Method for automatically detecting and evaluating color of laser beam emitting paper and quality of laser beams

A technology of automatic detection and evaluation method, applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of uncertain measurement results and human errors, and achieve the effect of reliable results, small errors and fast measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

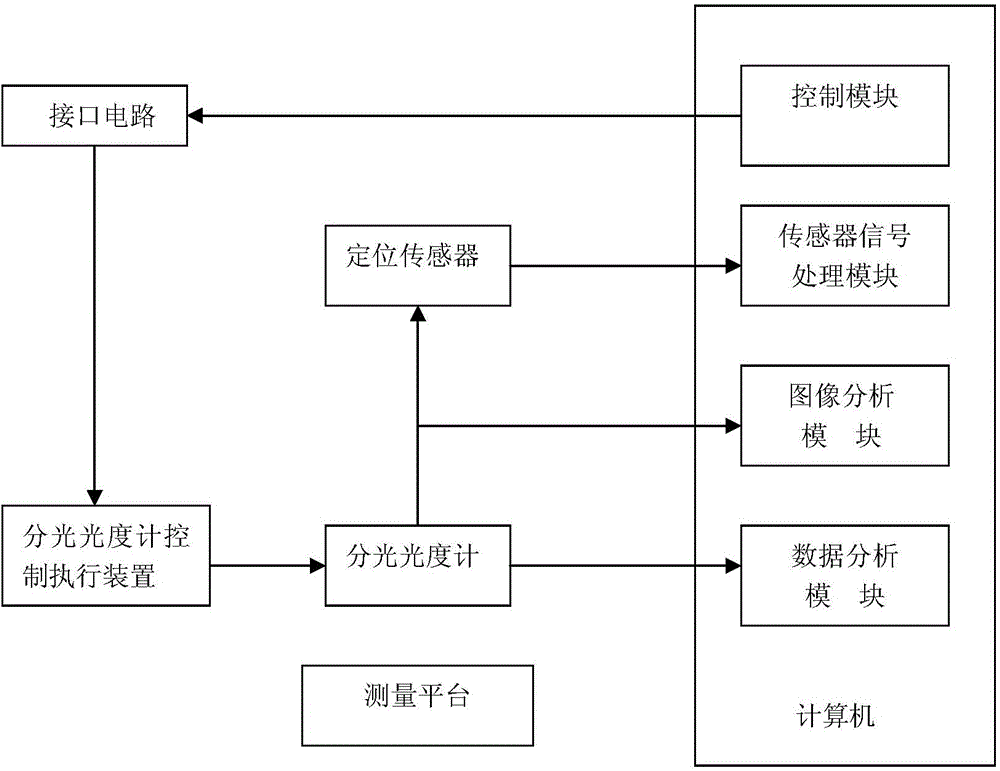

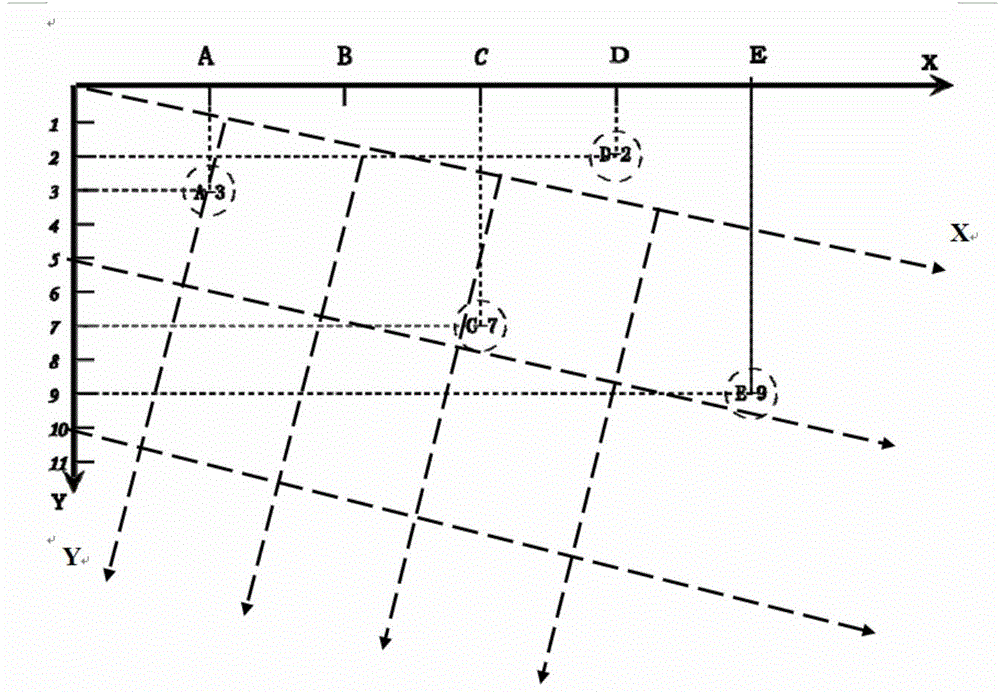

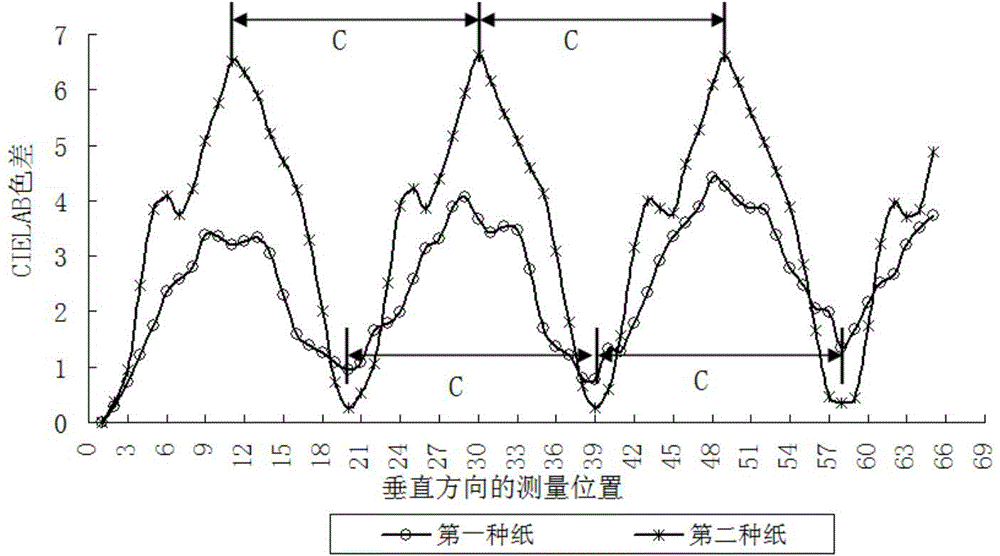

[0031] The invention can automatically detect and evaluate the color of the light column laser paper and the quality of the light column. First of all, it is necessary to determine the sampling and displacement of the color measuring instrument at different measuring positions, and the measurement system of the present invention precisely controls the position of the measuring point of the color measuring instrument on the light column laser paper sample, so that the color measuring instrument is moved along the X and Y directions by a certain step length Carry out measurement, automatically measure the color value of each point, and calculate the CIELAB (or CIEDE2000) color difference value between different sampling points, so as to obtain the uniformity of the color of the single laser paper sample and the quality of the light column, and compare the measured value with the color of the standard sample By comparison, the quality evaluation of the samples can be obtained.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com