Electric drive test device to realize the movement of the front cover, rear cover or door switch of the car

A test device, electric drive technology, applied in vehicle testing, measuring device, machine/structural component testing, etc., can solve problems such as increased test cost, increased operating noise, uncontrollable impact speed, etc., and achieves the total test time. The effect of shortening, reducing operating noise, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] It should be noted that the principles, characteristics and advantages of the electric drive test device for realizing the movement of the front cover, rear cover or door switch of the present invention will be specifically described below by way of example, but all descriptions are only used to carry out illustrative, but they should not be construed as forming any limitation on the present invention. In addition, any single technical feature described or implied in each embodiment mentioned herein, or any single technical feature shown or implied in each drawing, can still be included in these technical features (or their equivalents) Objects) continue to make any combination or deletion, so as to obtain more other embodiments of the present invention that may not be directly mentioned herein.

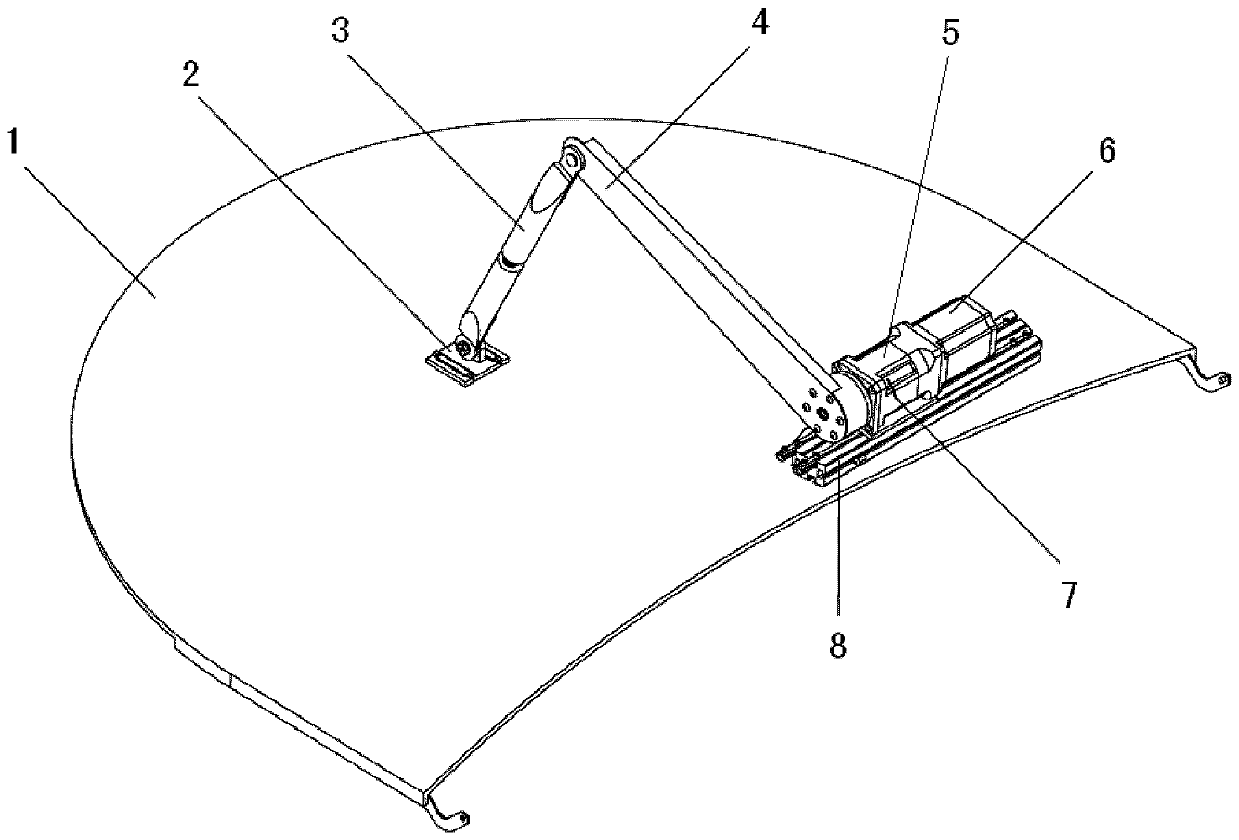

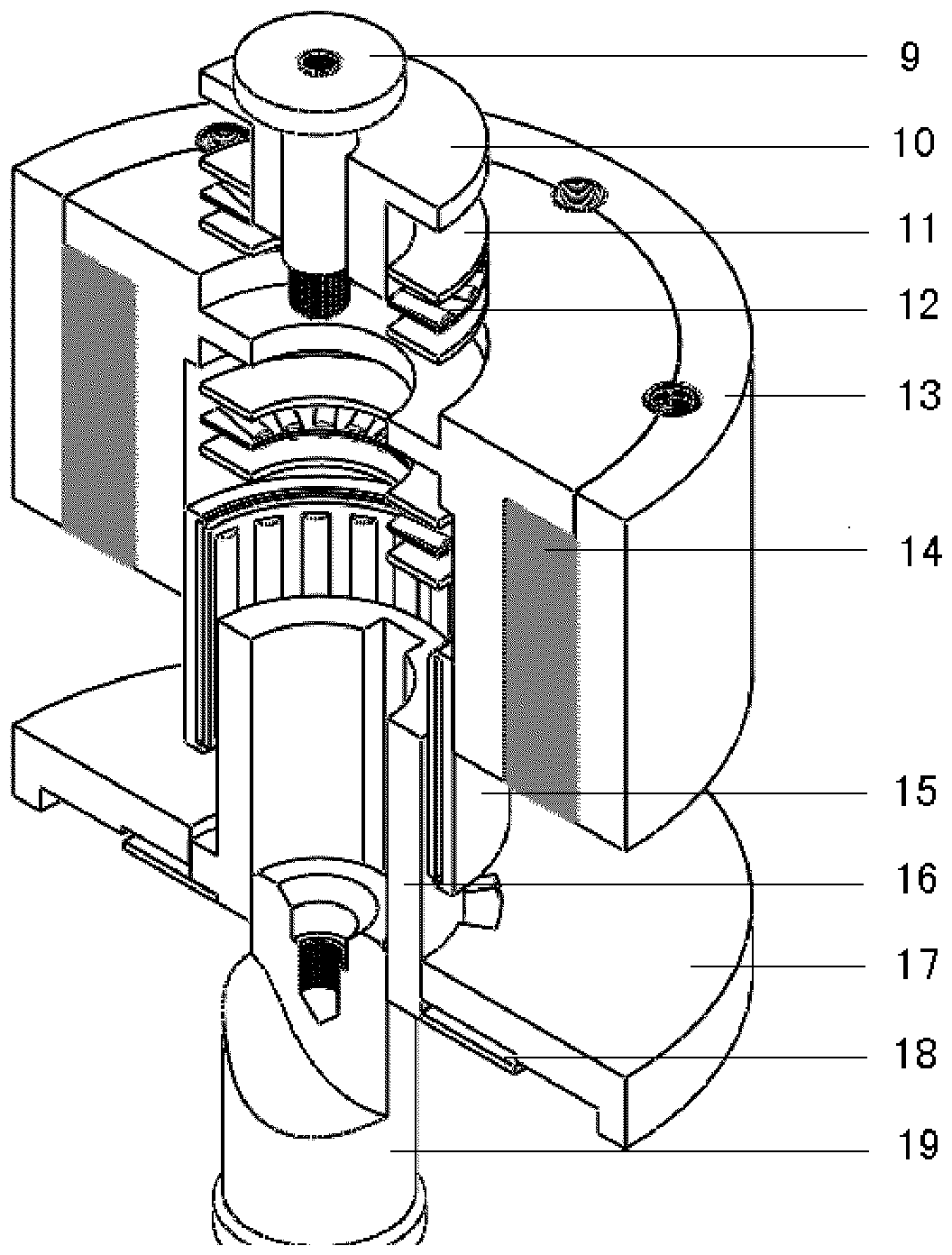

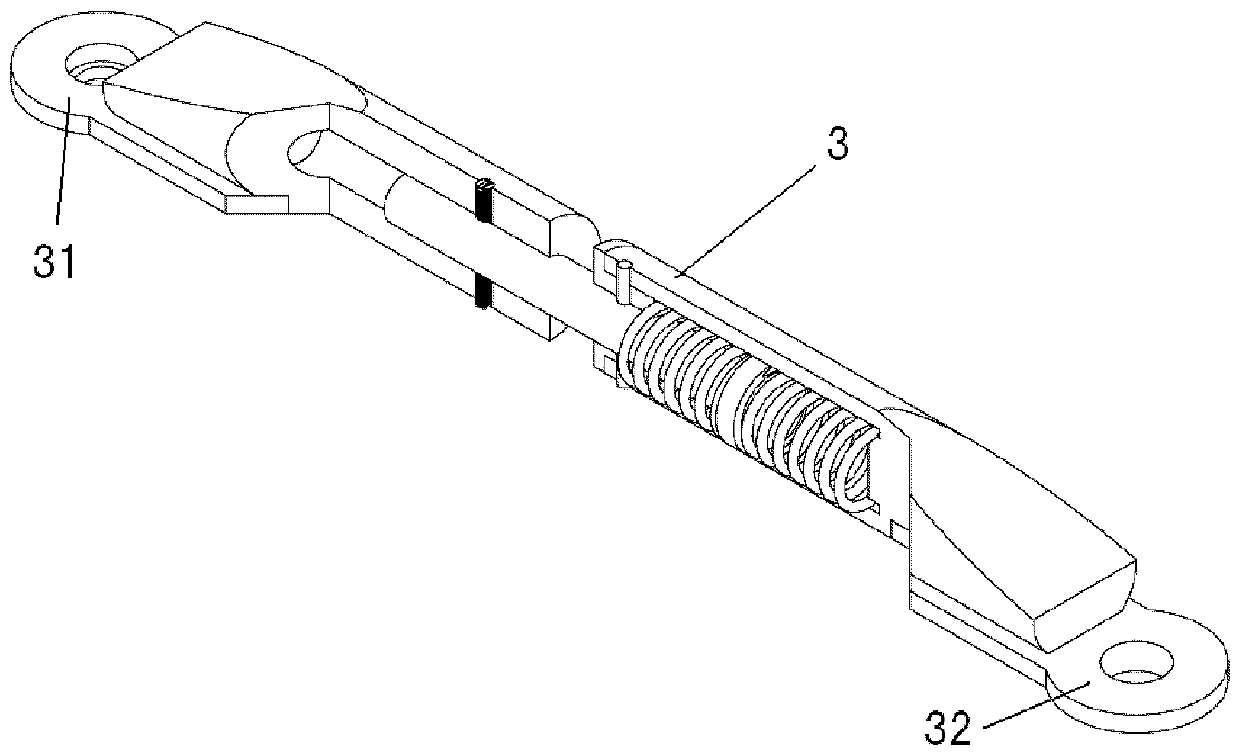

[0034] figure 1 Schematically shows the basic structure of an embodiment of the electric drive test device for realizing the movement of the front cover, rear cover or door s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com