vertical lifting mechanism

A technology of vertical lifting mechanism and lifting mechanism, which is applied in the field of handling vehicles, can solve the problems of high vehicle cost, oil leakage, high hydraulic system use and maintenance costs, etc., and achieve the effect of simple structure and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. However, the scope of protection of the present invention is not limited to the following examples, that is, any simple equivalent changes and modifications made based on the patent scope of the present invention and the content of the description are still within the scope of the patent of the present invention.

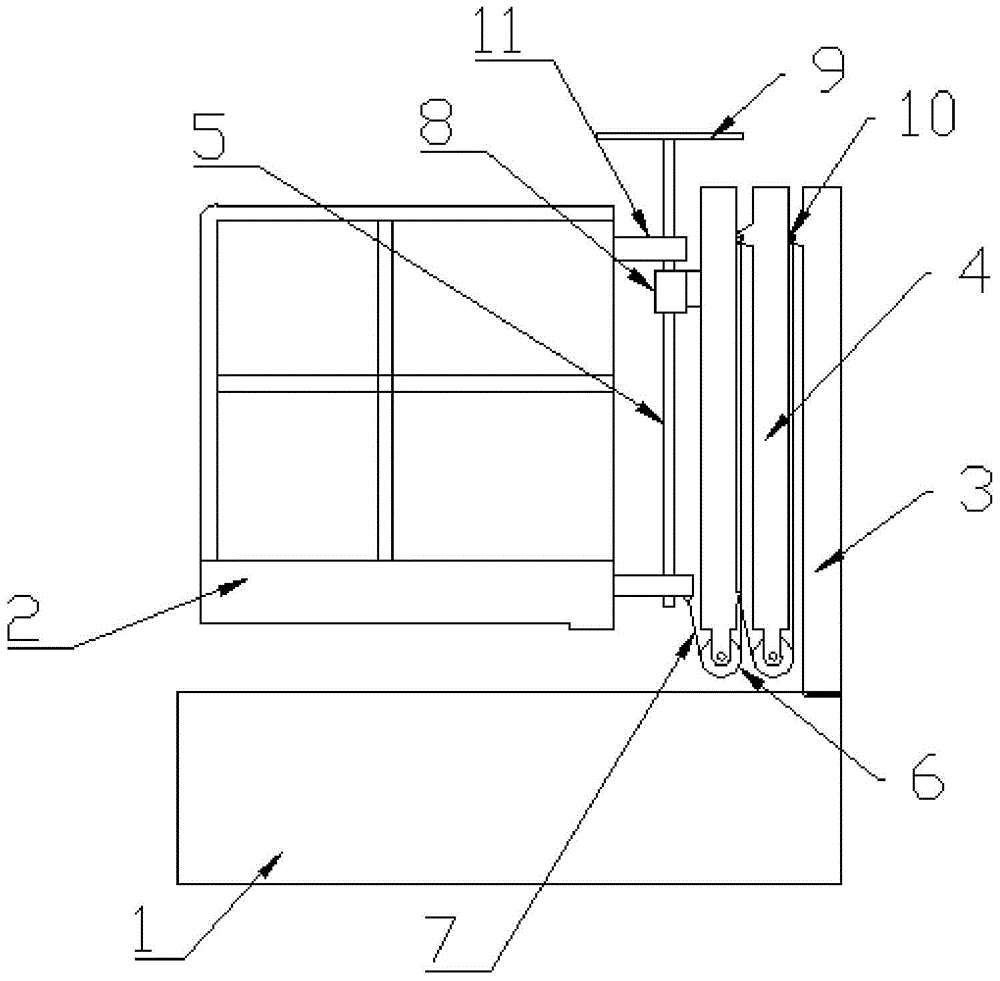

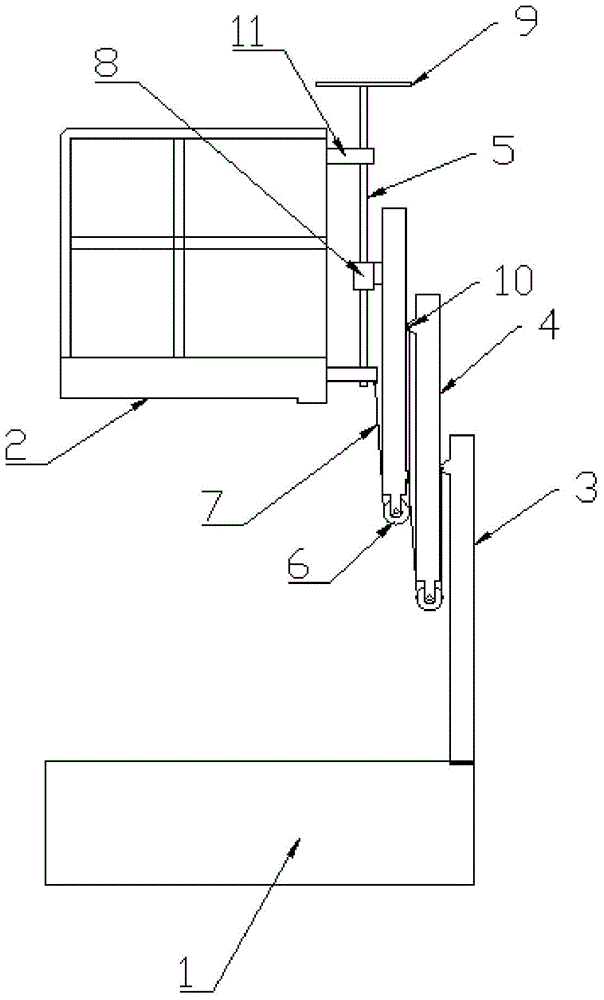

[0021] Such as figure 1 , 2 As shown, a vertical lifting mechanism includes a chassis 1, a loading platform 2 and a lifting mechanism arranged between the chassis and the loading platform for driving the loading platform to vertically lift. This elevating mechanism comprises fixed part 3, at least one movable part 4 and screw mandrel 5 that are arranged in sequence, and the lower end of fixed part 3 is fixed on the chassis; Chains 7 are respectively engaged; one end of the chain on the innermost movable part near the fixed part is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com