A kind of catalyst system and its application in the preparation reaction of aliphatic polyester

A technology of fatty acid polyester and catalyst, which is applied in titanium/aluminum catalyst system and the application field of preparing aliphatic polyester reaction, which can solve the problems of difficult preparation of molecular weight, long time, low catalyst activity, etc., and achieve simple operation process and easy The effect of control and smooth reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

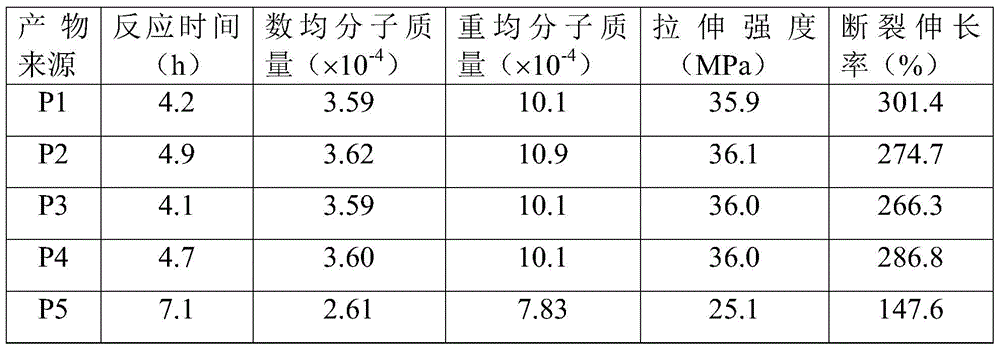

Examples

Embodiment 1

[0035] In a 500mL three-necked flask equipped with a mechanical stirrer, a thermometer and a condenser tube, add 141.6g of 1,4-butanedioic acid (purchased from Anhui Sanxin Chemical Co., Ltd.), 119.0g of 1,4-butanediol (purchased From Tianjin Guangfu Fine Chemical Research Institute), tetra-n-butyl titanate (Ti(OBu) 4 , purchased from Beijing Chemical Reagent Company), and the equivalent Ti(OBu) 4 0.5 times the molar amount of aluminum phosphate AlPO 4 (purchased from Tianjin Guangfu Fine Chemical Research Institute), at normal pressure N 2Heating with constant power under protection until fractions evaporate, collect the distilled fractions, and switch the vacuum distillation device when the fractions are no longer distilled and the top temperature of the condenser tube drops significantly, decompress gradually and heat with constant power until 250°C Keep the temperature, react for a certain period of time under the vacuum condition of the system pressure 180Pa, until the ...

Embodiment 2

[0040] In a 500mL three-neck flask equipped with a mechanical stirrer, a thermometer and a condenser tube, add 141.6g of 1,4-butanedioic acid and 119.0g of 1,4-butanediol, equivalent to 1,4-butanedioic acid moles 0.3% tetraisopropyl titanate Ti(OPr) 4 , and equivalent to Ti(OPr) 4 2 times the molar amount of aluminum phosphite Al 2 (HPO 3 ) 3 (purchased from Tianjin Guangfu Fine Chemical Research Institute), at normal pressure N 2 Under protection, heat with constant power until fractions evaporate, collect the corresponding fractions, switch the vacuum distillation device when the fractions no longer evaporate and the temperature drop at the top of the condenser tube drops significantly, gradually reduce the pressure and heat with constant power until 250°C Keep the temperature, and react for a certain period of time under the vacuum condition of the system pressure 200Pa. When the viscosity of the product no longer increases significantly, the N 2 Return to normal press...

Embodiment 3

[0045] In a 500mL three-neck flask equipped with a mechanical stirrer, a thermometer and a condenser tube, add 141.6g of 1,4-butanedioic acid and 119.0g of 1,4-butanediol, equivalent to 1,4-butanedioic acid moles 0.3% tetra-n-propyl titanate, and aluminum monohydrogen phosphate Al equivalent to 5 times the molar amount of tetra-n-propyl titanate 2 (HPO 4 ) 3 , at atmospheric pressure N 2 Under protection, heat with constant power until fractions evaporate, collect the corresponding fractions, switch the vacuum distillation device when the fractions no longer evaporate and the temperature drop at the top of the condenser tube drops significantly, gradually reduce the pressure and heat with constant power until 250°C Keep the temperature, and react for a certain period of time under the vacuum condition of the system pressure 200Pa. When the viscosity of the product no longer increases significantly, the N 2 Return to normal pressure or pressurized discharge under protection ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap