Contact system of a circuit breaker

A contact system and circuit breaker technology, applied in the directions of circuit breaker contacts, circuit breaker parts, etc., can solve the problem of serious damage to the connecting part and the connecting part, poor insulation and compressive strength of the circuit breaker, and the forming process of the moving contact piece. High problems, to achieve the effect of low production process requirements, good stability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In the following, the present invention will be further described by using the following embodiments in conjunction with the accompanying drawings.

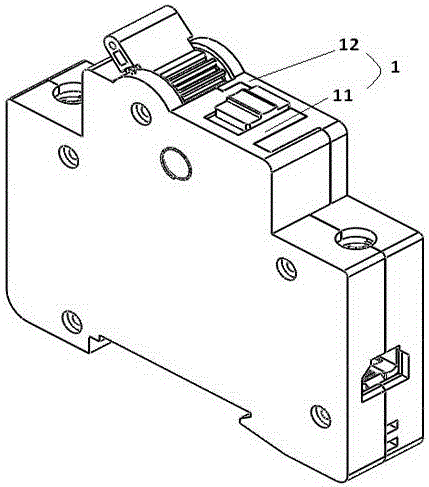

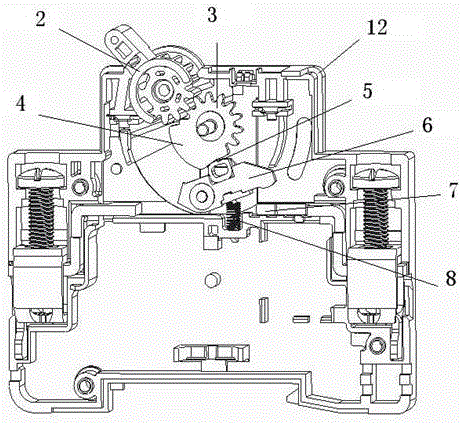

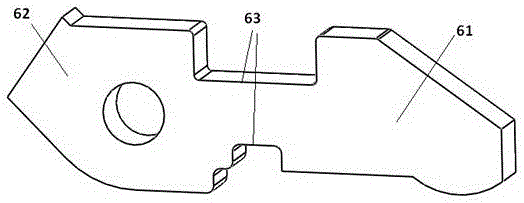

[0025] Such as figure 1 , figure 2 Shown is a specific embodiment of the contact system of the circuit breaker of the present invention, which includes a static contact 7 fixedly connected to the housing 1 and a moving contact 6 rotatably connected to the housing 1, the moving contact The head 6 realizes connection and disconnection with the static contact 7 driven by the operating mechanism; the operating mechanism includes a handle 2 and a contact gear that are respectively axially connected to the housing 1 and connected through gear transmission. 3. It also includes a contact support 5 fixedly connected to the movable contact 6, and a reaction force spring 8 located between the housing 1 and the movable contact 6; wherein, the contact gear 3 There is a cam driving part 4 on it, and under the elastic force of the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com