Control system and adjustment method for fiber guide ring of circular three-dimensional braiding machine

A technology of a three-dimensional weaving machine and control system, which is applied in the direction of braided fabrics, textiles, and papermaking. It can solve the problems of fluctuations in different parts of the braiding angle and affect the weaving effect, and achieve the effect of improving the weaving quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

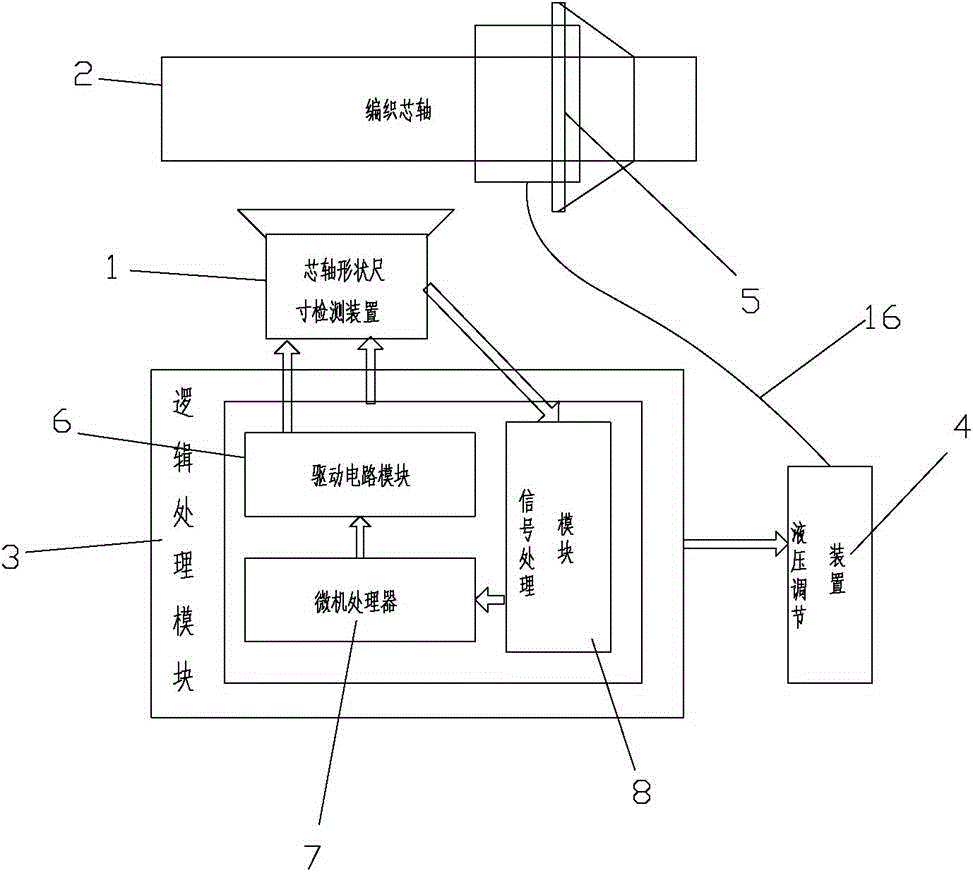

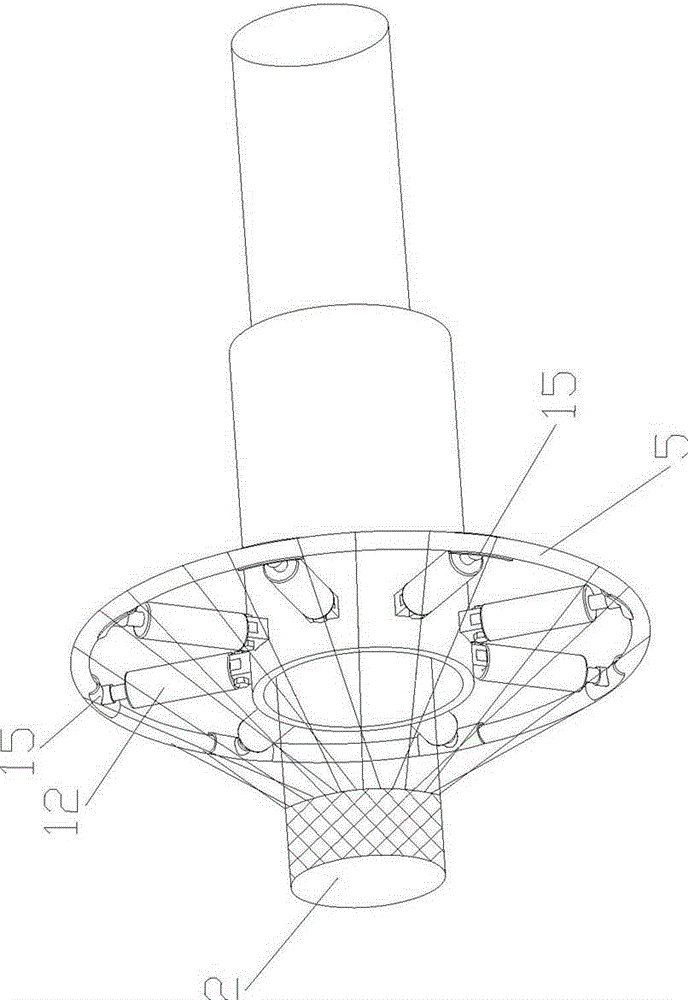

[0022] Please refer to the attached figure 1 to attach image 3 As shown, the present invention is a fiber guide ring control system for an annular three-dimensional knitting machine, which consists of a mandrel shape and size detection device 1, a braiding