 4 is a tempered glass lens.

[0013] The filling material 3 is polyurethane rubber.

[0014] Because there is polyurethane rubber, a filler material that absorbs impact energy, between the frame and the lens. Polyurethane rubber is a high-elastic polymer material. The force of the rearview mirror improves the impact resistance of the rearview mirror; an elastic material pad is added to the outer edge of the lens inside the frame to protect the lens and reduce the vibration damage of the lens.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com