A movement assembly accuracy detection jig and detection method thereof

A technology for assembly accuracy and detection fixtures, which is applied to measuring devices, instruments, etc., can solve the problems of the detection accuracy not meeting the design requirements, the difficulty of batch detection, and high labor intensity, so as to reduce the labor intensity of workers, simplify the structure, improve The effect of factory pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

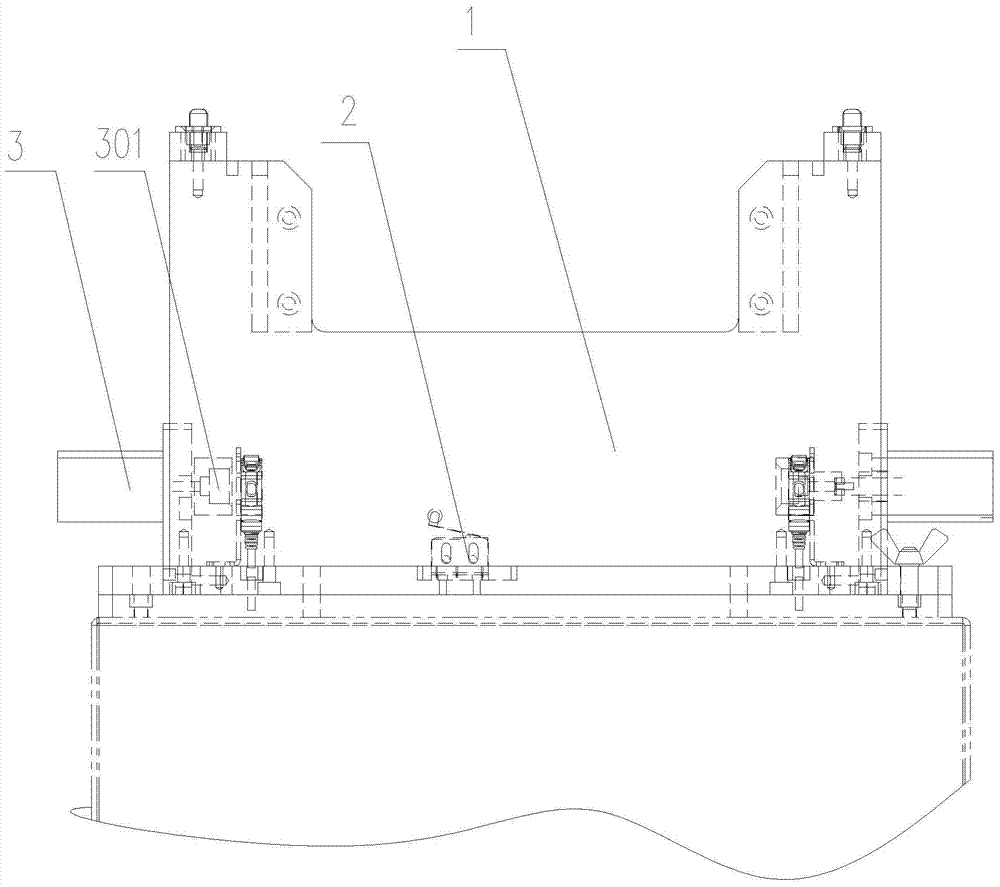

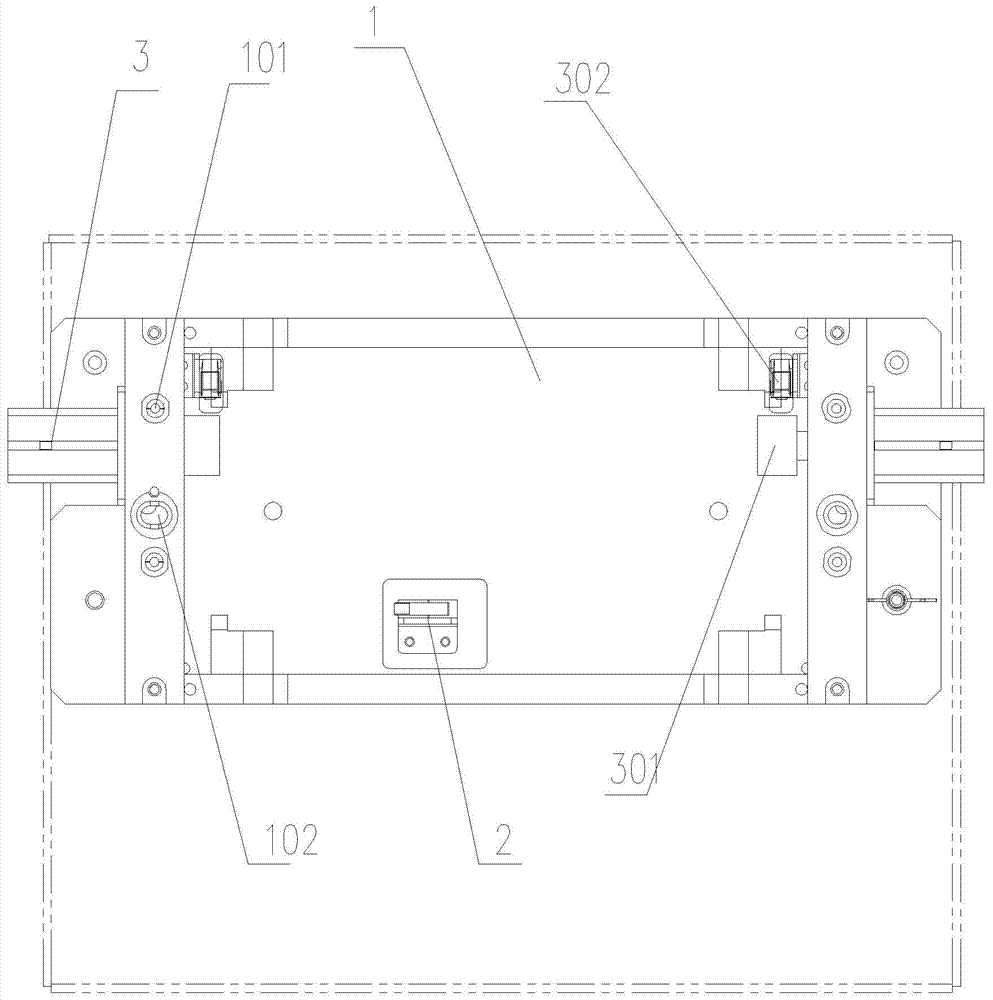

[0023] refer to figure 1 and figure 2 , the present invention provides a movement assembly accuracy detection jig, which includes a placement bracket 1 for placing the movement, the placement bracket 1 includes a bottom plate, two side plates vertically installed on the bottom plate, and two side plates fixed on both sides The top is also used to connect the connecting plate of the two side plates, and the accommodation cavity for accommodating the movement is formed between the two side plates, and the connecting plate is used to support the whole movement. The test needle 101 and the positioning pin 102 corresponding to the pin hole on the movement are provided with a micro switch 2 for detecting whether the movement is installed in place on the upper bottom surface of the bottom plate. In this embodiment, the micro switch is an Omron The switch i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com