Method for reducing zinc powder consumption in process of purifying zinc sulfate solution

The technology of zinc sulfate solution and zinc powder is applied in the direction of improving process efficiency, which can solve the problems of large consumption of zinc powder in electric furnace, and achieve the effects of remarkable economic benefit, improved reaction speed and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

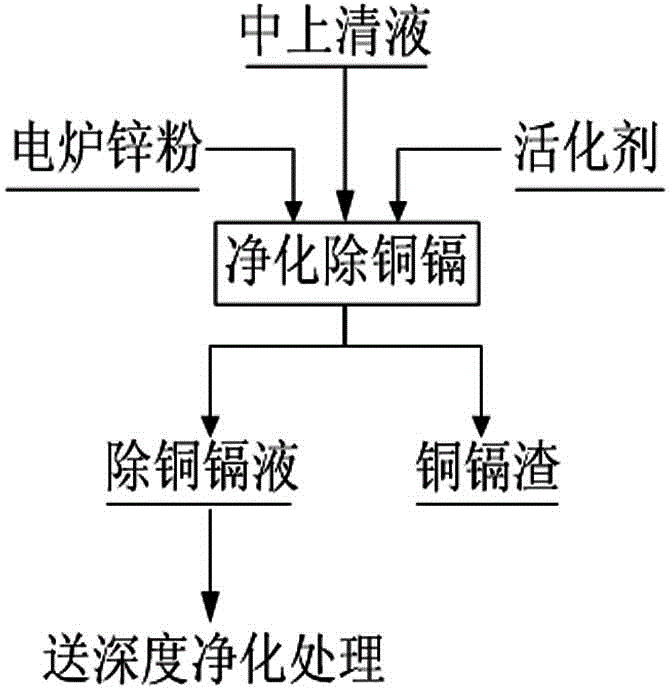

Method used

Image

Examples

Embodiment 1

[0017] ①Take 4L of the middle supernatant of zinc sulfate solution produced in the leaching section of the hydrometallurgy system of a smelter, pH=5-5.4, the main components are: Zn 120.56g / L, Cu 168.23mg / L, Cd 1560mg / L L, Co 2.14 mg / L, Ni 2.04 mg / L, As 0.17 mg / L, Sb 0.53 mg / L, F 150.31 mg / L, Cl 425.78 mg / L. Under agitation, heat the middle supernatant to 50-60°C.

[0018] ② Add the waste electrolyte produced by the electrolysis of the zinc system (you can also add acetic acid, nitric acid or phosphoric acid), and control the pH of the solution to 1.5.

[0019] ③Slowly add 5.14g of 365-mesh electric furnace zinc powder required for the displacement reaction, and the metal zinc content in the electric furnace zinc powder is 86%. The reaction time is 30 minutes.

[0020] ④ After the reaction, filter the solution to obtain copper and cadmium removal solution and copper and cadmium slag. The copper and cadmium removal solution contains Cu 0.26mg / L and Cd 16.01mg / L, which is sen...

Embodiment 2

[0022] ① Take 4L of the middle and supernatant of zinc sulfate solution produced in the leaching section of the hydrometallurgy system of a smelter, pH=5-5.4, the main components are: Zn 125.89g / L, Cu 350.91mg / L, Cd 2180mg / L L, Co 1.97mg / L, Ni 2.33 mg / L, As 0.14mg / L, Sb 0.46mg / L, F 145.28 mg / L, Cl 480.16mg / L. Under agitation, heat the middle supernatant to 50-60°C.

[0023] ② Add sulfuric acid to control the pH of the solution to 4.5.

[0024] ③Slowly add 7.63g of 120-mesh electric furnace zinc powder required for the displacement reaction, and the metal zinc content in the electric furnace zinc powder is 87%. The reaction time is 55min.

[0025] ④ After the reaction, filter the solution to obtain copper and cadmium removal solution and copper and cadmium slag. The copper and cadmium removal solution contains Cu 0.13mg / L and Cd 19.28mg / L, which is sent to the deep purification section for cobalt and nickel removal; the copper and cadmium slag contains Cu 9.43%, Cd 52.61%, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com