Head lamp for vehicle

A vehicle and headlight technology, applied in the field of headlights, can solve the problems of reduced luminous efficiency, increased weight and cost, and increased overall optical size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, a headlamp for a vehicle according to an exemplary embodiment of the present inventive concept will be described with reference to the accompanying drawings.

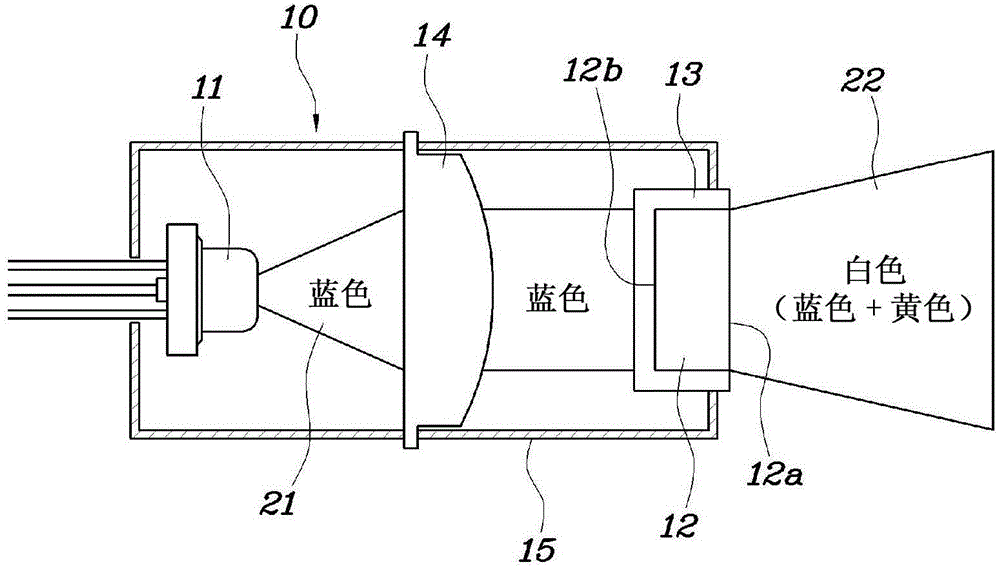

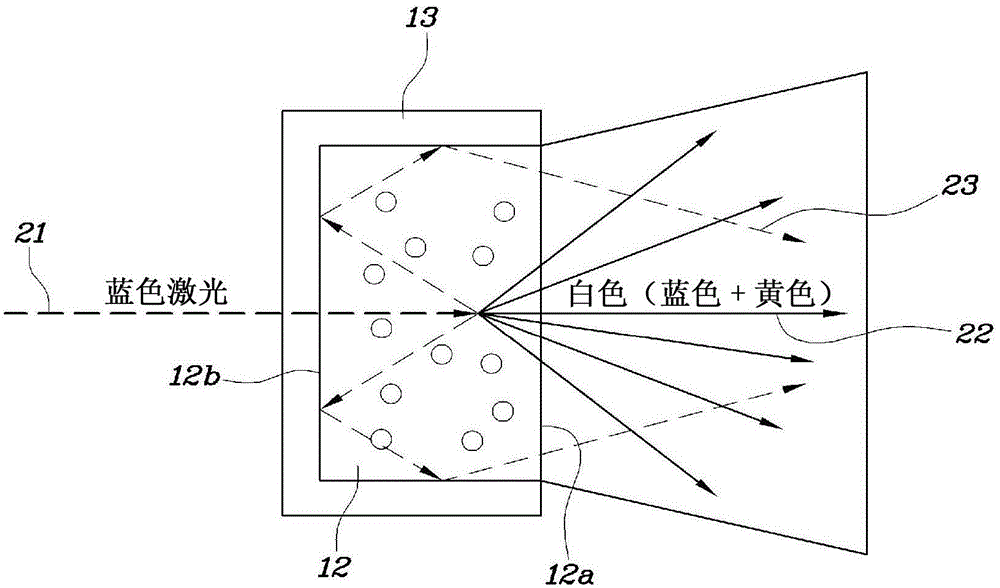

[0027] refer to figure 2 and image 3 , the headlamp for a vehicle according to an exemplary embodiment of the present inventive concept includes a laser light source module 10 . The laser light source module 10 includes a laser diode 11 that generates a laser beam 21 in the blue wavelength range (typically a short wavelength of 450 nm). Phosphor 12 is installed in front of laser diode 11 and reacts with light from laser diode 11 to output white light 22 . The short-pass filter 13 is coupled to the phosphor 12 to transmit the laser beam 21 from the laser diode 11 to the phosphor 12 and to avoid the laser beam 21 incident on the phosphor 12 from the phosphor 12 Light scattered in the direction of the light-emitting surface 12 a is reflected back to the phosphor 12 .

[0028] Here, the short wave ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com