Torque pulsation restraining system and method of permanent magnet brushless direct current motor

A permanent magnet brushless DC and pulsation suppression technology, which is applied in the direction of torque pulsation control, can solve the problem of large torque pulsation, and achieve the effect of eliminating the increase of commutation torque and suppressing commutation torque pulsation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

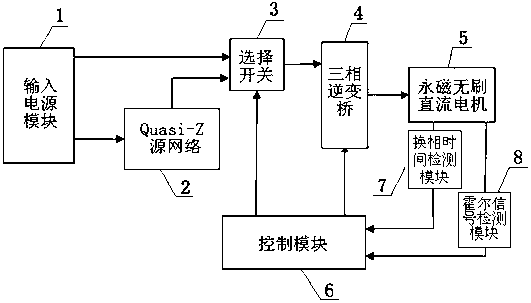

[0019] Such as figure 1 The structure diagram of the permanent magnet brushless DC motor torque ripple suppression system is shown, including: input power module 1, Quasi-Z source network 2, selection switch 3, three-phase inverter bridge 4, permanent magnet brushless DC motor body 5, A control module 6 , a commutation time detection module 7 , and a Hall signal detection module 8 .

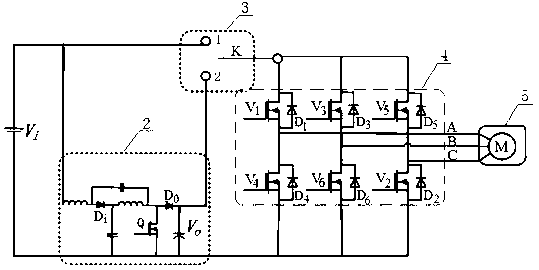

[0020] Such as figure 2 The shown Quasi-Z source network 2 is used as a commutation auxiliary power supply and plays a role of voltage regulation, and is composed of a connection circuit of two diodes, a switch tube Q, three capacitors and two inductors. DC power supply Vi For the input voltage provided by the Quasi-Z source network, the control module outputs a control signal to adjust the duty cycle of the switch tube to adjust the output voltage value of the network, and finally in order to adjust the voltage value required during the commutation period of the permanent magnet brushless DC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com