X-ray multilayer film structure aiming at response of multiple working energy points

An X-ray and multi-layer film technology, applied in the field of X-ray microscope structure for plasma diagnosis, can solve the problems of increasing subject cost and development cycle, spending a lot of time on installation and disassembly, etc., to reduce the ICF physical experiment cycle and increase the coating film. Difficulty, the effect of reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

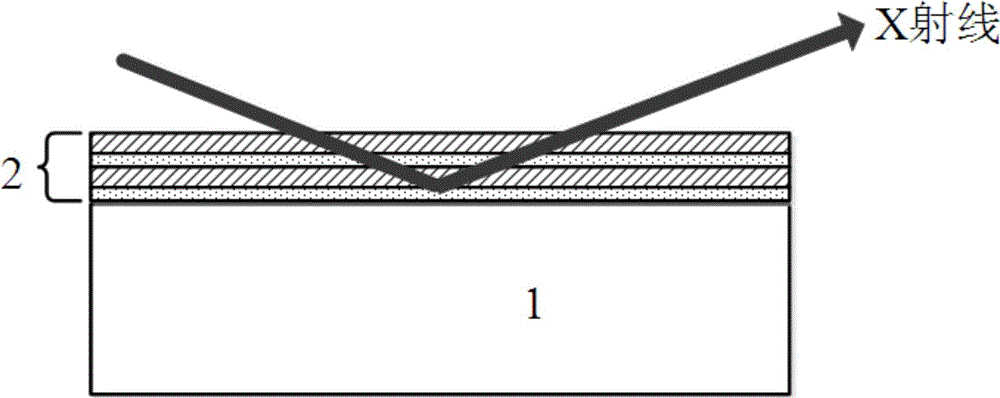

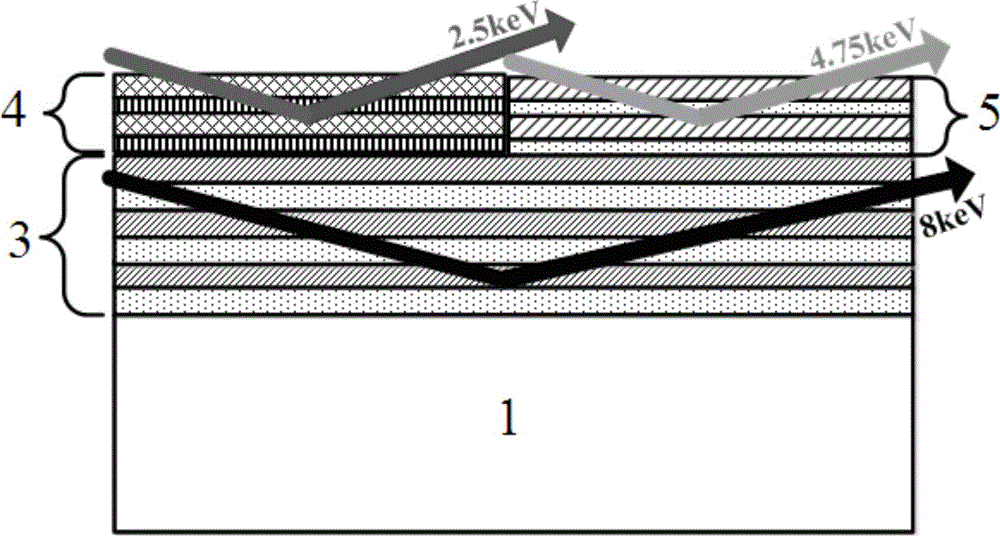

[0029] An X-ray multilayer film structure responding to multiple working energy points, including a KB objective lens coated with multiple film systems responding to X-rays responding to different energy points. like figure 2 As shown, the upper surface of the KB objective lens substrate 1 is coated with the film system C3, and the film system A4 and the film system B5 are coated on the upper surface of the film system C3 at the same time, and the film system A4 and the film system B5 are arranged side by side. Film system A, film system B or film system C are all multilayer film systems, selected from periodic multilayer films, non-periodic multilayer films or transverse gradient multilayer films. In this embodiment, film system A is specifically a Cr / C periodic multilayer film with a thickness of 7.88nm, a thickness ratio of 0.4, and a period of 20, and film system B is specifically a W / C periodic multilayer film with a thickness of 3.9nm. The thickness ratio is 0.42, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com