Semiconductor element and its producing method

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of embedded MIM capacitor limitation, chip area reduction, and inability to provide capacitance value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

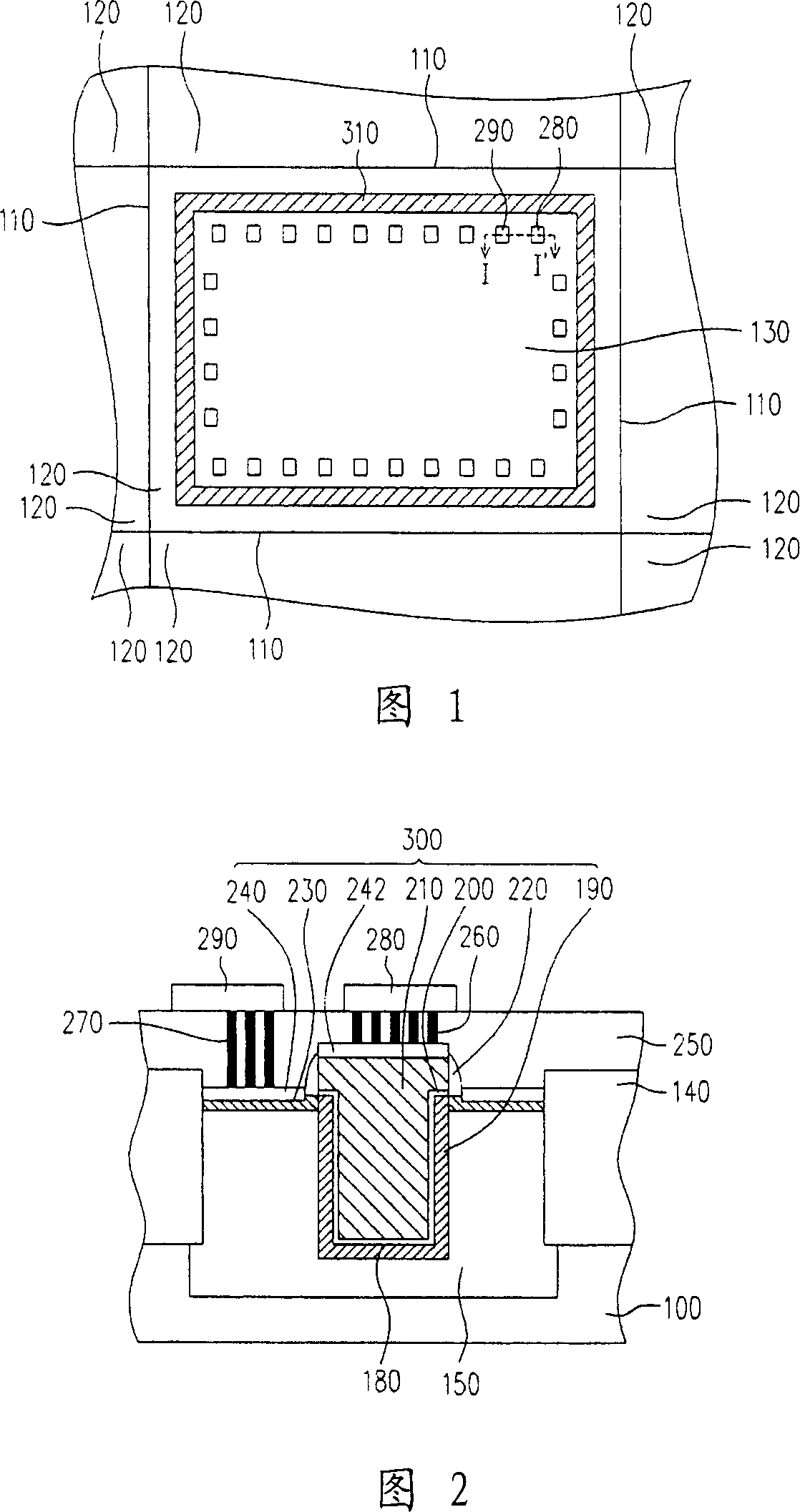

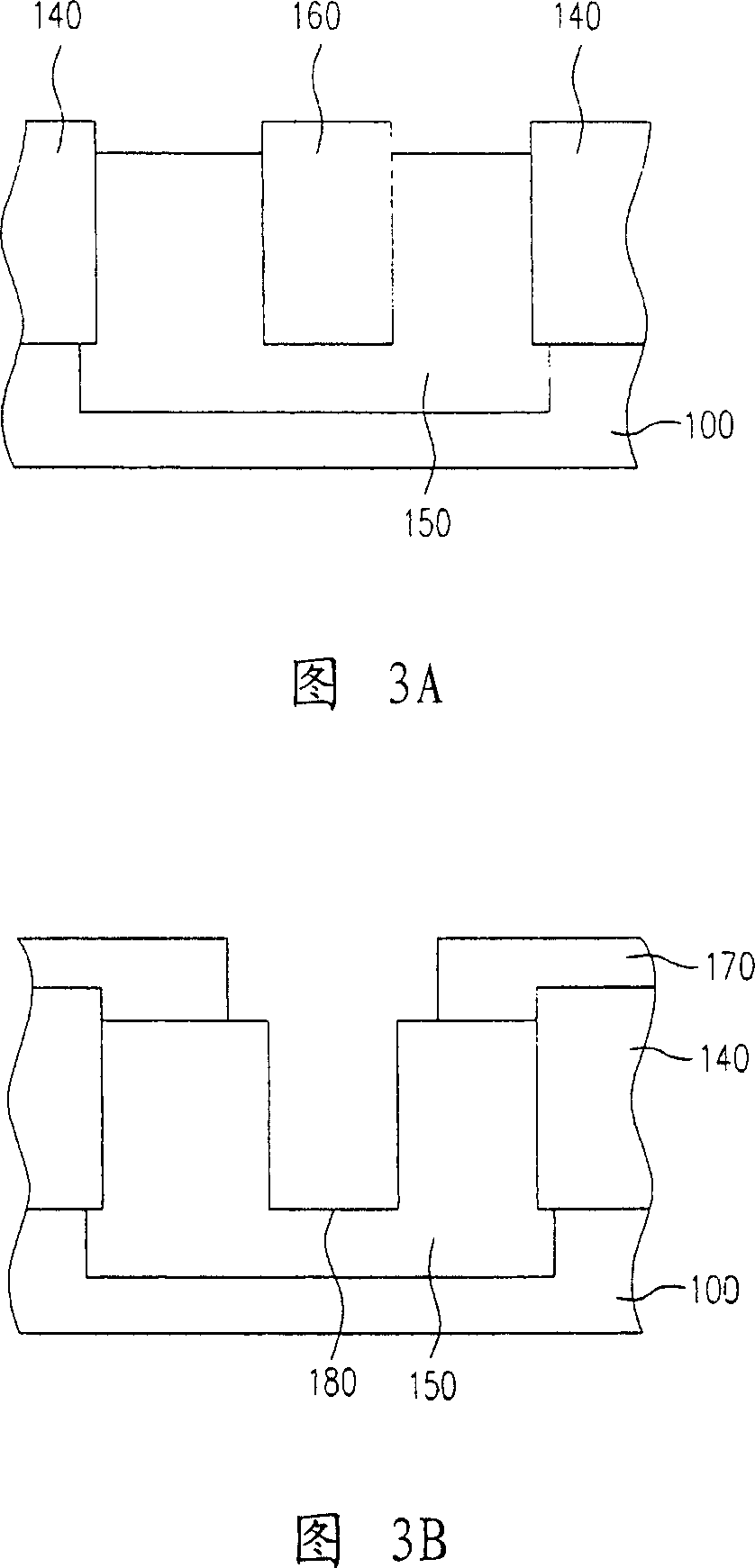

[0048] Fig. 1 is a top view of a semiconductor element of a preferred embodiment of the present invention. Referring to FIG. 1 , the semiconductor device of the present invention is composed of a substrate 100 , a plurality of pads and a trench capacitor 300 . There are a plurality of dicing lines 110 on the substrate 100 , and the dicing lines 110 divide the substrate 100 into a plurality of chips 120 . That is, the area divided by the dicing line 110 is the chip area to be diced in the future. A peripheral area of the chip 120 has a plurality of bonding pads, including a bonding pad 280 and a bonding pad 290 . The trench capacitor 300 shown in FIG. 2 is disposed under the pad, or in the area 310 between the pad and the cutting line 110 . In this embodiment, the trench capacitor 300 located under the pads 280 and 290 is taken as an example for illustration.

