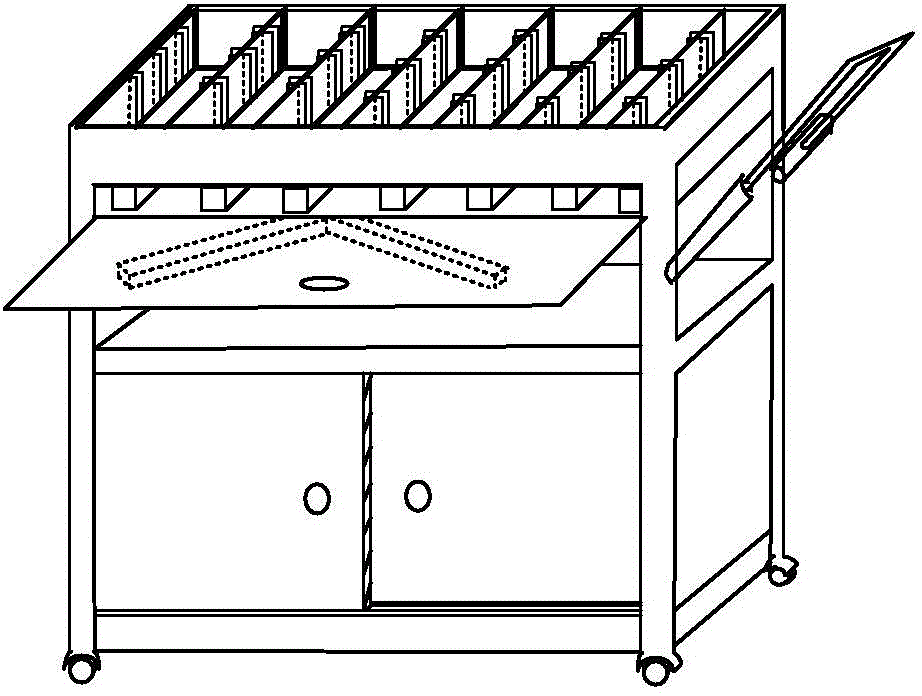

Intelligent tooling trolley

A trolley and tooling technology, applied in the direction of trolleys, multi-axis trolleys, trolley accessories, etc., can solve the problems that the bolts are not finely divided, easy to rust or rot, and prone to accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] Example: see figure 1 , a tool trolley, including the frame 1 of the car body and the wheels at the bottom of the car, and the handle connected to the frame. The trolley is divided into three layers. The bottom layer is an iron cabinet, the middle layer is a platform with edges, and the upper layer is a An iron box with an upper opening, and several vertical partitions that divide it into several storage areas; the vertical partitions on both sides of each storage area are equipped with limit bayonets at equal intervals. In the same holding area, a partition plate is added between the two limit bayonets opposite on both sides to further separate the holding area to obtain sub-areas; a weight sensor is installed at the bottom of each sub-area.

[0026] The wheel is a universal wheel, and a locking device is also arranged on it.

[0027] There is an opening on the upper side of the iron cabinet, and the side opening covers the cabinet door. The cabinet door includes a le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com