Method for producing colored spun yarn

A technology of color spinning and color, which is applied in the field of drawing frame in the production of color spinning yarn, can solve the problem of sliver lack of thickness change in the longitudinal direction, color change, etc., to achieve the effect of ensuring stability and controllability, and easy control of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

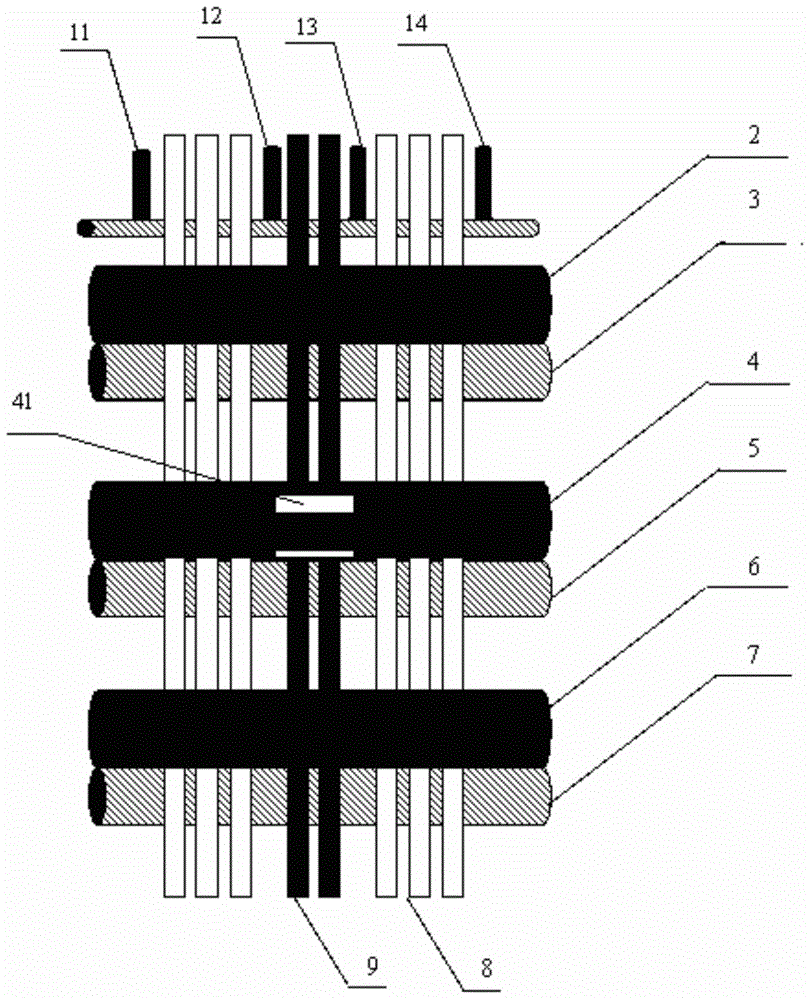

Method used

Image

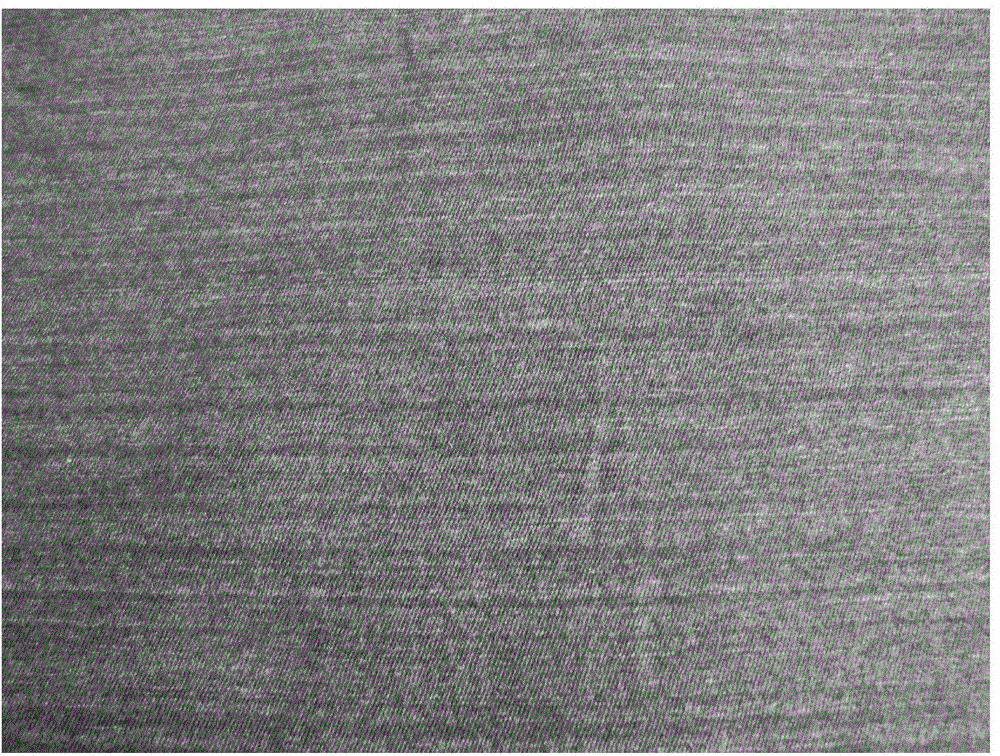

Examples

Embodiment 1

[0047] The method for producing colored spinning yarn in the present embodiment may further comprise the steps:

[0048] 1. Spinning of A:

[0049] According to the product requirements, dye the cotton fiber of strip A to make the fiber reach the required black color. A small amount of mixing is carried out in several groups with white cotton at a ratio of 50% in color ratio. After the raw materials are mixed, in the cleaning process, the cleaning machine is FA002-FA035E-FA106-FA076-A092A, which further mixes various raw materials of different colors and properties and quantitatively forms them into rolls. The dry weight of cotton rolls is 420 g / m, lap length 37m. On the FA201B carding machine, the colored cotton laps are carded into slivers, and the raw sliver dry weight is 20.5 g / 5 m, and then doubled into 20.5 g / 5 m by the FA317 drawing frame.

[0050] 2. Spinning of B:

[0051] Select uncolored cotton for a small amount of mixing in several groups. After the raw mater...

Embodiment 2

[0086] 1. In the spinning step of A, the quantitative amount of A is 13 grams / 5 meters;

[0087] 2. In the spinning step of B, the quantification of B is 13 grams / 5 meters;

[0088] 3. The weight of final drawing frame in final drawing spinning is 13g / 5m;

[0089] 4. The roving weight in the roving process is 4.1 g / 10 meters; the twist coefficient is 80.

[0090] Others are the same as embodiment 1.

Embodiment 3

[0092] 1. In the spinning step of A, the quantitative amount of A is 26 grams / 5 meters;

[0093] 2. In the spinning step of B, the quantification of B is 26 grams / 5 meters;

[0094] 3. The weight of final drawing frame in final drawing spinning is 26g / 5m;

[0095] 4. In the roving process, the roving weight is 7.0 g / 10 meters; the twist coefficient is 120.

[0096] Others are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| twist factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com