Valve spool transfer combined hydraulic shock excitation control valve

A control valve and composite technology, which is applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problem of large hydraulic power of the spool, difficult sealing of the spool, poor linearity of axial displacement adjustment flow, etc. problem, to achieve the effect of eliminating gaps, increasing accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

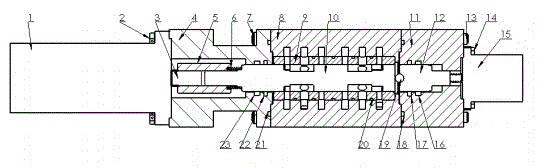

[0056] Such as figure 1 As shown, the spool transfer composite hydraulic excitation control valve 108 of the present invention includes a valve body 8, the inner cavity of the valve body 8 is fixedly provided with a valve sleeve 9, and a valve core 10 is movable inside the valve sleeve 9; the valve core 10 can Relative to the rotational movement of the valve sleeve 9, it can also move axially in the valve sleeve 9;

[0057] The right end of the spool 10 is offset against the steel ball 19; the plug 12 presses the right end of the spool 10 through the steel ball 19 to act as an axial positioning of the right end of the spool 10; the right end of the plug 12 is connected to the linear motor 15 through a screw; The rotation of the linear motor 15 drives the screw rod to move linearly left and right, and the screw rod drives the valve core 10 to move linearly left and right through the plug 12; The left end face of the valve body 8 is against the valve body 8, and an O-ring 18 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com