Both-end clamped piezoelectric beam vibration detection and control device based on non-contact type sensor

A vibration detection and detection control technology, applied in measurement devices, vibration testing, electrical devices, etc., can solve problems such as large measurement noise, change the structural characteristics of flexible boards, etc., achieve high measurement accuracy, and realize vibration detection and control research. , Dynamic response and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

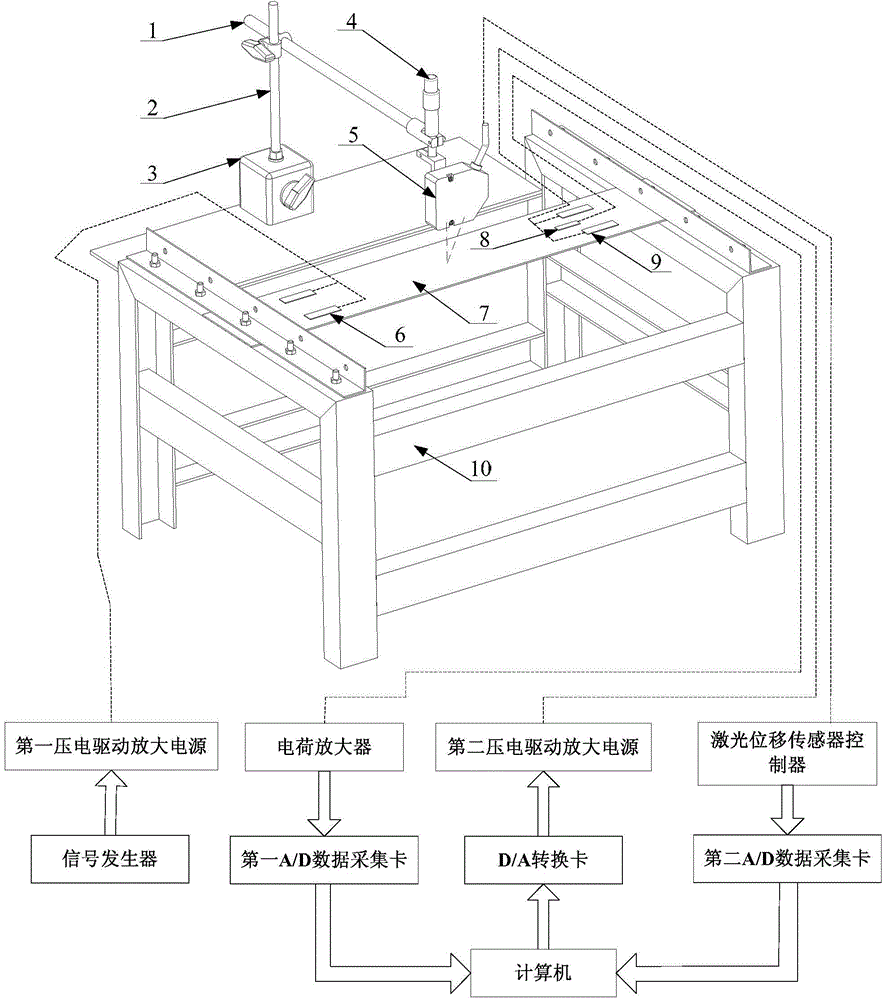

[0034] Such as Figure 1-Figure 6 As shown, a vibration detection and control device of a piezoelectric beam with fixed supports at both ends based on a non-contact sensor, including a flexible beam body, a vibration excitation part, a vibration detection part and a vibration control part;

[0035] The flexible beam body includes a flexible beam 7, and the two ends of the flexible beam 7 are fixed by a mechanical clamping device. The flexible beam is placed horizontally, and the mechanical clamping device is fixed on the base 10.

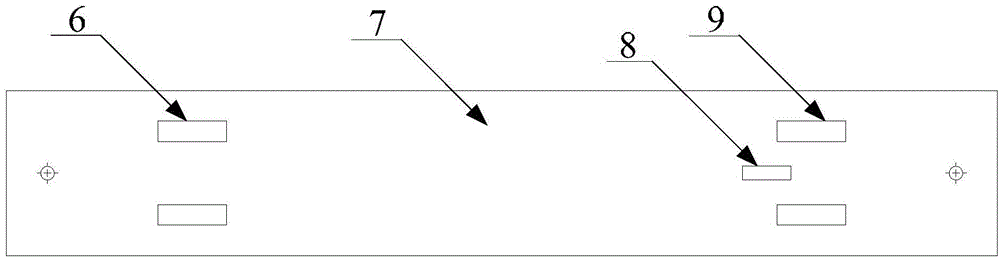

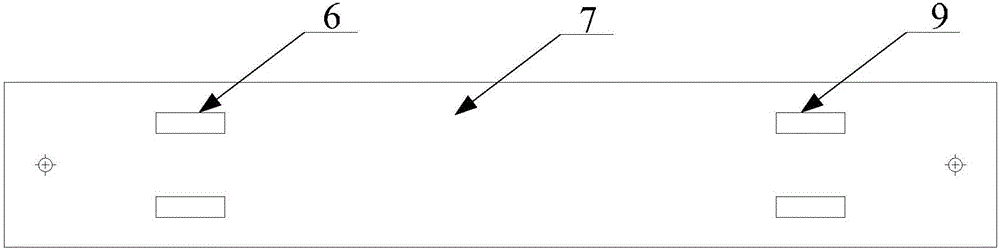

[0036] The vibration excitation part includes a signal generator, a first piezoelectric driving amplifying power supply and a piezoelectric excitation driver 6; at the left end of the flexible beam, 50 mm from the width edge of the flexible beam 7, and 22 mm from the length edge, the attitude angle is 0 °, double-sided Symmetrically paste 4 pieces of piezoelectric ceramic sheets, 2 pieces on each side, the polarity of the two sides is opposite and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com