Buffer hydraulic cylinder

A buffer hydraulic cylinder and cylinder body technology, applied in the field of buffer hydraulic cylinders, can solve the problems that the buffer effect at the end of the stroke may not meet the requirements, affect the normal service life and precision of the hydraulic cylinder, and achieve novel overall structure, novel structure, and easy processing simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

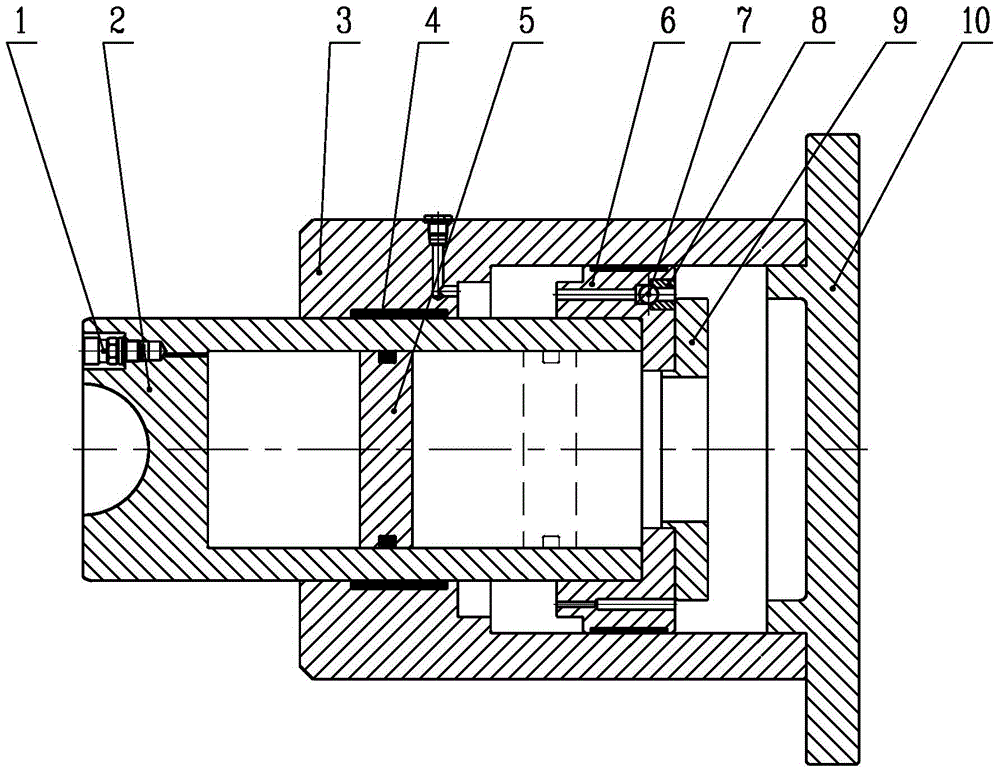

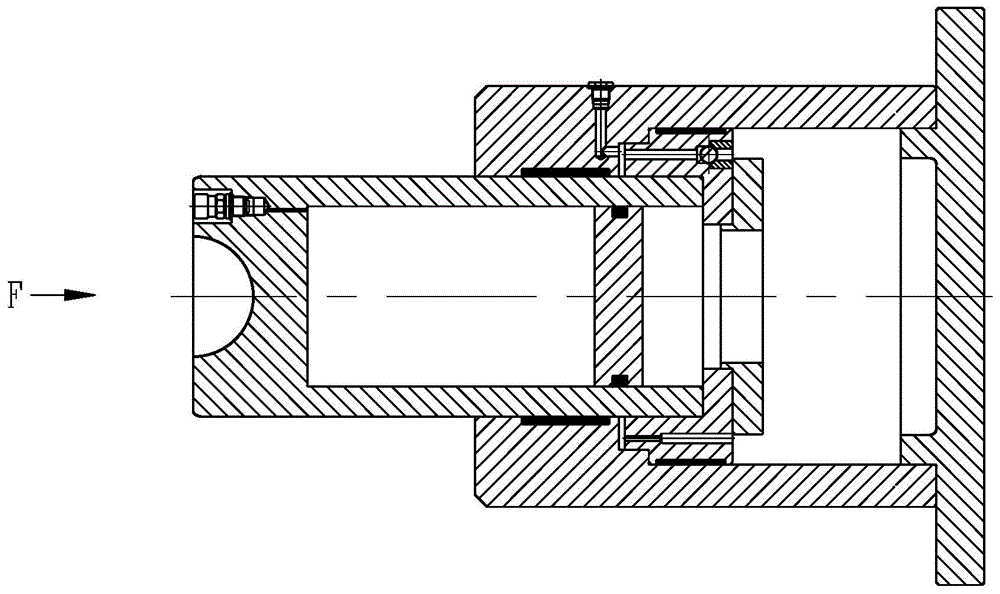

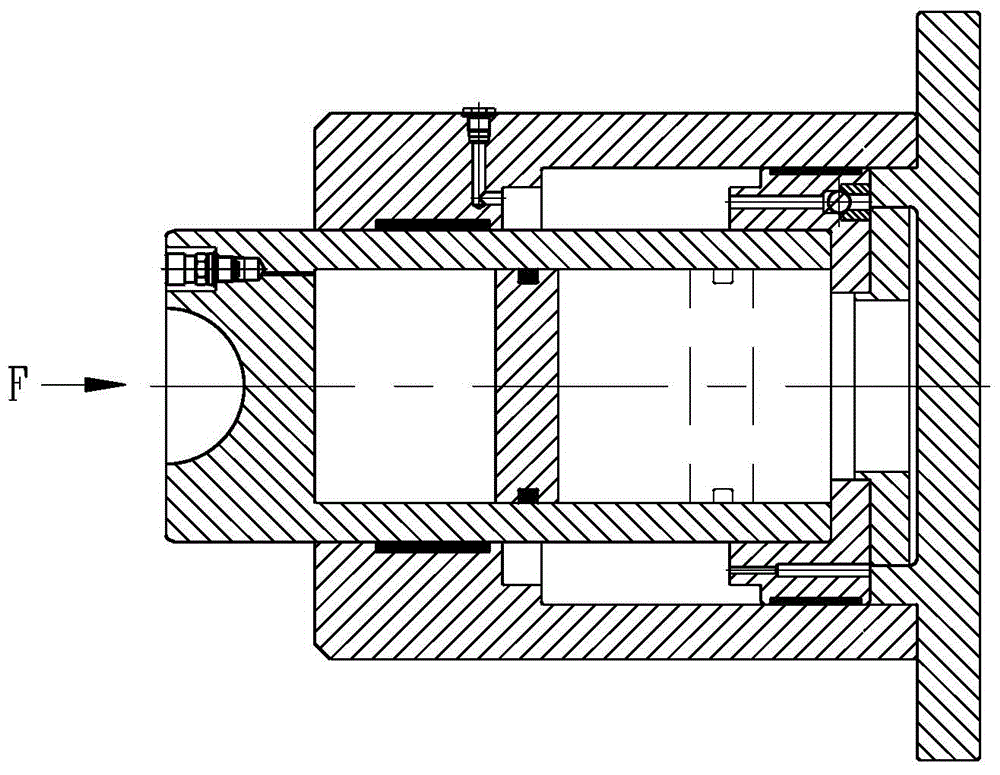

[0022] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0023] as attached figure 1 As shown, the present invention provides a buffer hydraulic cylinder, including an air charging valve 1, a plunger rod 2, a cylinder body 3, a seal 4, an air piston 5, a piston 6, a steel ball 7, a retaining ring 8, a gland 9, Cylinder bottom 10;

[0024] One end surface of the plunger rod 2 is processed with an arc groove, the arc groove matches the vibration part of the damped equipment, the end is equipped with an inflation valve 1, and the other end of the plunger rod 2 is cylindrical cavity;

[0025] as attached Figure 4 , 5 As shown in and 6, two groups of step through holes are processed on the piston surface of the piston 6, the first group of step through holes are steel ball installation valve holes, the steel ball is limited in the step hole by the retaining ring 8, and the retaining ring 8 and The steel ball is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com