Vertical substrate conveyer

A transfer device, a vertical technology, applied in the field of vertical substrate transfer devices, can solve the problems of carrier pollution, increase carrier maintenance and construction costs, destroy the preset accuracy of the carrier, etc., to reduce the walking distance and avoid pollution and cleaning and maintenance costs, and the effect of increasing substrate capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

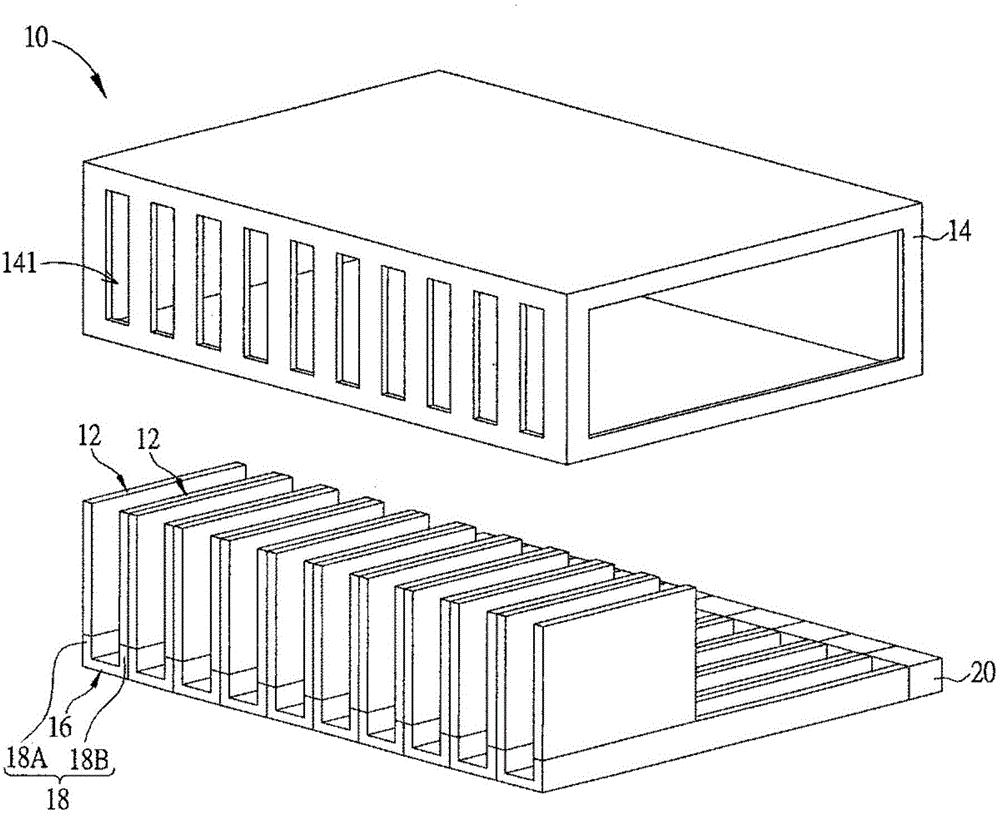

[0022] see figure 1 , figure 1 It is a schematic diagram of a vertical substrate transfer device 10 according to an embodiment of the present invention. The vertical substrate transfer device 10 operates in a vacuum environment, such as a high-temperature vacuum process environment preferably applied in a plasma system, and is used to move a substrate 12 from a transfer chamber to a process chamber. Wherein the substrate 12 is a large-size substrate of more than five generations. The vertical substrate transfer device 10 includes a cavity 14 , a plurality of cassettes 16 and a plurality of storage tanks 18 . The present invention has the function of accommodating multiple substrates 12 at the same time. For example, the vertical substrate transfer device 10 may include ten cassettes 16 and twenty storage slots 18, and each cassette 16 is movably arranged on the Inside the cavity 14 , each cassette 16 is provided with two storage slots 18A and 18B, and each storage slot 18 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com