High-speed optical cable sleeve pipe production equipment

A technology for production equipment and optical cables, applied in the field of communication equipment production equipment, can solve the problems affecting the production speed of optical fiber sleeves, the total length of the equipment, and the large site constraints, so as to save production space, eliminate the increase in the excess length of the sleeve, and save effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

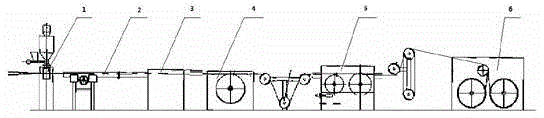

[0019] Such as figure 1 As shown, 1 is the machine head, 2 is the hot water tank, 3 is the hot water tank, 4 is the main traction, 5 is the cold water tank, and 6 is the automatic take-up system.

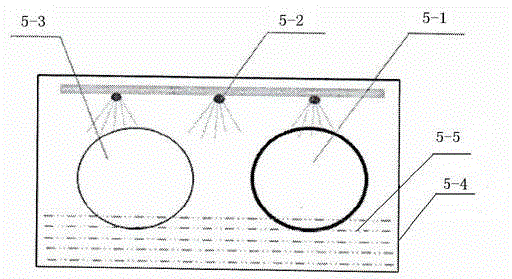

[0020] Such as Figure 2-5 As shown, 5-1 is the main drive wheel of the excess length setting wheel, 5-2 is the cold water sprinkler, 5-3 is the splitting wheel of the excess length setting wheel, 5-4 is the cold water tank shell, and 5-5 is the cooling water , 5-6 are external cold water pipes.

[0021] The optical fiber enters the head of the extruder (1) and is extruded onto the PBT bundle tube, then passes through the hot water tank (2) and the hot water tank (3) to cool and form, and then is drawn by the main traction wheel (4) and enters the cold water tank (5) ), the cooled optical fiber bundle tube is taken up on the take-up reel driven by the automatic take-up system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com