Canned product weighing and filling device

A filling device and weighing technology, used in packaging, packaging protection, transportation and packaging, etc., can solve problems affecting product packaging quality and other issues, and achieve the effect of ensuring filling accuracy and high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

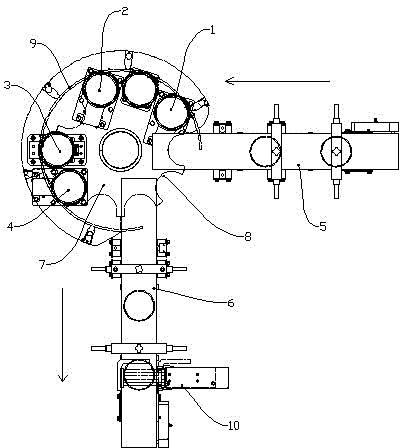

[0009] As shown in the figure, the can product weighing filling device includes a conveying device that can drive the packaging cans to move sequentially, and the empty can weighing station 1, which can weigh the empty cans, is arranged in sequence on the conveying stroke of the conveying device The rough weighing station that can quickly fill the material to the required weight and weigh it 2, the fine filling station that can fill the material to the required weight 3, and the finished product weighing station that can weigh the filled tank product 4.

[0010] The conveying device includes a straight-line conveying net chain machine 5 for tanks, a net chain machine 6 for straight-line transporting out of tanks, and a driving edge of the cans connected between the net chain machine 5 for tanks and the net chain machine for discharging tanks 6. The dial 7 that moves along the arc-shaped conveying route; the outer circumference of the dial 7 is distributed with arc-shaped groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com