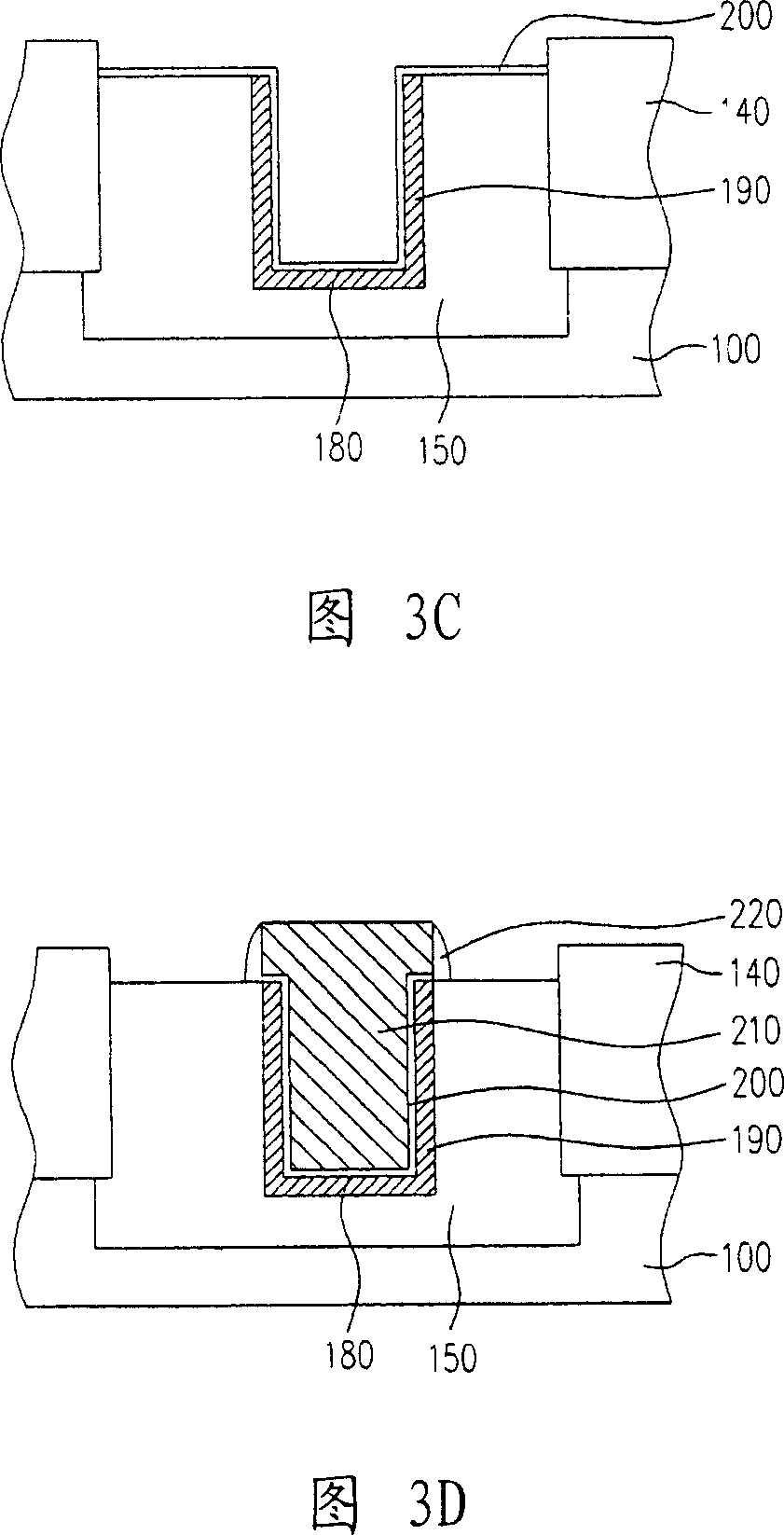

[0049]Please continue to refer to Fig. 2, which is a cross-sectional view along the section line I-I' in Fig. 1 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com