Self-ballasted flexible LED lamp filament and LED bulb formed thereby

A technology for LED filaments and LED bulbs, which is applied in the direction of optical elements used to change the spectral characteristics of emitted light, electric lamp circuit layout, lighting device components, etc., and can solve problems such as large-scale high-efficiency production, LED chip failure, contact Bad and other problems, to achieve mass production, optimize product structure, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

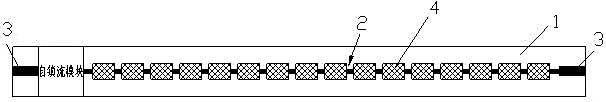

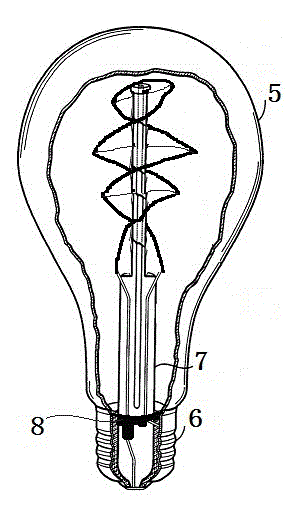

[0018] See attached figure 1 As shown, it is a schematic diagram of a self-ballasted flexible LED filament according to the present invention, which includes a flexible substrate 1, on which a connecting line 2 is prepared, electrodes 3 are formed at both ends of the connecting line 2, and the connecting line 2 is formed on the electrode A plurality of pads 4 are formed between the 3, and a flip-chip LED chip 5 is installed between each pair of pads 4. The flexible substrate 1 and the LED chip 5 are covered with sleeves or wrapped with silicone body by injection molding, and the connection lines 2 is provided with a self-ballasting module, which is used to convert the input mains power into a DC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com