Self-heating differential thermoresistor liquid level sensor and liquid level measurement method thereof

A technology of liquid level sensor and thermal resistance, which is applied to the liquid level indicator of physical variable measurement, etc., can solve the problems of medium density fluctuation, short service life, low reliability, etc., and achieves simple structure, reliable performance, and anti-interference. powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

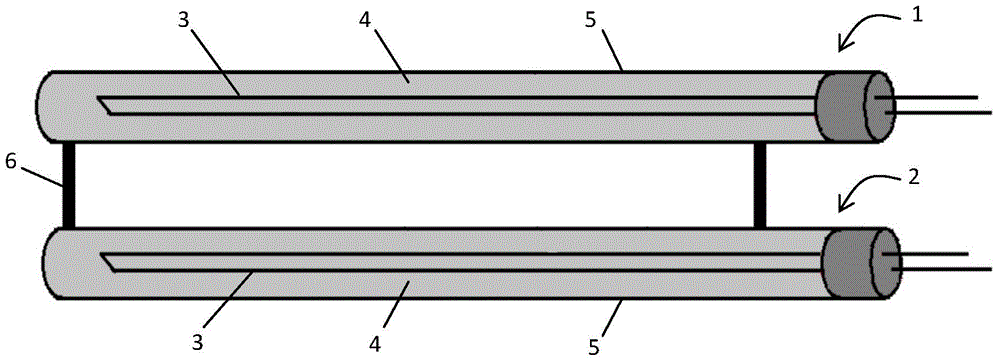

[0014] The liquid level sensor provided by the present invention adopts two armored thermal resistors of the same structure and equal quality as sensitive elements, and the thermal resistance wire in one of the sensitive elements is heated by itself with electricity to sense the liquid level, which is called a measuring element. The other one is not heated by electricity, and it is used to measure the ambient temperature and compensate for the influence of the ambient temperature, which is called a compensation element. The thermal resistances of the two sensitive elements are connected differentially or output independently, and the resistance values are subtracted to form a resistance difference. The specific resistance measurement method is a well-known technique in the art, and will not be repeated here. The liquid level sensor utilizes the obv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com