mandrel 2, a logic processing module 3, a hydraulic adjustment device 4, and an adjustable fiber guide ring 5, etc. It consists of several parts.

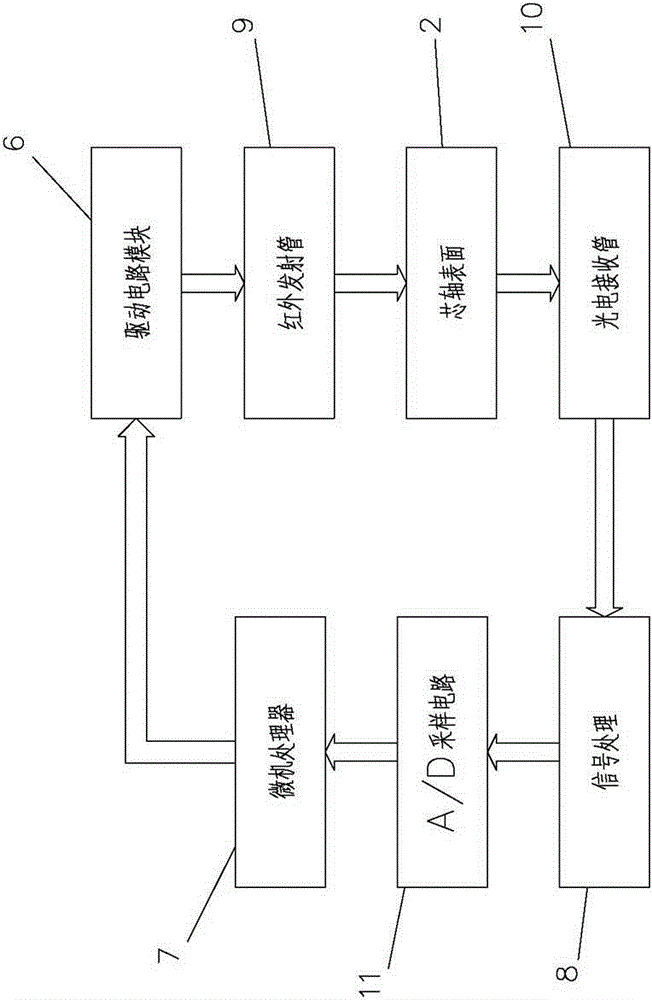

[0023] Wherein, the mandrel shape and size detection device 1 is set opposite to the braiding mandrel 2, and an infrared emitting tube 9 and a photoelectric receiving tube 10 are installed therein.

[0024] The logic processing module 3 is connected with the hydraulic regulating device 4 and includes a microcomputer processor 7 , a drive circuit module 6 and a signal processing module 8 . Wherein, the microcomputer processor 7 is connected with the driving circuit module 6 . The driving circuit module 6 is connected with an infrared emitting tube 9 . The photoelectric receiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com