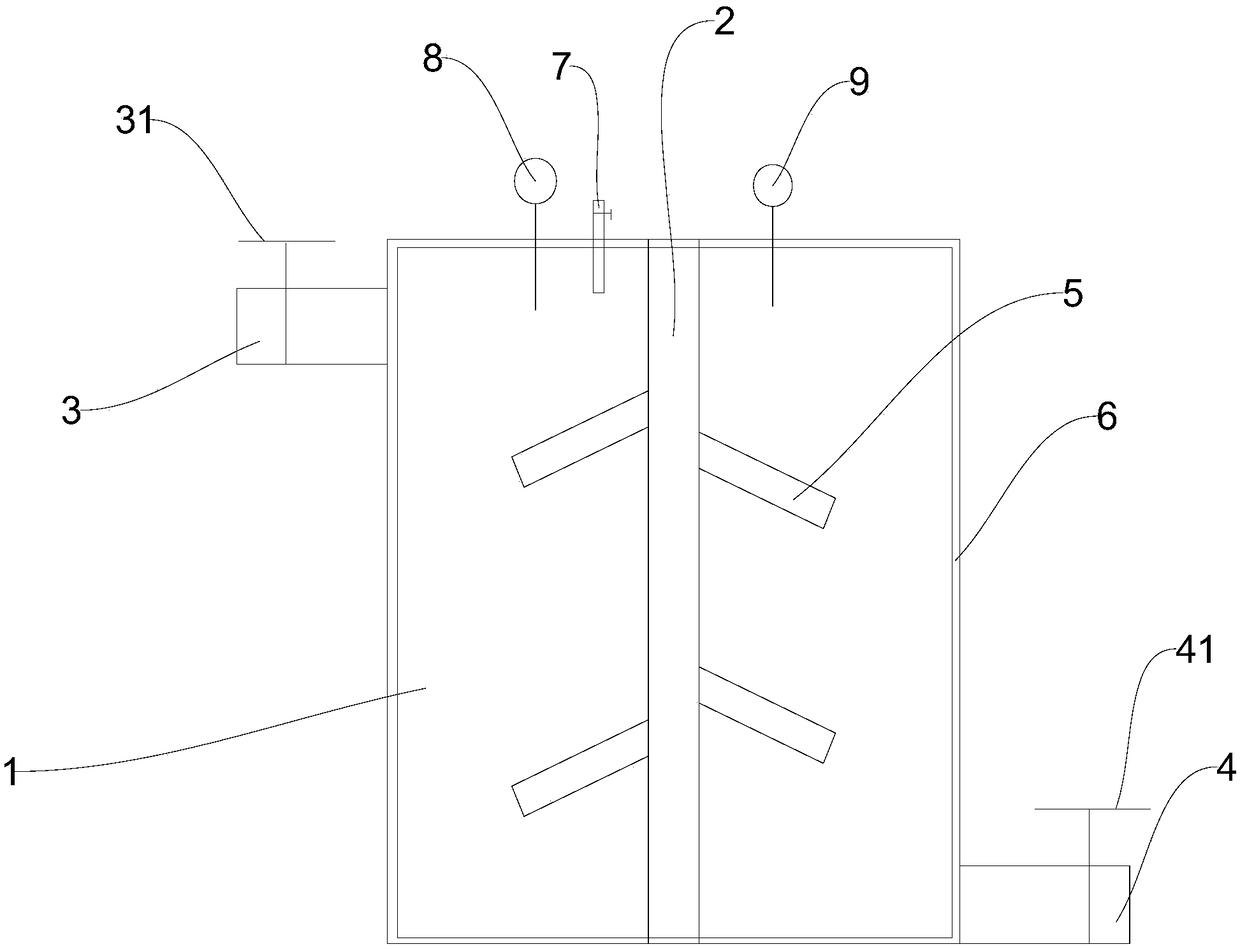

A liquor brewing device of a fragrant liquor

A technology for fragrance-type liquor and equipment, which is applied in the field of brewing equipment for fragrance-type liquor, can solve problems such as damage, influence on the flavor and quality of liquor products, and short service life, and achieves the effect of improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The composite coating is made of the following raw materials in parts by weight: 30 parts of hydroxypropyl cellulose, 2 parts of zirconia, 3 parts of kaolin, 2 parts of zeolite powder, 150 parts of ethanol, 1 part of ethylene glycol, 1 part of three Glyceryl acetate, 2 parts of Luo Han Guo seed extract, 6 parts of lychee seed extract; of which,

[0028] Said Luo Han Guo seed extract is: add the water of 4 times of its quality to Luo Han Guo seed, and make slurry, add the yeast of its total mass 1.2% to described slurry, at the constant temperature of 25 ℃ Ferment in an incubator for 30 hours, filter the obtained fermentation liquid, and sterilize the obtained clarified liquid, which is the Luo Han Guo seed extract;

[0029] The lychee core extract is as follows: crush the lychee core, add an ethanol solution with a volume concentration 3 times its weight and a volume concentration of 88% to it for reflux extraction for 4 hours, then filter, and concentrate the obtained ...

Embodiment 2

[0034]The composite coating is made of the following raw materials in parts by weight: 35 parts of hydroxypropyl cellulose, 3 parts of zirconia, 5 parts of kaolin, 2 parts of zeolite powder, 180 parts of ethanol, 2 parts of ethylene glycol, 3 parts of three Glyceryl acetate, 4 parts of Luo Han Guo seed extract, 8 parts of litchi core extract; of which,

[0035] Said Luo Han Guo seed extract is: add the water of 6 times of its mass to Luo Han Guo seed, and make slurry, add the yeast of its total mass 1.5% to described slurry, in the constant temperature of 28 ℃ Ferment in the incubator for 32 hours, filter the obtained fermentation liquid, and sterilize the obtained clarified liquid, which is the Luo Han Guo seed extract;

[0036] The lychee core extract is as follows: crush the lychee core, add an ethanol solution with a volume concentration 5 times its weight and a volume concentration of 90% to it for reflux extraction for 6 hours, then filter, and concentrate the obtained f...

Embodiment 3

[0041] The composite coating is made of the following raw materials in parts by weight: 32 parts of hydroxypropyl cellulose, 2.5 parts of zirconia, 4 parts of kaolin, 3 parts of zeolite powder, 160 parts of ethanol, 1.5 parts of ethylene glycol, 2 parts of three Glyceryl acetate, 3 parts of Luo Han Guo seed extract, 7 parts of lychee seed extract; of which,

[0042] Said Luo Han Guo seed extract is: add the water of 5 times of its quality to Luo Han Guo seed, and make slurry, add the yeast of its gross mass 1.4% to described slurry, at the constant temperature of 26 ℃ Ferment in an incubator for 31 hours, filter the obtained fermentation liquid, and sterilize the obtained clarified liquid, which is the Luo Han Guo seed extract;

[0043] The lychee core extract is as follows: crush the lychee core, add an ethanol solution with a volume concentration 4 times its weight and a volume concentration of 89% to it for reflux extraction for 5 hours, then filter, and concentrate the obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com