Full-automatic air valve inserting machine

A fully automatic valve technology, applied in the direction of single object, transportation and packaging, packaging, etc., can solve the problems of valve falling and ground collision, loss of post personnel, high labor intensity, etc., to avoid collision, work well, grasp Take and Slot Accurate Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

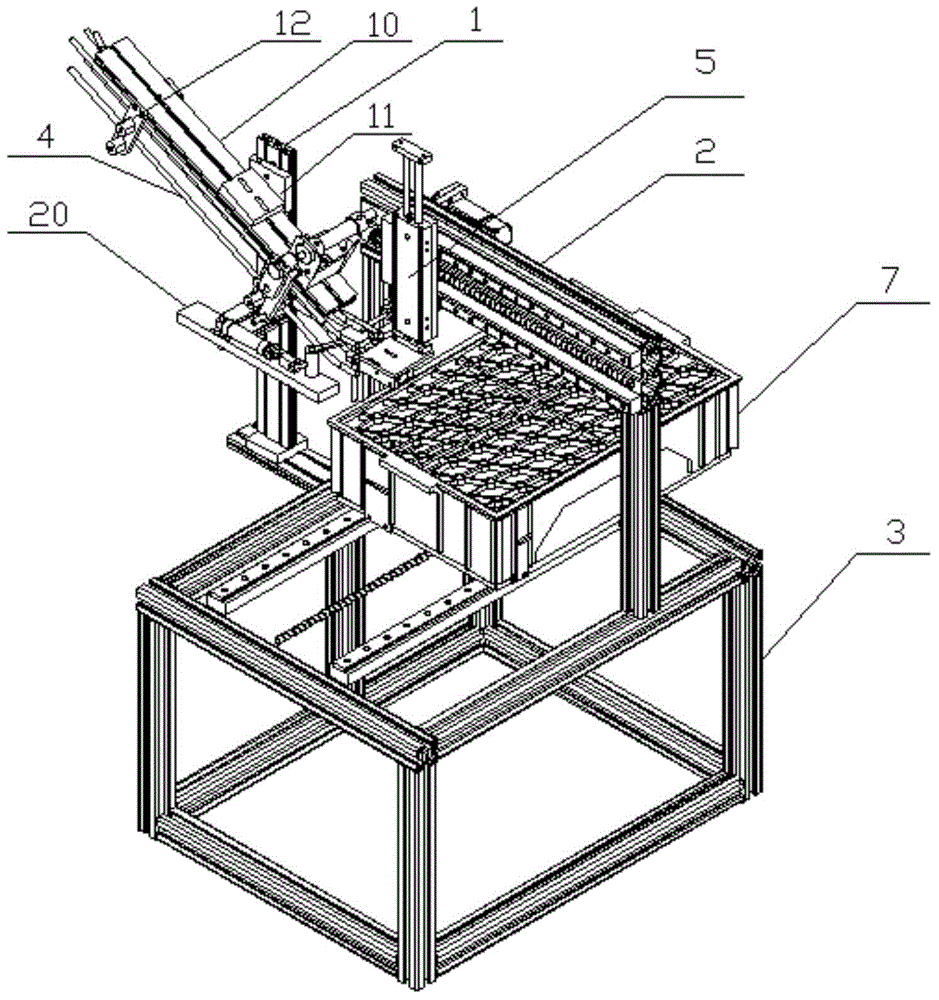

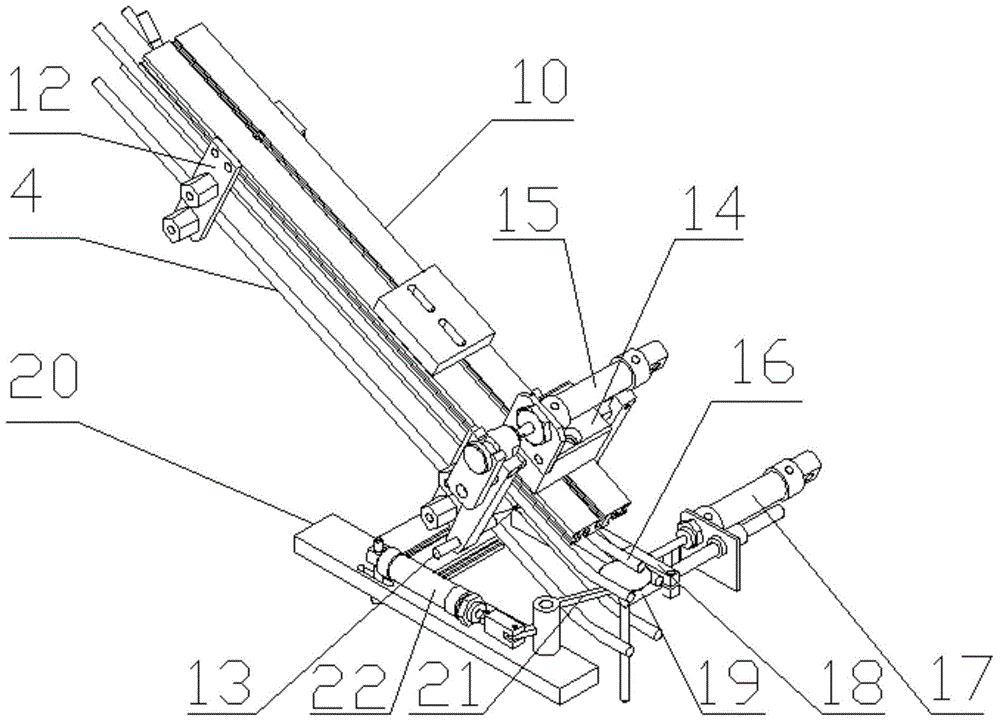

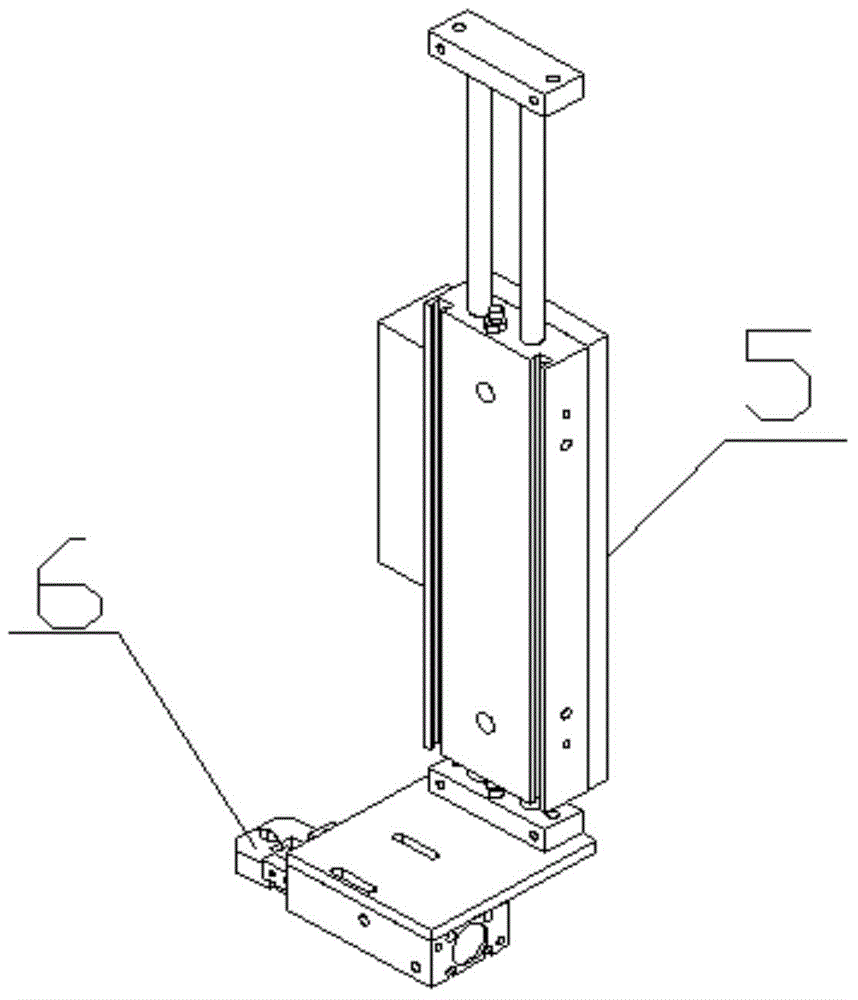

[0020] A fully automatic valve inserting machine, including a frame, a feeding system, a grabbing system, and a material receiving system. The base frame 3 used in the system, wherein the L-shaped bracket 1 is fixed on one side of the base frame 3, and the door-shaped bracket 2 is fixed on the upper end surface of the base frame 3; The material distributing mechanism in the middle section of the channel and the precise positioning mechanism arranged at the bottom of the inclined slideway. The inclined slideway includes two groups of sliding rods 4 arranged in parallel up and down. The distance between the two sliding rods 4 at the upper end is greater than that of the air valve. The diameter of the rod portion is less than the diameter of the valve head, and all slide rods 4 are gradually and smoothly transitioned to level by inclination at the bottom end.

[0021] Specific examples, such as Figure 1 to Figure 4 As shown, the valve head is placed between the two slide bars 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com